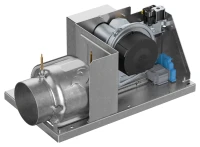

Plastic Ball Valves for Hydrogen Applications - 546 Pro

- Pneumatic or electric actuated low pressure valves for hydrogen applications

- Specific selection of plastic materials to avoid metal ion contamination of system.

- Suitable for operation in the temperature range up to 120°C and 16 bar.

- Light material plastic ball valves.

Plastic Ball Valves for Hydrogen applications

- Pneumatic or electric actuated low pressure valves for hydrogen applications

- Specific selection of plastic materials to avoid metal ion contamination of system

- Wide range of materials available

- Applications from a simple, manually operated shut-off valve to a fully automated ball valve

Key features

- Ergonomic lever, lockable as standard

- Quick label on request

- Integrated tool for the union bush

- Interface for flexible automation and accessories

- Reinforced security break point in the stem interface

- Double stem seals

- Dynamic backing seal

- Smooth spherical surface

- Sawtooth thread suitable for plastics

- Fastening system with integrated threaded bushes

- Data matrix code

- No metal ion leach-out

- Light material

- Corrosion free

- Chemical resistance

- Low CO2 footprint in comparison to metal

- Materials:

- PE

- PP

- PP-H

- PVC-C

- PVC-U

- PVDF

- Drive type:

- Electric

- Manual

- Pneumatic

Applications

- PEM electrolyser/ Water treatment, Cooling and Inlet

- AEM electrolyser/ Water Treatment, Header and Hook-up to stacks

- In approval for AEL electrolyser/ Water Treatment, media pipework

- PEM Fuel Cell stationary/ Cooling-, Hydrogen- & air Loop

- Marine methanol-powered fuel cell

Use cases

- Completely replacement of metal pipings in an Electrolyser (AEL, AEM, PEM)

- Completely replacement of metal pipings in an Fuel Cell (AEL, PEM)

- Water treatment plants

Contact us

- Georg Fischer ball valves meet every challenge and application, including simple water applications or complicated processes in the hydrogen industry. Interested? Please contact Georg Fischer by filling in the contact vendor form.

| Brand | Georg Fischer |

| Max Pressure (in bar) | 16 |

| Manufacturing Readiness (MRL) | 0 |

| Technology Readiness (TRL) | 0 |

| Max Ambient Temperature (in °C) | 120 |

Georg Fischer is proud of its long history of success with roots going back more than 200 years when Johann Conrad Fischer laid the foundation. What began in 1802 with a small copper smelting plant and development works for new alloys, has since developed in to the global industrial concern we know today. Today, it is established as a leading supplier of piping systems for the safe and reliable transport of liquids and gases. Despite the constant change, customer-centric innovation and sustainability remain the defining values for GF Piping Systems. GF Piping Systems aims to offer the right product portfolio for hydrogen production, storage, distribution and utilization including a tailor-made services package to support our customers so that they can focus on their competences. Our System's ELGEF Plus, MULTI/JOINT 3000 PLUS and PRIMOFIT are already certified for 100% hydrogen use by KIWA. ELGEF Plus and MULTI/JOINT 3000 PLUS are also certified as "H2 ready" for 100% hydrogen use by DBI. For more information on the piping system solutions along the entire value chain of production, storage, transportation/distribution, and utilization, visit: Hydrogen - GF Piping Systems (gfps.com)