Screwed Bonnet Needle Valve - H-99 Series

UCT Fluid Solutions- The H-99 series needle valve offers a general service valve of rugged design and construction.

- Manufactured in 316 Stainless Steel Structure to suit a wide range of services.

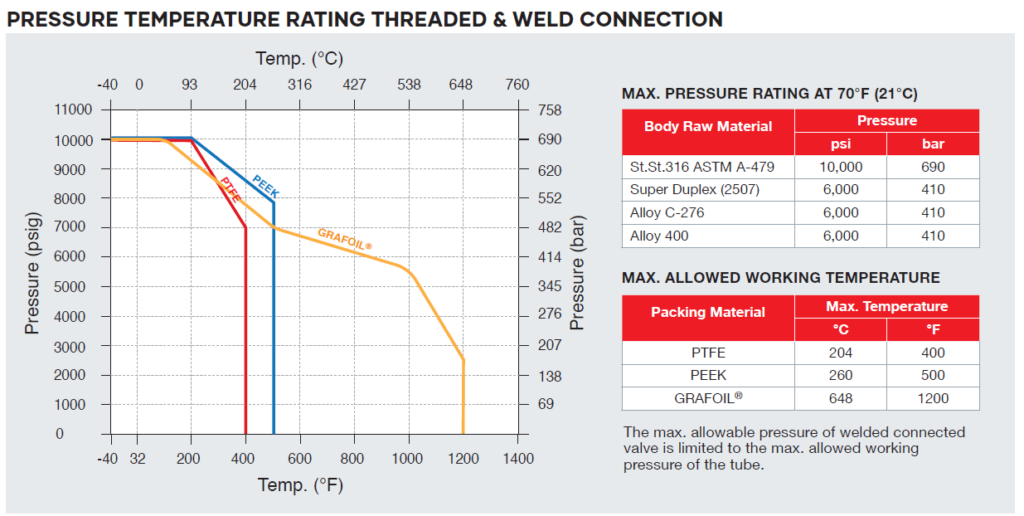

- MAWP up to 10,000 psi (690 bar)

- MAWT up to 648°C (1200°F)

- Available in sizes 1/4” to 1” (6mm to 25mm)

- Variety of stem types- V, R, and NR

Screwed Bonnet Needle Valve - H-99 Series

- The H-99 Series offers a general service valve of rugged design and construction. It is available in stainless steel to suit a wide range of services. Capable of withstanding high-pressure (10,000 psig max) and high temperature.

- This valve is typically used in severe environments, high-pressure sampling systems, high-pressure shut-down systems and test stands.

- Every H-99 series needle valve is cleaned in accordance with Standard Cleaning and Packaging (procedure 8184). Oxygen Clean & Lubricant-Free Cleaning and packaging, in accordance with Special Cleaning and Packaging (procedure 8185), is available as an option.

- The H-99 series needle valve design has been tested for proof and burst. Every H-99 needle valve is factory tested with nitrogen at 1000 psi (69 bar) for leakage through the packing and seat. The maximum allowable leakage across the seat is 0.1 std cc/min. No detectable leakage is allowed during shell test.

Key features

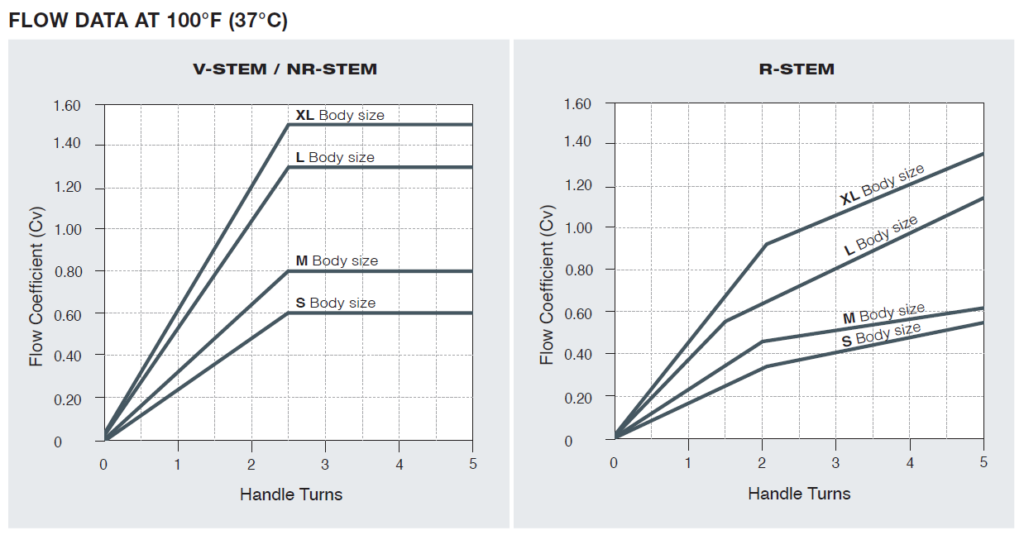

- UCT Fluid Solutions needle valves are available with a choice of stem-tip options to allow greater flexibility: V-stem, R-regulating stem, and non-regulating stem

- Packing bolt for easy panel mounting, no packing disassembling is required

- Stem special diffusion surface hardening provides the best galling resistance and protection from wear and corrosion.

- The H-99 stem has ceramic stem ball tip option - superior hardness prevents deformation of the sealing tip and wear, significantly increasing the lifetime of the product.

- Available in 316 stainless steel, super duplex, alloy 400 and alloy C-276 construction

- Flow coefficient (Cv) 0 to1.5

- 3 types of packing materials: PTFE, PEEK and GRAFOIL®

- Available in 4 body sizes (S, M, L, XL)

Product charts

Application areas

- Electrolysis

- Electricity generation wind and solar

- Hydrogen storage

- Fuel cell stations

- Process system control and shut-off

- Control panels

Contact us

- Please see the technical datasheet under downloads for mounting configuration of screwed bonnet needle valve (H-99 series). Fill out the contact vendor form to contact us today.

| Max Pressure (in bar) | 690 |

UCT Fluid Solutions is a leading global manufacturer and supplier of industrial high-performance high-performance flow control systems. Our broad portfolio covers the diverse needs of the various needs of the hydrogen industry in the industrial and automotive sectors automotive, with special valves, fittings, hoses, and customised solutions. Our ball valves, needle valves, and manifolds are certified according to ISO 15848-1 and ensure the lowest fugitive emissions and maximum safety when handling hydrogen. Our tube fittings are EC79-certified for use in vehicles and are tested annually by an independent laboratory. are rigorously helium tested annually by an independent laboratory to guarantee our customers that we meet the highest industry standards. By fostering innovation and creativity, UCT Fluid Solutions has developed patented products and simplified products and simplified technical solutions to meet our customers' requirements.