- Why is reliable measurement technology essential for hydrogen applications?

- What chemical properties of hydrogen make accurate measurement difficult?

- What physical properties of hydrogen create challenges for instrumentation?

- How is hydrogen produced, and where is measurement technology used?

- How is hydrogen transported, and what measurement challenges are involved?

- How is hydrogen stored, and what measurement requirements are involved?

- What are the key requirements for pressure and level measurement in hydrogen systems?

- What measurement technologies are commonly used for hydrogen applications?

- How does digitalization improve hydrogen process safety and performance?

Why is reliable measurement technology essential for hydrogen applications?

Reliable measurement is the backbone of safe and efficient hydrogen handling. Because hydrogen can behave unpredictably under changing temperature and pressure conditions, precise monitoring of pressure, level, flow, and system integrity is indispensable. Small deviations can lead to leaks, loss of product, inefficiencies, or safety hazards. As hydrogen infrastructure expands and operating conditions become more complex, accurate instrumentation becomes a key enabler for scaling the hydrogen value chain.

What chemical properties of hydrogen make accurate measurement difficult?

Hydrogen is the smallest and lightest element, and this simplicity gives rise to several challenging chemical properties. Its high reactivity means that only a tiny ignition energy is required to trigger combustion, which greatly increases the safety requirements for any measurement device. A more subtle challenge is hydrogen embrittlement, where hydrogen molecules diffuse into metals, weaken their structure, and may cause cracks or sudden failure. This effect intensifies at high pressures and must be considered in material selection, sensor housing, and long-term instrument performance.

What physical properties of hydrogen create challenges for instrumentation?

Hydrogen’s physical characteristics place exceptional demands on measuring equipment:

- Extremely low density: At 0.0899 kg/m³ under standard conditions, hydrogen is the lightest known gas.

- Large volume per unit of energy: This means hydrogen must be compressed up to ~700 bar or liquefied at -253 °C for efficient storage or transport.

- High diffusivity: Hydrogen atoms penetrate materials easily, contributing to leakage and measurement drift.

- Extreme temperatures and pressures: Instruments must withstand rapid fluctuations and long-term exposure to high-stress conditions.

These conditions require materials, seals, and sensor designs capable of maintaining accuracy under cryogenic temperatures, extreme pressures, and constant exposure to diffusion effects.

How is hydrogen produced, and where is measurement technology used?

Hydrogen is produced through a range of methods, from traditional fossil-based steam reforming to increasingly widespread low-emission electrolysis systems. Each of these routes relies on measurement technology to maintain stable, efficient operation. In steam reforming, pressure and temperature control are essential to manage high-temperature chemical reactions. In electrolysis systems; whether alkaline, PEM, or high-temperature, monitoring electrolyte levels, hydrogen and oxygen pressures, and internal cell conditions is crucial for operational efficiency and equipment safety. Across all production methods, measurement instruments help ensure consistent product quality, plant reliability, and process safety.

How is hydrogen transported, and what measurement challenges are involved?

Hydrogen transportation depends heavily on volume, distance, and intended use. Each method has unique Instrumentation needs.

Transport methods:

- Compressed gas transport (up to 700 bar or higher) – common for smaller volumes, typically by road

- Liquefied hydrogen transport – enables larger volumes but requires temperatures below -253 °C

- Hydrogen carriers such as ammonia, methanol, or LOHCs – easier to transport using existing fuel infrastructure

- Pipelines – the most economical method for long distances up to ~10,000 km

Measurement Challenges:

- Maintaining accurate readings under ultra-high pressures

- Preventing failures caused by hydrogen embrittlement

- Ensuring leak detection in highly diffusive environments

- Managing cryogenic conditions during liquefaction and regasification

Instrumentation must remain stable despite extreme temperature swings, varying flow rates, and pressure cycling.

