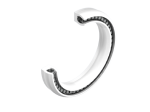

Piston or rod seal for high pressure and static sealing

ElringKlinger Kunststofftechnik GmbH- Temperature range depending on application from -260°C to +260°C

- Outstanding dry-running characteristics

- Low wear and low friction

- No stick-slip even with low sliding speeds

- No volumetric change by swelling or shrinkage

Our spring energized seal

Dynamic applications that are required to function without lubrication put a greater emphasis on seal design and the materials being used. Especially in the case of dry running rod seals which are subject to high temperature and high pressure conditions, PTFE compounds combined with advanced fillers must be selected in order to achieve efficient performance and a long service life. Advanced polymer technology combined with many years of practical experience allow our team of engineers to select the correct combination of material and seal geometry for the application in question. Often reciprocating but also in rotary installations, maintaining a high level of seal efficiency by minimising wear allows our seal solutions to achieve outstanding levels of performance and longevity. For sealing rotary and swiveling applications the choice is a URF rod seal with clamping flange.

Key benefits

- Outstanding dry-running characteristics

- Low wear

- Low friction

- Variable friction conditions through choice of spring characteristics

- Extremely low breakaway forces even after prolonged down times

- No stick-slip even with low sliding speeds

- High dimensional stability

- High chemical and thermal resistance

- No volumetric change by swelling or shrinkage

- Compact seal, suitable for O-ring assembly spaces according to ARP 568 A, DIN 3771 and ISO 3601/1

- Good cost benefit ratio

- Dimensions from Ø 2 to Ø 3000 mm available

- Very good wiping effect with abrasive media

Application areas

- Electrolysers

- LPG valves

- Valves for technical gases such as oxygen or hydrogen

- Fuel cell valves

Operating parameters

- T = –260°C to +260°C depending on application

- p = up to 250 bar and more

- v = 15 m/s for reciprocating movements

- v = 2.5 m/s for rotating movements

| Brand | ElringKlinger Engineered Plastics |

| Manufacturing Readiness (MRL) | 0 |

| Technology Readiness (TRL) | 0 |

| Max Ambient Temperature (in °C) | 260 |

| Min Ambient Temperature (in °C) | -260 |

Innovations in high-performance plastics - for over 50 years, ElringKlinger Engineered Plastics has been one of the technology leaders for seals, engineering design elements, assemblies and modules. At ElringKlinger, innovation always starts with the material. Due to in-house materials development and compounding, Polytetraflon™-PTFE materials and Moldflon™-thermoplastic materials can be customized. Optimal performance for our customers is achieved not only by means of component optimizations using the Finite Elements Method (FEA) but also by selecting suitable materials.

Latest products