Cathode Filter FT / FST - GMAC

Solberg Manufacturers Inc.- Special pleated cathode filter-elements with various layers and separating stages for the frictionless protection of your fuel cell system

- Standard and individual solutions available (please talk to us about your specific requirements)

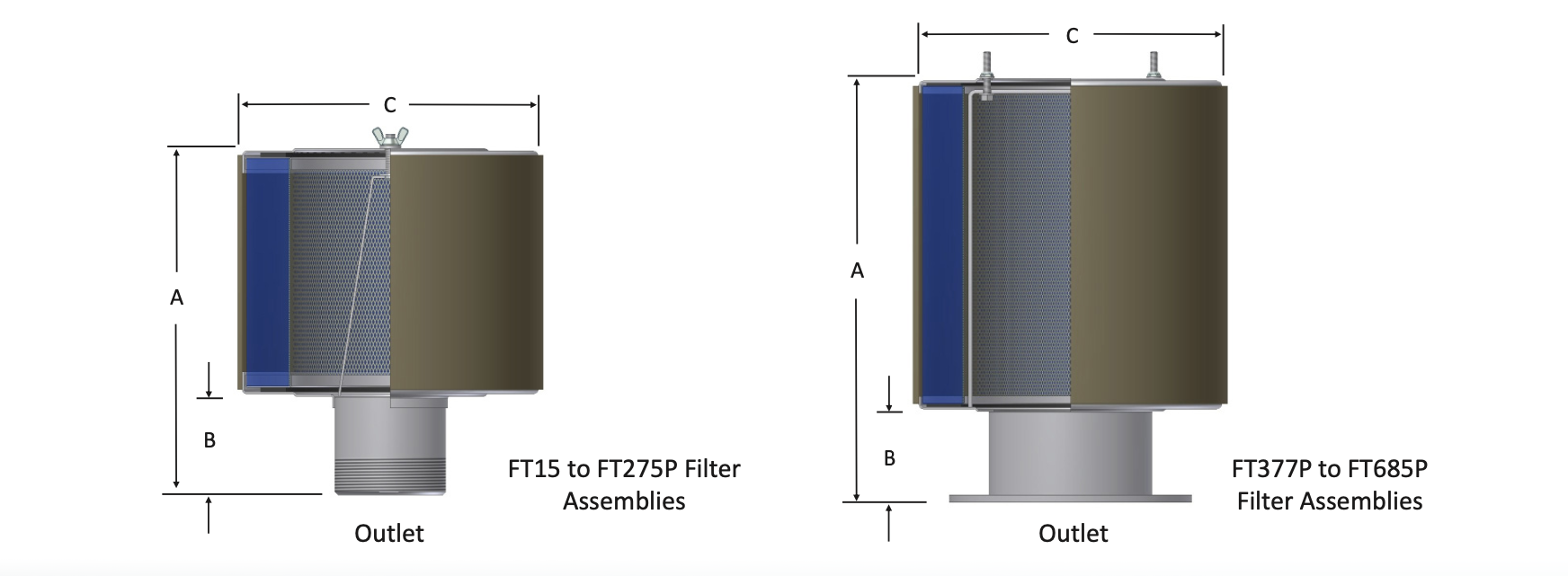

- Housings and filter-elements available in many different sizes and designs from Solberg

- Usable in the smallest installation space

- Easy sealing for good integration into the fuel cell system

Cathode Filter FT/FTS - GMAC

- Most common air contaminants present in operating environments are SO2 and NOx. Fuel cells are sensitive to these compounds as well as salts and VOCs which can enter the process via the intake air. Installation locations can be harsh, raising the importance for particulate removal. Maximizing air purity for the cathode is essential for optimizing a PEM fuel cell.

- Chemical adsorption is a process in which vapors and/or small particles are removed from the air or gas stream via filters containing adsorptive media. Contaminants are removed when they adhere to or react with the surface of the adsorbent media and allow the cleaned air or gas to pass through the filter.

