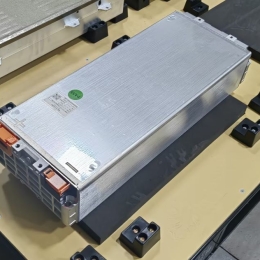

Blowmolded Type 4 Tank Inner Liner

Elkamet Kunststofftechnik GmbH- Wide range of different dimensions possible for blowmolded Type 4 tank inner liner

- Maximum size with length of 2100mm and diameter of 750mm

- The liners boss connector is customizable according to the customers’ specifications

- Various successful projects realized for global OEMs, both in the hydrogen and in CNG industry

- This product is in series production since 2014

Blowmolded Type 4 Tank Inner Liner

- Elkamet manufactures thermoplastic liners of various sizes using rotational and extrusion blow molding processes

- These are used, among other things, as the inner shell of pressure vessels for storing gases and liquids

- Typical applications include hydrogen and CNG tanks

- The thermoplastic liner serves as the inner shell

- Mechanical strength is achieved with the aid of fiber and resin wrapping

- One or more Boss parts are used as valve connections

Features

- Manufactured via extrusion blow molding

- Inner liner made of PA6 or PE

- Inner liner used for tanks with operation pressure up to 700 bar

- Various sizes possible

- Maximum size with length of 2100mm and diameter of 750mm

- The length of the mold can be arranged in a modular system

- The liners boss connector is customizable according to the customers’ specifications

- Showed liner: Formed thread partially with support sleeve in cap and sealing for protection against pollution

- Weight reduction compared to aluminium liner

- Good permeation barrier

- Serial production for automotive sector

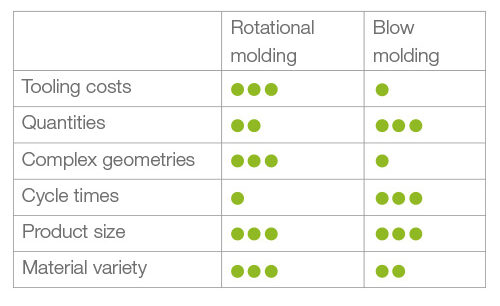

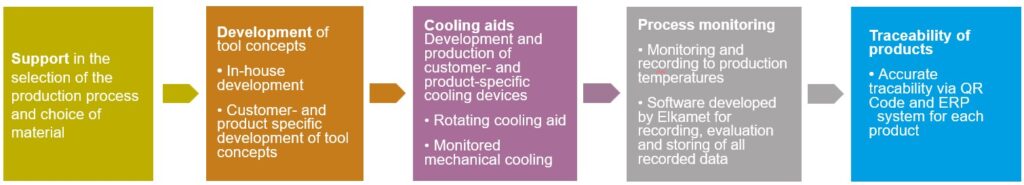

Which process is suitable for your application?

Applications

- Hydrogen (H2)

- Compressed Natural Gas (CNG)

- Nitrogen (N2)

- Gases and liquids in general

Use Cases

- CNG liner for cars / automobile

- H2 liner for busses, trucks and trains

- Liner for aeronautics

- Stationary and mobile H2 storage systems

Competencies

Contact us

- Fill out the form to contact us. We are happy to learn about your requirements.

| Brand | Elkamet |

| Max Pressure (in bar) | 700 |

| Manufacturing Readiness (MRL) | 0 |

| Technology Readiness (TRL) | 0 |

Identifying challenges, finding solutions: with our know-how and experience, we are experts in the field of tank development and manufacturing. Over the past years, we have applied our development skills into developing inner plastic liners for a variety of applications and have evolved as specialists in this area. For many years Elkamet is supplier for the inner liner of CNG tanks and in the recent years also deeply involved in many projects for H2 liners. From our manufacturing facilities in Wilhelmshütte (GER), Myslinka (CZ) and East Flat Rock (US) we each year supply more than 700.000 parts produced in roto- and blowmolding to our customers. All sites are certified according to IATF 16949. Together with you, we develop products, which offer added value and thereby positively boost your business in the long-term.

Latest products