Hydrogen Filling Station GFS9000

Maximator GmbH- Hydrogen filling station has revolutionary compression technology

- Plug&boost design with capacity of 10 kg/hour at 900 bar

- Designed for maximum efficiency

- Very compact solution design inside a 10 ft container

- Refueling nozzle and hose packages available on request

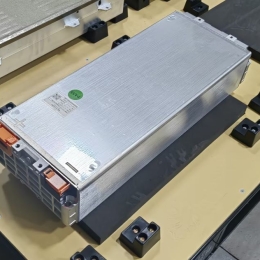

Hydrogen filling station GFS9000

- The Maximator GFS series are standalone hydrogen filling stations for small and medium scale applications.

- With the new GFS technology, Maximator is proud to introduce maybe the most efficient way of hydrogen compression.

- The GFS solution is based on X-TOWER with all the advantages of this revolutionary compression technology.

- The GFS is a plug & boost solution from Maximator which is covering all requirement.

- The interface connections for the customer are reduced to a minimum: H2 supply, H2 outlet, N2 supply and electrical power. All other modules for a safe and efficient compression are already integrated.

- A web-based access to the control system offers independent control with your mobile PC or smartphone.

- Maximator designed this hydrogen filling station especially for small and medium scale filling processes for e.g. Hydrogen refueling in laboratory applications, drones, small fleet FCEV´s and home energy storage solutions and many more.

Key features

- Flexibility: With the X-TOWER you are planning the future. Our solution can be adapted to new challenges by changing, adding or removing X-Modules. The modular design of hydrogen filling station allows countless combinations of X-Modules to cover many different applications and requirements.

- Efficiency: With the new frequency converter controlled complete closed hydraulic drive concept of our EHB-Series we are providing the most efficient way to compress gases.

- Efficient hydraulic drive with less oil volume

- Direct separation between process gas and hydraulic

- Flushing concept integrated

- Quite drive technology

- Cooling: Intelligent and efficient new cooling concept keep the gas temperature in hydrogen filling station under control with minimum energy consumption.

- Safety: Purging, temperature & pressure control, gas detection, active ventilation are only some of our safety features of the new X-Tower series.

- Integration: „Plug & boost“. A web based access to the control system offers independent control with your mobile PC or smartphone. Our X-Tower series is prepared for IoT integration to improve processes and provide more information about the compression process than ever before.

- Smart automated pressure generation

- Innovative maintenance concept

- Clean hydrogen compression

- Modular system design

Application areas

- Hydrogen pressure generation up to 900 bar

- Laboratories

- Universities

- Research & development

- Calibration product acceptance test

- Small & medium scale refueling application

- Hydrogen gas transfer

- Hydrogen recovery

- Compression after electrolyzing

- Workshop or test field area

Contact us

- Contact us and tell us about your requirements. We will provide the product with performance and safety you expect.

| Brand | Maximator |

| Type of Cooling | Water |

| Max Pressure (in bar) | 900 |

| Manufacturing Readiness (MRL) | 0 |

| Technology Readiness (TRL) | 0 |

As an internationally leading company specialized in high-pressure technology, Maximator develops high-performance products and solutions for a variety of uses and applications in the field of high pressure testing and production equipment, hydraulics and pneumatics. Maximator has many years of experience with components, power units and test systems especially for hydrogen applications Many components for the development of this future technology are exposed to extreme stresses. Maximator meets this challenge with innovative high pressure test technology for hydrogen components such as valves, pipes or CGH vessels. We can carry out all legally prescribed testing on pressure bearing components with our test technology: from individual acceptance to type approval testing. We also offer gas control technology for hydrogen applications - approved effective and reliable technology for automotive manufacturers and suppliers.