- Maximizing the dwell time in which air or gas is in contact with the adsorbent media plays a key role in effective contaminant removal.

- Solberg evaluates each application and works within customer constraints and media adsorption capacities to optimize filter effectiveness.

Gray matter activated carbon (GMAC) as filter medium for fuel cells

- Solberg’s special GMAC filter element, a chemical vapor adsorption element, which is especially developed for the protection of the fuel cell’s cathode.

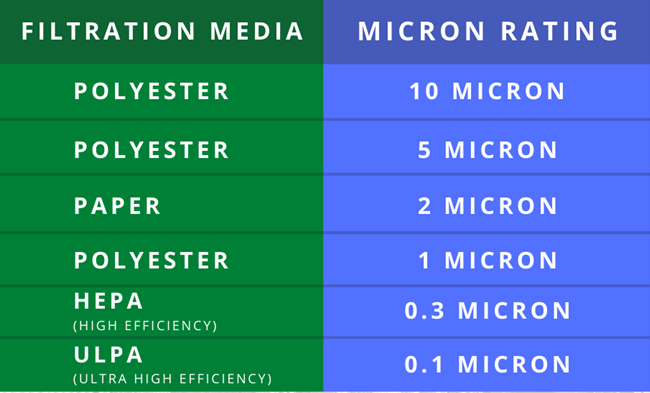

- GMACZ: 1 micron, 99+% efficiency

- Optional filter medias are available, some can be combined with our GMAC-elements. Please contact us for specific information.

Key Benefits

- Standard and individual solutions available: we partner with you to find the perfect filtration solution for your specific application

- Large flow range available: 5m³/h – 14000m³/h

- Development and production in the USA: We have the control over our processes, development, and construction, which ensures the highest quality of our products

- Various layers provide the perfect absorption of particles, liquids, and harmful gases due to different separation-stages

- Pressure drops typically less than 6 mbar – pressure drop curves available upon request

Features

- Support material made of galvanized metal

- Minimal waste due to compact design

- Optimize surface area to offer low pressure drops and long filterlife

- ISO11155-2 (previously DIN 71460) - tested

- Easy installation

A variety of filter media and assembly options are available

- You can find the different media specifications in our technical data sheets for US and for RoW

- You can find the different exposed inlet filters of FT series here: FT Series 1/2” - 6”, DN80 - DN300 or FT Series 1/2” - 14”

- Please visit the download section for further information.

Application areas

- Mobile or stationary fuel cell applications

Cathode Protection Illustration

Recent projects

- Solberg already gained a lot of experience by helping some important players in the fuel cell industry to develop suitable filtration solutions for their systems. These applications have been in a wide range, using our filtration solutions in small and big systems, as well as in stationary and mobile fuel cell solutions.

Working with Solberg

- With more than 50 years of experience in the development and production of filtration solutions, the name SOLBERG stands for expertise in filtration like no other. By taking particles, liquids, steam, oil mist and harmful gases out of the air stream, we protect all kind of machines and at the same time the environment.

- We want to help our partners to innovate, to find new ways and solutions to enhance their technologies and make power generation more sustainable. For this reason, Solberg developed specific filtration solutions for fuel cells, which we think, will be an important part in the futures energy storage market.

Contact us

- Contact our team today. We’re happy to help you find the right filter solution that best suits your application’s requirements.

| Brand | Solberg |

| Manufacturing Readiness (MRL) | 0 |

| Technology Readiness (TRL) | 0 |

With more than 50 years of experience in the development and production of filtration solutions, the name SOLBERG stands for expertise in filtration like no other. By taking particles, liquids, steam, oil mist and harmful gases out of the air stream, we protect all kind of machines and at the same time the environment. We want to help our partners to innovate, to find new ways and solutions to enhance their technologies and make power generation more sustainable. For this reason, Solberg developed specific filtration solutions for fuel cells, which we think, will be an important part in the futures energy storage market. Please feel free to contact us for your individual application, that we can find the best solution for your problem together.