- What is a hydrogen flow meter and how does it work?

- Why does hydrogen gas flow measurement matter in the hydrogen economy?

- Why is a hydrogen flow meter important for electrolysers?

- Which role do hydrogen flow meters play for fueling of fuel cell vehicles with hydrogen?

- Which are the different flow meter types and operating principles?

Browse all hydrogen flow meters on our marketplace!

What is a hydrogen flow meter and how does it work?

- A hydrogen flow meter is a technical component that not only measures the flow rate, but very often the flowing pressure and temperature of the hydrogen at the flow meter. It uses this pressure and temperature data to calculate the flowing density and/or speed of sound of the medium, in order to calculate the mass (or volumetric) flow rate of hydrogen being delivered. Thus, a more correct technical term for this device is “hydrogen mass flow meter”.

- Hydrogen flow meters are used in hydrogen applications that require an accurate measurement of hydrogen flow, such as electrolysers, or hydrogen refueling applications.

- The Hydrogen flow meter must use an accurate (and repeatable) principle of operation to obtain an exact hydrogen mass flow measurement.

- The installation must be considered very carefully, allowing for sufficient upstream and downstream straight lengths, where required. Installation must account for the rigidity of the connecting pipework and the mounting surface.

- Pressure and temperature effects on the flow meter’s materials of construction (stiffness and internal dimensions) must also be taken into account when making the flow calculations.

Why does hydrogen gas flow measurement matter in the hydrogen economy?

The use of hydrogen obviously requires accurate measurement.

- Hydrogen is needed to provide a safe, economical, reliable and predictable fuel source for heating, transport and electricity supply. The consumption of hydrogen needs to be measured.

- The storage of excess renewable power in the form of hydrogen is recognised as a higher priority with each passing day producing more environmental, social and political challenges.

- Green Hydrogen is generated by electrolysis of water using green electricity generated by solar and wind energy. These renewable energy sources are themselves unpredictable. Hydrogen can act as an energy storage medium for use at night, on less windy and less sunny days. Many hydrogen storage systems incorporate a hydrogen gas flow meter.

Why is a hydrogen flow meter important for electrolysers?

- Electrolysers reduce their efficiency over time, so a reliable and accurate flow meter is an essential tool which can be used to monitor actual output and compare it with the theoretical output. The operator can then act to perform timely maintenance, to ensure that maximum output is achieved, minimising the cost per kg of hydrogen generated.

- Without a flow meter, or one which is accurate and reliable, this maintenance can be mis-timed or jeopardised. The critical factor in electrolyser flow meter performance is the ability to operate at relatively low pressures (less than 35 bar). Having a flow meter with a low permanent pressure drop is therefor an important factor for this process.

Which role do hydrogen flow meters play for fueling of fuel cell vehicles with hydrogen?

- Once generated, hydrogen can be pressurised and stored, prior to use as a fuel for vehicles. The process of fueling a vehicle with hydrogen is quite different to that with standard petroleum products, because the fuel is a compressible gas, compared to a non-compressible liquid.

- At the start of fueling, the vehicle tank pressure is low (1-2 bar) and the fueling system pressure is high (+700 Barg). When the loading process begins, hydrogen flows through a loading nozzle, at a relatively high flow rate, driven by the system pressure. It is not driven by a constant flow rate pump, which is used for conventional fuels. For this reason, the fueling rate slows as the tank pressure builds and the system pressure falls. This can sometimes lead to a two-stage fill being required, to let the system pressure build up again between stages. The pressure and temperature of the gas constantly changes during this process, so the flowing density varies constantly as the tank is being filled.

- All through the system, pressure and temperature is changing, due to flow control valves, heat exchangers and compressors. A very strong understanding of the flowing density is therefore required, at the flow meter, so that an accurate hydrogen mass flow rate and total can be calculated. Without an understanding of the flowing density, the mass flow rate can be inaccurate. For example, at 350 Barg and 20 Deg C, each 1% error in the gas density calculation will produce a 0.5% error in the gas mass flow rate. A flow meter or system which monitors the pressure and temperature at the flow meter is an important requirement, so that accuracy can be maintained.

Which are the different flow meter types and operating principles?