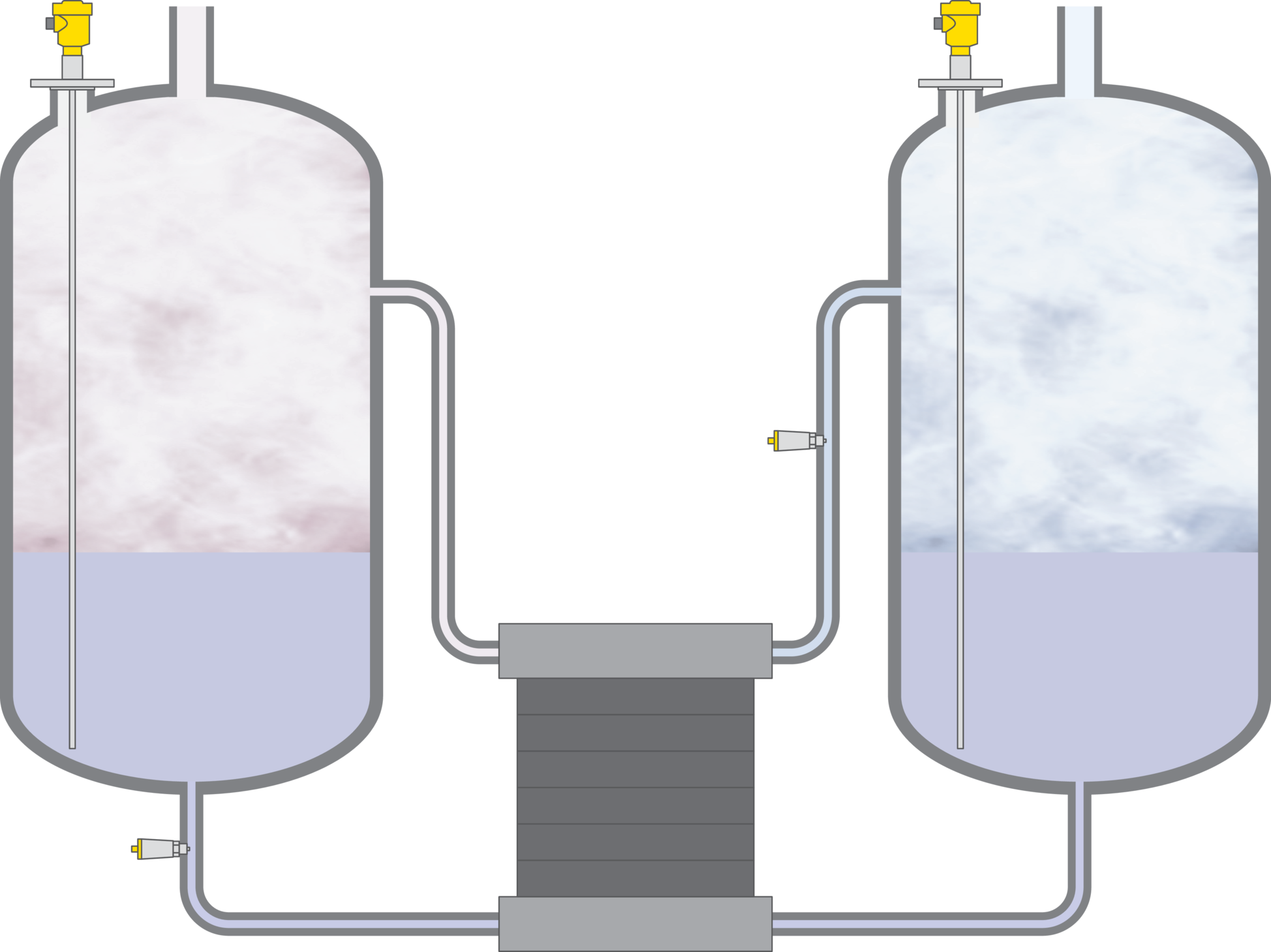

How is hydrogen stored, and what measurement requirements are involved?

Hydrogen storage depends heavily on the application. Pressurized gas storage is widely used and demands precise pressure monitoring to prevent overfilling or structural overload. Cryogenic storage requires both pressure and level measurement solutions that can operate in conditions where boil-off, temperature gradients, and thermal contraction must be managed. In cases where hydrogen is stored chemically, such as in ammonia or methanol, the measurement instruments must be compatible with the fluid properties and able to operate reliably during the conversion and reconversion processes. Accurate measurement at all storage points is central to system efficiency and safety.

What are the key requirements for pressure and level measurement in hydrogen systems?

Although hydrogen applications vary widely, certain instrument characteristics are universally important:

- Long-term resistance to hydrogen diffusion

- Stability at extreme pressures or cryogenic temperatures

- Materials that resist embrittlement

- Capability to measure media with very low dielectric constants

- Fast response to dynamic process conditions

- Compliance with safety standards such as explosion protection and functional safety

These requirements ensure that the measurement system can withstand harsh environments while maintaining accuracy over the system’s life cycle.

