Air Actuated Valves

Air Flow Control Valves

Angle Seat Valves

Ball Valves

Butterfly Valves

Cathode Isolation Valves

Check Valves

Coaxial Valves

Control Valves

Cryogenic Valves

Diaphragm Valves

Flow Control Valves

Globe Valves

Hydrogen Back Pressure Regulators

Hydrogen Filter Regulators

Hydrogen Fuel Cell Pressure Regulators

Hydrogen Pressure Reducing Valves

Hydrogen Pressure Relief Valves

Hydrogen Pressure Solenoid Valves

Hydrogen Tank Valves

Needle Valves

On Tank Valves

Plunger Valves

Process Automation Solenoid Valves

Proportional Valves

Safety Valves

Shut-Off Valves

Components

expand_more

Aftercoolers

Breakaways

Cell Voltage Monitors

Compressor Crankcase

Compressor Head

Converters

Couplings

Current Density Meters

Customised Plastic Parts

Diaphragms

Electrolyser Cells

Foils

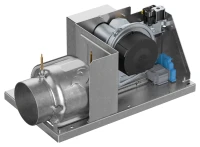

Fuel Cell Air Compressors

Fuel Cell Humidifiers

Fuel Cell Plates

Gas Handling Units

Gaskets

Hydrogen Burners

Hydrogen Fittings

Hydrogen Flow Controllers

Hydrogen Fueling Nozzles

Hydrogen Gas Boosters

Hydrogen Heaters

Hydrogen Hoses

Hydrogen Pumps

Hydrogen Refueling Data Interfaces

Hydrogen Tank Liners

Inverters

IoT Telemetry Device

Laminates & Coating

Laser Sources

Membrane Electrode Assembly

Pipes

Potentiostat

Power Electronics

Pressure Relief Devices

Receptacles

Seals

Thermocouples

Transducers

Tube Connections

Tubes

Valve Manifold

Valves

expand_more

Vents

Air Actuated Valves

Air Flow Control Valves

Angle Seat Valves

Ball Valves

Butterfly Valves

Cathode Isolation Valves

Check Valves

Coaxial Valves

Control Valves

Cryogenic Valves

Diaphragm Valves

Flow Control Valves

Globe Valves

Hydrogen Back Pressure Regulators

Hydrogen Filter Regulators

Hydrogen Fuel Cell Pressure Regulators

Hydrogen Pressure Reducing Valves

Hydrogen Pressure Relief Valves

Hydrogen Pressure Solenoid Valves

Hydrogen Tank Valves

Needle Valves

On Tank Valves

Plunger Valves

Process Automation Solenoid Valves

Proportional Valves

Safety Valves

Shut-Off Valves

Equipment

expand_more

Systems

expand_more

Automation Systems

Deoxygenation Systems

Fuel Cell Exhaust Air Systems

Fuel Cell Systems

Hydrogen Cooling Systems

Hydrogen Dispensers

Hydrogen Power Generators

Hydrogen Production Unit

Hydrogen Refueling Modules

Hydrogen Refueling Stations

Hydrogen Refueling Trailers

Hydrogen Storage Systems

Hydrogen Treatment Systems

Nitrogen Generators

Process Monitoring Systems

Remote I/O Systems

Reversible Fuel Cell Systems

Services

expand_more

by Country

expand_more

Brands

Albania

Algeria

Andorra

Argentina

Australia

Austria

Bahrain

Belarus

Belgium

Bolivia

Bosnia & Herzegovina

Brazil

Brunei

Bulgaria

Cameroon

Canada

Chile

China

Colombia

Costa Rica

Croatia

Cyprus

Czechia

Denmark

Ecuador

Egypt

Estonia

Finland

France

Georgia

Germany

Gibraltar

Greece

Grenada

Hong Kong SAR China

Hungary

Iceland

India

Indonesia

Ireland

Israel

Italy

Japan

Jordan

Kazakhstan

Latvia

Liechtenstein

Lithuania

Luxembourg

Madagascar

Malaysia

Malta

Mexico

Moldova

Monaco

Montenegro

Morocco

Namibia

Netherlands

New Zealand

Nicaragua

Nigeria

Norway

Oman

Pakistan

Panama

Paraguay

Peru

Philippines

Poland

Portugal

Puerto Rico

Qatar

Romania

Saudi Arabia

Serbia

Singapore

Slovakia

Slovenia

South Africa

South Korea

Spain

Sri Lanka

Sweden

Switzerland

Taiwan

Thailand

Tunisia

Türkiye

Ukraine

United Arab Emirates

United Kingdom

United States

Uruguay

Venezuela

Vietnam

Quick Coupler for 350 bar Systems - HC404

- Industry-leading flow rates.

- Anti-leak, spring-loaded poppets.

- All stainless steel construction ensures excellent corrosion and wear resistance.

- Hardened segment connection style increases gripping surface area, significantly reducing wear on male couplings.

- Designed for coupling/uncoupling only at atmospheric pressure.

- Green ring provides visual confirmation of proper connection.

- Service kits are readily available and easy to install.

Oasis Hydrogen ½” Quick Coupler for 350 bar systems

- The Oasis Quick Coupler is designed to deliver industry-leading flow rates and long-lasting performance in a variety of demanding hydrogen applications.

- Building on the success of the original Oasis design, this breakthrough product is ideal for 350-bar hydrogen applications, including high-flow virtual pipeline trailers .

- It complements a range of Oasis products, including ball valves, check valves, breakaways, cylinder valves, fill valves, and more.

- Male and female couplers are available individually if required.

- All products are manufactured to ISO 9001 standards and comply with PED 2014/68/EU regulations.

Key features

- Integrated lock-in-place sleeve ensures secure coupling.

- Green ring provides visual confirmation of correct connection.

- Anti-leak, spring-loaded poppets in both male and female sections.

- 316 stainless steel construction for durability.

- All components are hydrogen-compatible.

- Hardened segment connection style increases gripping surface area and significantly reduces wear.

- Designed for coupling/uncoupling only at atmospheric pressure (0 MPa gauge), preventing accidental disconnection.

- Fully field serviceable.

- Available in different configurations

- Operating Parameters:

- Maximum operating pressure: 450 bar (6,527 psi).

- Working temperatures: -40°C to 85°C (-40°F to 185°F).

Application areas

- Fast-flow filling systems.

- Storage cascade to hydrogen trailer.

- Trailer connection to daughter compressor.

- Hydrogen transportation.

- Flexible hose connectors.

Contact Us

- With a strong history of innovation and expertise in providing industry-leading fast-flow products, Oasis Engineering offers a comprehensive range of solutions for your hydrogen projects. Interested? Please fill in the Contact/RFQ form for more information.

| Brand | Oasis Engineering |

| Max Pressure (in bar) | 450 |

| Min Pressure (in bar) | 20 |

| Nom. Oper. Pressure (in bar) | 350 |

| Max Ambient Temperature (in °C) | 85 |

| Min Ambient Temperature (in °C) | -40 |

Oasis Engineering (2003) Ltd

Oasis Engineering Ltd. offers to deliver world-leading solutions to those pushing the boundaries of energy and fluid transfer for the benefit of the environment. Oasis's passionate and specialist teams work closely together to design, test and deliver a range of valves, couplings and refuelling nozzles used in over 40 countries.

Oasis Engineering is leveraging their experience in CNG to support the development of the Hydrogen industry, and are committed to adding value through customised solutions, short lead times, emphasis on high flow, and a reputation for excellent customer service.

Latest products

keyboard_arrow_left

keyboard_arrow_right