Flow meters operate on many principles, but generally those with no moving parts are preferred, so that wear of critical parts does not become a source of error in the measurement process. A hydrogen gas mass flow meter with no moving parts can operate according to the differential pressure principle. Alternatively it can be of the coriolis mass flow meter type, or the ultrasonic flow meter type.

1. Differential Pressure Flow Meter (DP Flow Meters)

- A DP flow meter creates a small differential pressure across the meter using the Bernoulli principle.

- This type of hydrogen flow meter relies on a change in the flowing area within the meter body. By measuring the differential pressure across this dimensional change, as well as the flowing pressure and temperature at the meter, an accurate flow rate can be computed and corrected for density variations. DP flow meters measure the hydrogen mass and volumetric flow rate.

- DP meters tend to have a medium to low differential pressure loss. Some differential pressure flow meters, such as those using orifice plates, require significant (19 to 40D) upstream and downstream straight lengths. Others, such as DP cone meters cause a degree of self-conditioning (removal of swirl) keeping installation lengths to a minimum. Some designs include the required straight lengths, already built into the meter body. DP Cone meters must be calibrated in hydrogen, or some other gas and the flow calculation must use the flowing pressure and temperature at the meter.

2. Coriolis Flow Meter

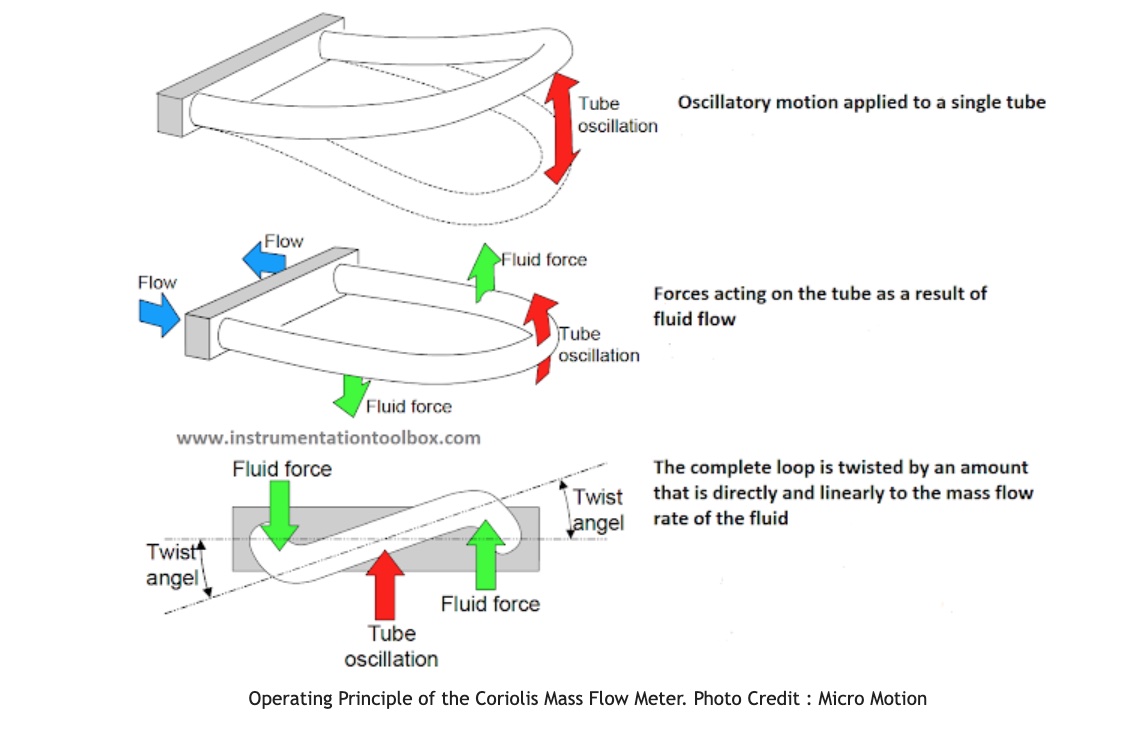

- Coriolis meters use the coriolis principle which relies on the movement of fluid though vibrating tubes to directly calculate the hydrogen mass flow rate. If the density of the fluid is also calculated using the flowing pressure and temperature, the volumetric flow rate can also be obtained. For this reason, hydrogen is often traded in units of mass, compared to volume for petrol or diesel.