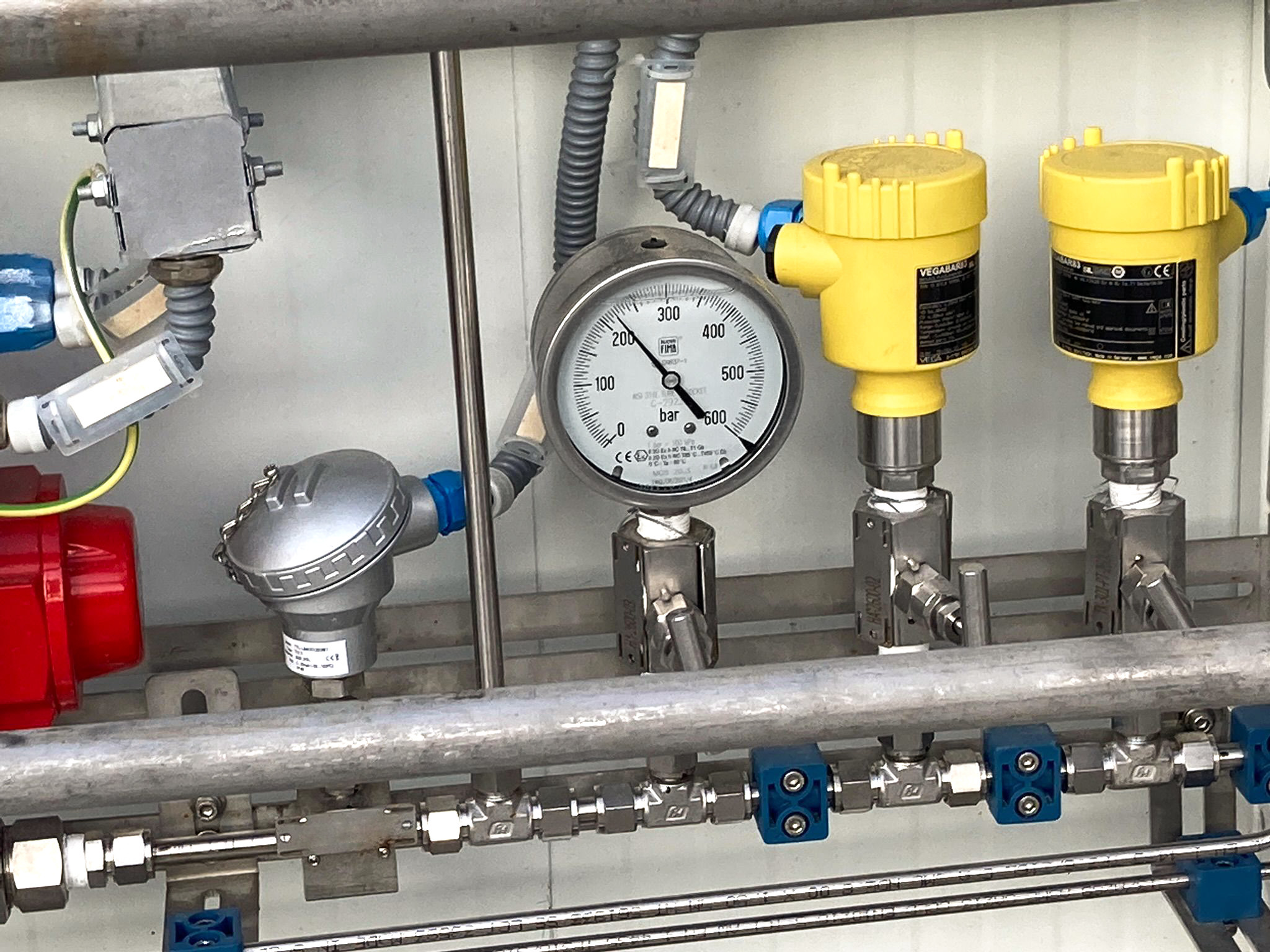

What measurement technologies are commonly used for hydrogen applications?

Hydrogen measurement typically relies on technologies that are inherently resistant to hydrogen diffusion and capable of functioning under harsh operating conditions. Ceramic pressure cells are widely used for gaseous hydrogen because they do not require transmission oils and maintain stability over long periods. Metallic pressure cells are often selected for extremely high-pressure applications, and these may incorporate protective coatings to reduce diffusion effects. For level measurement, radar-based technologies; both free-radiating and guided-wave, are commonly deployed because they provide reliable results even when the medium has a low dielectric constant or is subject to temperature fluctuations.

How does digitalization improve hydrogen process safety and performance?

Digital features have become increasingly important across the hydrogen sector. Many modern instruments offer self-diagnosis capabilities that detect irregularities before they escalate into failures. Digital communication protocols enable integration with advanced control systems and allow real-time monitoring of key process variables. This level of insight can prevent downtime, improve maintenance planning, and enhance overall system efficiency. Digital tools also support traceability and provide operators with the data needed to optimize hydrogen production, transport, and storage systems.

Content contributed by VEGA Grieshaber KG

Level and Pressure Measurement Technology from VEGA for safe hydrogen applications.. Whether electrolyzer, pipeline or filling station – hydrogen processes place the highest demands. As one of the world’s leading providers of Level and Pressure Sensors, VEGA delivers customized solutions for this purpose. The Level Sensors impress with the highest measurement accuracy even under extreme conditions and provide a transparent overview of storage and process at all times. Pressure Sensors with metallic or ceramic measuring cells and diffusion-tight connections capture stable, precise values. Supplemented by stainless steel 316L and special coatings, hydrogen embrittlement is reliably prevented. This is how VEGA creates the basis for reliable hydrogen processes that combine highest safety with sustainable efficiency.

Digitalization for more efficiency: Even in the hydrogen sector, future-proof data exchange determines competitiveness. With standardized interfaces and the implementation of digital twins, VEGA solutions enable a precise analysis of process data. In addition, our Sensors meet international safety standards such as ATEX, IECEx and offer a layered security concept for improving cybersecurity with IEC 62443-4-2.

Partnership for optimal applications: With VEGA as your partner, you benefit not only from the highest quality of measurement technology. Our 2,600 employees in more than 85 countries are at your side with a comprehensive range of services. From the first product idea through development and production to collaborative consulting, we offer customized solutions for your hydrogen applications.