Blowers

expand_more

Connectors

expand_more

Control Units

expand_more

Electrolyser Stacks

expand_more

Electrolytes

expand_more

Fuel Cell Filters

expand_more

Fuel Cell Stacks

expand_more

Gauges

expand_more

Heat Exchangers

expand_more

Hydrogen Bearings

expand_more

Hydrogen Flow Meter

expand_more

Hydrogen Tanks

expand_more

Level Indicators

expand_more

Sensors

expand_more

Separators

expand_more

Switches

expand_more

Transmitters

expand_more

Valves

expand_more

Air Actuated Valves

Air Flow Control Valves

Angle Seat Valves

Ball Valves

Cathode Isolation Valves

Check Valves

Control Valves

Cryogenic Valves

Flow Control Valves

Globe Valves

Hydrogen Back Pressure Regulators

Hydrogen Fuel Cell Pressure Regulators

Hydrogen Pressure Reducing Valves

Hydrogen Pressure Relief Valves

Hydrogen Pressure Solenoid Valves

Hydrogen Tank Valves

Needle Valves

On Tank Valves

Plunger Valves

Proportional Valves

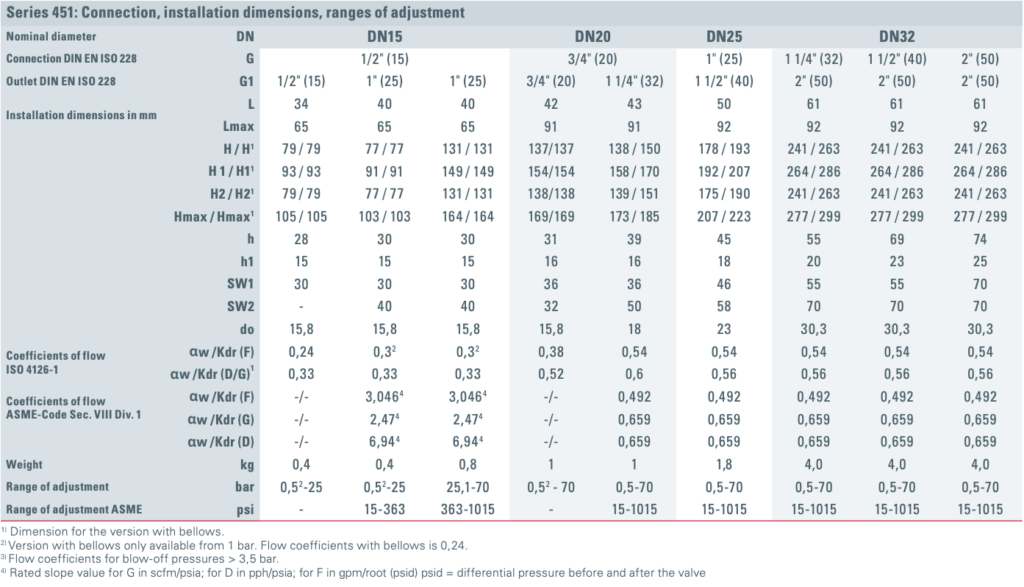

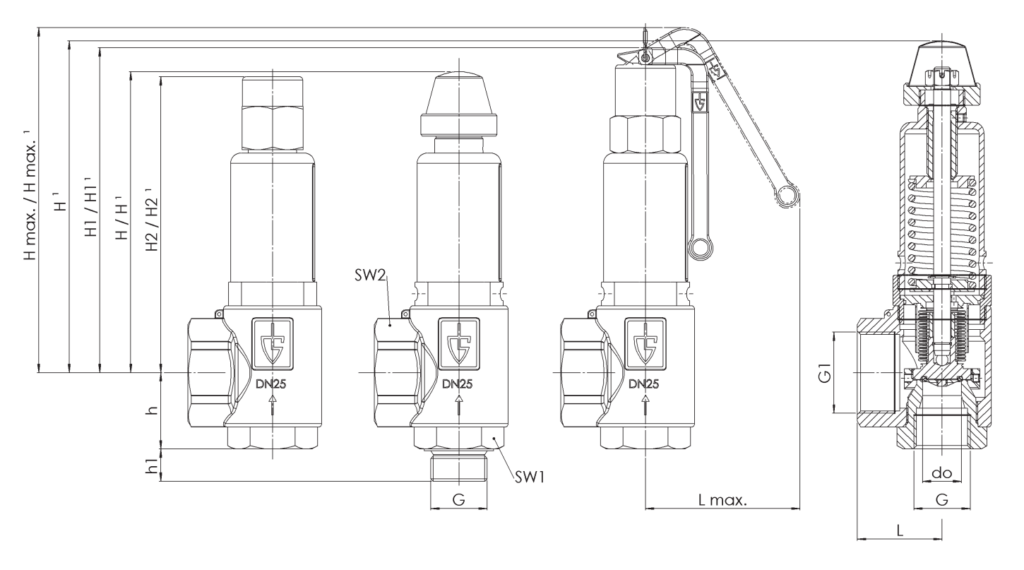

Safety Valves

Shut-Off Valves