- A coriolis mass flow meter measures the mass flow rate directly, so knowledge of the density of the hydrogen is not a requirement. Coriolis meters rely on vibrating tubes to sense the flow rate. At high pressures or low temperatures, the stiffness of these relatively thick walled tubes is affected, so a coriolis meter must take this into account within its flow calculation. A coriolis meter does not require any straight lengths, but it does have the highest differential pressure loss across the meter. Coriolis meters must be mounted in a position, so as to avoid vibration of the meter and stress on the incoming and outgoing pipework. Coriolis meters tend to be costlier than other meter types and should be calibrated with hydrogen or some other gas to maintain accuracy.

For more information on coriolis flow meter see Instrumentationtoolbox.com

3. Ultrasonic Flow Meter

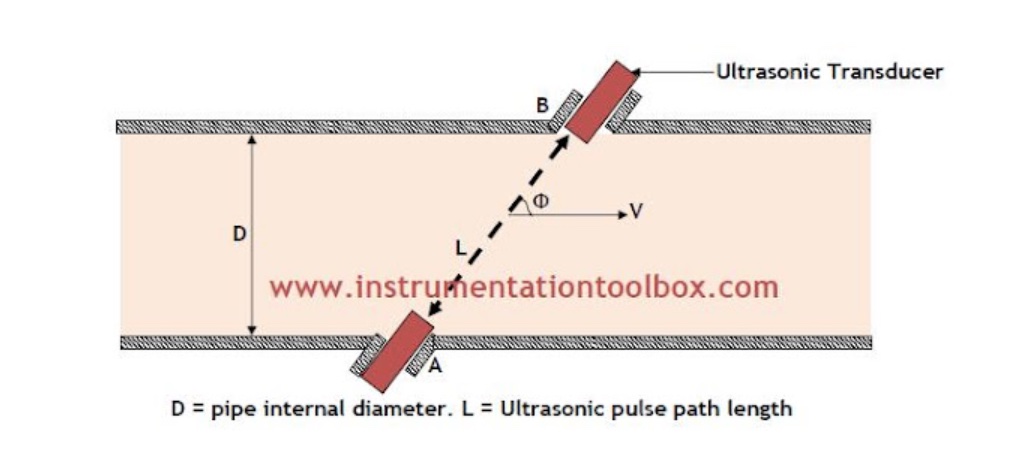

- Ultrasonic flow meter could also be used, but these are still in early stages of development. They operate on the principle of measuring the time taken for an ultrasonic signal to travel across the flow.

- The meter first measures the time taken for a signal to cross the flow path, when transmitted in the direction of flow. It then reverses the signal direction and transmits the signal against the flow, again measuring the time required. The first time is lower than the second, because the signal is flowing with the current. The difference between both of these time measurements is then used, along with the speed of sound of the medium, to calculate the flow rate. As the pressure changes, the density of hydrogen and the speed of sound also changes. An ultrasonic hydrogen flow meter has the lowest pressure drop across the meter, because this design is effectively an open pipe. Ultrasonic meters also require significant upstream and downstream straight lengths, in order to generate conditioned flow (without swirl), otherwise the measured flow rate could be adversely affected. Ultrasonic meters should also ne calibrated with hydrogen, or some other gas, to maintain accuracy.

For more information on ultrasonic flow meters see Instrumentationtoolbox.com

Content contributed by GM Flow

GM Flow are experts in measurement of the flow rate of gases, historically natural gas and nitrogen, but we now excel in hydrogen and CO2. Our technology is designed and built in Scotland, with over 100 years of experience within our team. With less than 1 bar of pressure loss, and no moving parts, our latest product Hy-Cone™ is designed specifically for Hydrogen. The low pressure loss across Hy-Cone™ maximises hydrogen throughput in vehicle fueling applications. For electrolyser applications, these devices monitor hydrogen output rates, maintaining maximum electrolyser efficiency over time.

Last update: 15.1.2023