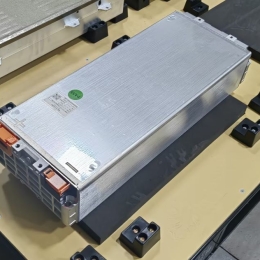

Hydrogen Cylinder H2 Max™ 540L

Advanced Structural Technologies. Inc.- H2 Max™ 540L is Composite Overwrapped Pressure Vessel (COPV) with Superior fast filling properties.

- Ideal for cryogenic applications and rough environment

- Custom hydrogen cylinder diameters fabricated in-house with working pressure of 517 bar

- Transportable without a CDL and HazMat endorsement

Hydrogen Cylinder - Working with Advanced Structural Technologies, Inc.

Advanced Structural Technologies, Inc. (AST) is an industry leading manufacturer, specializing in rotary forging, metal spinning, and flowforming aluminum and other alloys into complex shapes. We have over 150,000 sq ft of manufacturing facilities in Camarillo Oxnard and California. Using our 20 years of experience and knowledge in metalforming, we have expanded into alternative energy with the largest diameter liners/cylinders in the market. We offer a unique range of manufacturing equipment, processes, and engineering expertise, which gives us the ability to innovate and maintain the top quality and excellence that our customers can count on.

Hydrogen Cylinder H2 Max™ 540L description

- H2-MAXTM 540L cylinders are designed for hydrogen storage in various applications for zero-emission and sustainable mobility solutions with service pressures of 517 bar.

- The large diameter and volume of the H2-MAXTM 540L allows for fewer cylinders, valves and PRDs. Thus, minimizing potential leak points due to the reduced number of fittings and connection points required when compared to a traditional hydrogen storage system designed with conventional cylinders.

- AST concentrates on large-diameter Type 3 hydrogen transportation, HFC-applications, marine, rail and the rugged mine applications, where the advantages of a Type III are particularly well suited.

Key features

- One of the largest diameter Type III cylinder for hydrogen applications in the market

- Seamless, one-piece aluminum liner

- Inherent leak before burst failure mode

- Superior heat tolerance for extended cylinder life

- Higher impact tolerance for increased safety

- Faster and complete filling with significant benefits

- Efficient and complete fills in extreme temperatures

- Reduced fueling cost. Superior heat dissipation requires no chilling during filling process

- More complete fueling reduces range anxiety

- Extended life cylinders

- No replacement needed after exposure to high temperatures

- Surpassed testing requirements to meet maximum cylinder life

- H2-Max hydrogen cylinders are uniquely suited for rugged environments, and ideal for compressed cryogenic applications.

- Certified with UN ISO 11515

Application areas

- H2 transport/mobile pipeline

- Material Handling

- Mining equipment

- Rail applications

- Marine applications

- Backup power/storage

Contact us!

Please refer the datasheet for customisation and by pooling our experience, knowledge and technology, we are able to meet your requirements with precision.

| Brand | AST Alternative Energy |

| Type of Tank | Type III |

| Tank Mount Type | Neck Mount, Strap Mount |

| Nom. Oper. Pressure (in bar) | 517 |

| Nom. Tank Pressure (in bar) | 517 |

| Volume Water equival. (in L) | 540 |

| Diameter (in mm) | 673.1 |

| Max Storage (in kg H2) | 17.2 |

| On Tank Valve included | No |

| Manufacturing Readiness (MRL) | 8 |

| Technology Readiness (TRL) | 6 |

| Compliant with | UN ISO 11515 |

Advanced Structural Technologies, Inc. (AST) is a world-leading manufacturer, specializing in rotary forging, metal spinning, and flowforming aluminum and other alloys into complex shapes. Neuman;nead-sso@neuman-esser.de;Founded in 1830, for about a century NEUMAN & ESSER GROUP has been supplying H2 compressor units to industry. Today NEA is a one-stop shop for Integrated Solutions along the H2 Value Chain. The portfolio includes electrolyzers, reformers, compressors, HRS and many other solutions covering generation, distribution and storage. Customers benefit from an OEM with decades of H2 expertise and receive support throughout the lifecycle of a decarbonization project: from greenfield studies, through engineering and manufacturing, to digital integration and 360° service during operation as well as brokerage of green gases.;Die NEUMAN & ESSER GROUP wurde 1830 gegründet und liefert seit etwa einem Jahrhundert H2-Kompressoranlagen an die Industrie. Heute ist NEA ein One-Stop-Shop für integrierte Lösungen entlang der H2-Wertschöpfungskette. Das Portfolio umfasst Elektrolyseure, Reformer, Kompressoren, HRS und viele andere Lösungen für Erzeugung, Verteilung und Speicherung. Kunden profitieren von einem OEM mit jahrzehntelanger H2-Expertise und erhalten Unterstützung während des gesamten Lebenszyklus eines Dekarbonisierungsprojekts: von Greenfield-Studien über Engineering und Fertigung bis hin zu digitaler Integration und 360°-Service während des Betriebs sowie der Vermittlung von grünen Gasen.