Silicone Flat Gaskets for PEM Fuel Cells

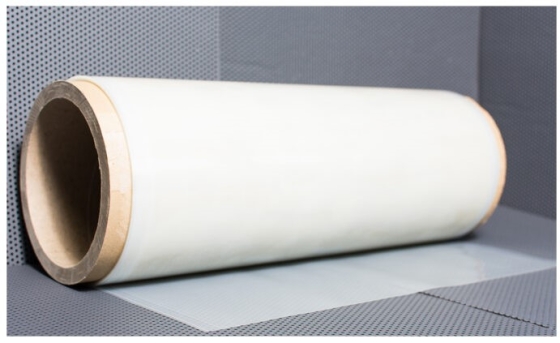

Laufenberg GmbH- Silicone flat gaskets with low surface roughness

- Material can be produced in almost any desired thickness depending upon customer requirements

- Good compressibility

- Good positionality due to rigidity (quick assembly) & dimensional stability

Silicone Flat Gaskets for Fuel Cells

- Laufenberg’s silicone flat gasket with PET core was developed in years of cooperation with research institutes and customers especially for use in PEM fuel cells.

- Our goal was to be able to offer the growing fuel cell market high-quality gaskets efficiently and economically in the long term..

- With expert knowledge, state of the art machinery, high standards of service and quality and many years of experience provide Laufenberg with perfect prerequisites for coated fuel cell components business.

Key features

- Silicone sealing is available in customized thickness with a PET-core. The sealing is regular double side silicone coated but also as one side silicone coated version available.

- Good compressibility

- High tightness : Very even surface profile helps these gaskets provide a high gas and water tightness of the cell is already achieved with a low contact. This eliminates the need for additional gluing of the seal

- Low surface roughness

- Good positionality due to rigidity (quick assembly) & dimensional stability

- Material can be produced in almost any desired thickness depending upon customer requirements

- Thicknesses of 200 – 700 µm are commercially available

- Colors: Transparent (colored carriers on request)

- Core materials: PET (PEN, PP or others on request)

- Coating material: One or both sides

- Silicone: 100% solvent free, thermally curing silicone, tested for hydrogen application

- Widths: Up to to 550 mm

- Dimensions: Rolls or sheets, Laser/waterjet or die-cut on request (depending on quality)

- Form of deliveries: In general products can be delivered in formats (DIN A4) or in rolls in widths up to 550 mm.

Advantages in comparison to conventional silicone flat sealing’s

- The material is a hybrid of sealing silicone layers and a stiff foil as core. The given stiffness allows easy positioning and processing of the material. Because of our manufacturing process, the surface roughness of the sealing is very low. Due to the low roughness and the flat surface profile, the material already seals at low contact pressure. Bonding of the material is therefore usually not necessary.

Physical properties

- Typical Hardness IRHD, M (+/- 10 % in dependence on ISO 48)

- Chemical resistance:

- Cooling agent BASF Glysantin FC G 20-00/50 (72 hours, 85 °C)

- 0.1 M H2SO4 (48 hours, 80 °C)

Production process

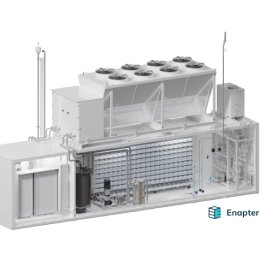

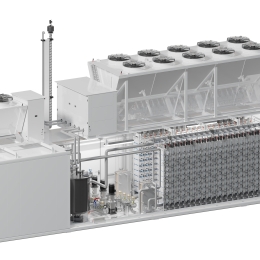

Applications

- For usage in PEM-fuel cells

- In electrolysers (test phase)

- For usage in heat exchangers

Contact us

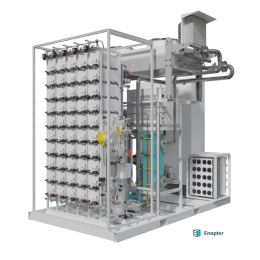

- The Laufenberg silicone flat gasket with reinforcing thermoplastic core is designed to be able to realise fuel cell and electrolyser stacking processes in a process-safe and stable as well as gas-tight manner. Interested? Please contact Laufenberg by filling in the contact request form.

| Brand | Laufenberg |

Laufenberg develops and produces catalyst coated membranes (CCM) and reinforced silicone flat gaskets for hydrogen applications. Laufenberg GmbH is a well-known coating company in the segment of release liners. In our business segment "Coated Fuel Cell Components" we offer customized and also standardized materials (primarily for use in PEM fuel cells) with our existing coating expertise. As components for the MEA assembly Laufenberg offers CCM's for automotive or heavy-duty applications. Besides one standard each, we focus on customer-oriented development and also develop CCM's for customer specific requests. In addition, our innovative reinforced silicone flat seal with PET core is already used in the market for stack assembly. Besides the standard PET-core, we can also use other carrier materials and adjust the layer thicknesses as well as other dimensions individually to customer requirements