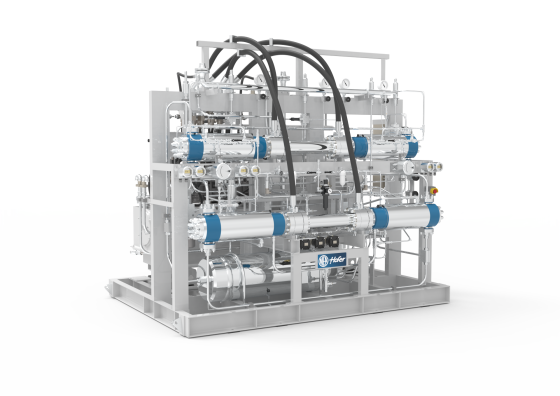

NEA|HOFER TKH Hydrogen Piston Compressor

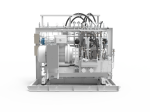

NEUMAN & ESSER- hydraulically driven hydrogen piston compressor

- designed and manufactured for oil-, leakage- and technically abrasion-free compression to fuel hydrogen vehicle tanks of 1,000 bar max.

- for the compression of non-corrosive gases, such as hydrogen, helium, argon, nitrogen, carbon-dioxide and ethylene

- for small volume flows and high pressures, as e.g. required for light vehicle fuel stations

- perfect complement to ensure flexibility of demand and energy security with hydrogen

NEA|HOFER TKH Hydrogen Piston Compressor

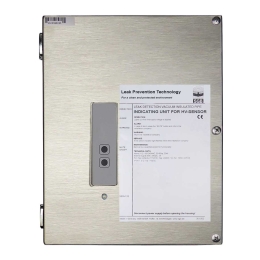

- NEA|HOFER TKH are available either as complete units, - including a base frame, a power unit, pulsation dampers, coolers, (automatically or manually-operated) valves, instruments and a control unit (optional), - or without peripheral equipment, ready to be installed in your system.

- All NEA|HOFER TKH are subjected to a test run under load at NEUMAN & ESSER, during which the operating data are recorded and documented.

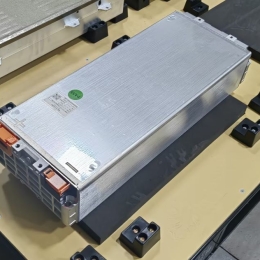

Key Features

- maximum discharge pressure of approx. 4,200 bar (60,000 psi)

- for start-stop applications (volatile scenarios)

- number of strokes per minute easily to be controlled via the hydraulic control unit to ensure efficient capacity control

- exceptionally easy to maintain: piston packing to be replaced in 10 to 30 minutes depending on compressor size

- hydraulic unit is connected through a gastight wall

- explosion-proof hydraulic units available on special request

- small footprint

- due to the arrangement of stages above one another, ideally suited for the installation in containers

Application Areas

- Hydrogen Services

- Hydrogen Refueling Stations (HRS)

Project Cases

- more than 100 units for H2 services and HRS to refuel mainly light vehicles and buses installed in Europe, Asia and North America since 2005

- installation for HRS to refuel busses during Olympic Winter Games in 2002

- market leader in installations for HRS of light vehicles in South Korea

Contact Us

Please fill out the contact vendor form to get in touch with us.

| Brand | NEUMAN & ESSER |

| Max Pressure (in bar) | 3000 |

NEUMAN & ESSER stands as the industry’s reliable partner, propelling the energy transition through its integrated solutions for the energy infrastructure of tomorrow.

Our compressor solutions including our in-house sealing technology are utilized extensively when it comes to industrial gas processing. Catering to the emerging hydrogen economy and green gas industry.

The product portfolio also includes hydrogen production systems such as electrolyzers and steam reformers, holding the key technologies for future demands of clean energy. With over a century of expertise, in hydrogen compression, NEUMAN & ESSER has established itself as a leading expert in the complete H2 value chain.

When it comes to bringing challenging projects to life, NEUMAN & ESSER can serve as your trusted advisor. We offer comprehensive support throughout the entire project lifecycle, starting from the assessment of potential sites and the feasibility and financing. Our expertise extends through engineering, construction and commissioning to digitally supported 360° service throughout the operation.

Thanks to our family business’s continuity spanning nearly 200 years and our extensive network of production sites, sales & service centers worldwide, more than 1,600 employees are dedicated to solving our customers' mission critical challenges in long-term partnerships.

NEUMAN & ESSER champions the transition of the economy by undertaking ambitious projects aimed at shaping a future powered by renewable energy sources.