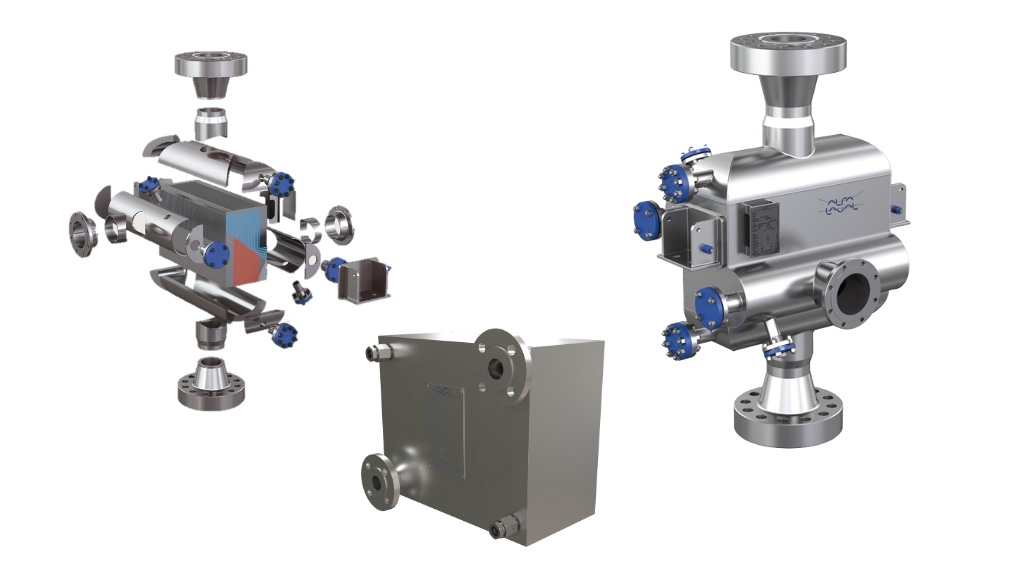

Printed Circuit Heat Exchanger HyBloc

Alfa Laval Mid Europe GmbH- Heat exchanger HyBlocTM is applicable in compression and pre-cooling of hydrogen.

- Faster and safer refueling at hydrogen refueling station.

- Heat exchanger HyBlocTM can operate in temperature range from -196°C to +800°C and pressure range from vacuum to 1250 bar.

- World-wide support with reliable technology since 15 years.

- Alfa Laval provides a fully customized solution with ultra compact design.

Alfa Laval printed circuit heat exchanger PCHE HyBlocTM

- To meet the growing demand for new, high-capacity fueling stations, Alfa Laval introduces the HyBlocTM range of printed circuit heat exchangers.

- These ultra-compact units help minimize hydrogen filling times and dramatically reduce both space requirements and installation costs.

- Alfa Laval’s team of application experts are ready to support you in designing the optimal solution for your system.

- The new Alfa Laval HyBlocTM range of printed circuit heat exchangers (PCHE) are engineered for use as pre-coolers in hydrogen refueling stations, supplying fuels to light passenger and heavy duty vehicles (HDV) such as trucks and buses.

- Thanks to the printed circuit technology, an Alfa Laval HyBlocTM heat exchanger is 85% smaller than a comparable shell-and-coil or shell-and-tube heat exchanger.

- This maximizes flexibility when designing the complete refueling system and the unit is easily integrated, e.g. in the dispenser casing. As opposed to a shell-and-coil or shell-and-tube heat exchanger, there is no need to install a HyBlocTM below ground, which reduces civil work significantly.

- Withstanding pressures of up to 1,250 bar, an Alfa Laval HyBlocTM allows you to design your systems for operation at 350 bar (H35), 700 bar (H70) or higher. The high-pressure capabilities of a HyBlocTM unit ensure short filling times and also makes it future proof in case new standards with higher pressures are developed.

- The HyBlocTM range comprises four models, offering solutions for all capacity needs.

- The safety of Alfa Laval’s printed circuit heat exchangers has been thoroughly proven in several demanding fueling applications such as fuel gas supply for large ships and land-based natural gas supply systems for industrial and domestic applications for more than 15 years.

Benefits

- Zero waiting time between refuelings, thanks to continuous refrigeration loops.

- Ability to operate at very high pressures of 1250 bar and minimum temperature of -70°C, enabling minimal filling times

- It is even ready for future stadards with even higher pressures.

- Ultra-compact, packageable and thermally responsive design with minimal space requirements.

- The small size of the pre-cooler brings extra value when the installation space is scarce, e.g. in urban areas

- Well-proven and safe technology

- Leading supplier with high production capacity and worldwide application support.

Features

- OptiBondTM : A robust and compact solution for high pressure needs. State of the art diffusion welding technology provides the highest durability and thermal efficiency within an ultra compact welded plate heat exchanger.

- PowerDense: Maximum sustainibility under maximum pressures. Improves sustainibility with the smallest metal footprint design that can still contain hydrogen pressures as high as 1250 bar.

- 3DPlate: Prevents clogging under freezing condition. A patented 3D plate pattern maintains high efficiency and maximum uptime when using water based fluid like glycols in cryogenic application.

- ReFuel+: Higher back to back throughput for increased profitability. Low thermal mass in a highly responsive and compact solution enables greater capacity and reduced wait time between customers, extending the number of daily back ot back refuels.

Learn more about the product from our experts

Application areas

- Hydrogen refueling stations (HRS)

- Compression of hydrogen

- Pre-cooling of hydrogen

- Offshore gas compression

- Medium to high temperature long duration energy storage (LDES) processes

Contact us

- We help you select the ideal model according to your cooling fluid, capacity requirements, etc to maximize performance. Fill out the contact us form to fulfill your system requirements.

| Brand | Alfa Laval |

| Type of Heat Exchanger | Printed Circuit Heat Exchanger |

| Max Pressure (in bar) | 1250 |

| Max Ambient Temperature (in °C) | 800 |

| Min Ambient Temperature (in °C) | -196 |

Alfa Laval is an international Swedish company active in the areas of energy, marine, and food & water, offering its expertise, products, and service to a wide range of industries in some 100 countries. With our broad portfolio of thermal and separation technologies we provide solutions for enabling the transition to green hydrogen. In electrolyser production (PEM, Alkaline, or SOEC), we offer efficient plate heat exchangers for cooling electrolytes, hydrogen and oxygen. Our plate heat exchanger portfolio also includes desalination technologies that allow you to use seawater or river water in your production, which is ideal if you operate an offshore plant. And our heat transfer solutions make it possible to recover and reuse waste heat from the electrolyser to desalinate water, or for other sustainable purposes, such as district heating. We are present in both production and storage, with unique solutions for compression and cooling, as well as innovative printed circuit heat exchangers for refueling stations. Alfa Laval has spent decades developing highly efficient and robust plate heat exchanger technologies. From our fusion bonding technique that enables reliable performance at very high temperatures, to gas-to-liquid solutions that can handle extremely uneven flow requirements, we can offer unique technologies perfect for fuel cell development.