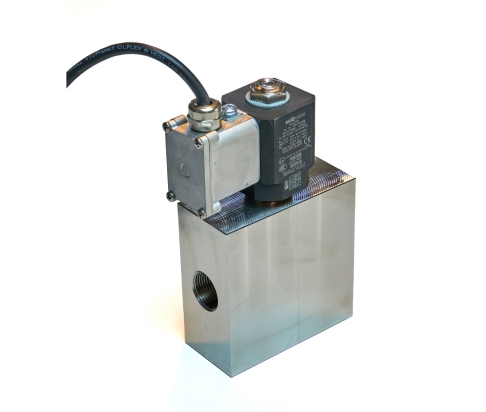

Hydrogen High Pressure Solenoid Valve – Type 3109 A-1 – H35

Eugen Seitz AG- Hydrogen high pressure solenoid valve – type 3109 – H35 has smallest footprint, no air required

- Suitable for heavy-duty, fast fueling ready

- Tubing size 1"

- Best-in-class temperature range: -40°C to +85°C

- Highest reliability: Lifetime >500,000 cycles

- CE-sign refers to PED 2014/68/EU

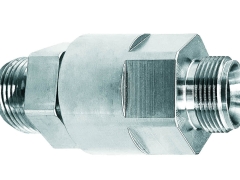

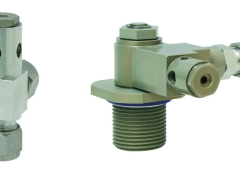

Hydrogen high pressure solenoid valve – type 3109 A-1 – H35

- The largest orifice size currently available on the high-pressure hydrogen solenoid valve market.

- Hence, the HyValve 500 DN 15 guarantees an enormous flow rate to speed up every refueling process of current and future refueling protocols

- Ideal for heavy-duty vehicles, trucks and busses.

- Despite the large orifice, its compact design still assures neat installment within the refueling system.

- Due to Seitz' high quality and safety requirements, reliable and continuous use within the full temperature and pressure range is possible.

- Hydrogen solenoid shut-off valve, piloted with own fluid

- Every valve tested at 100% with hydrogen gas mixture

- All wetted materials fully hydrogen compatible, no hydrogen embrittlement

- High-performance dynamic seals for lowest leakage and long service life

Key features

- Tubing size 1'

- Connection: MP Cone & Thread

- Kv 3.88 m3/h | Cv 4.486 US-gal/min

- Pressure range up to 500 bar

- Lifetime 500'000 cycles

- Rated voltage 24V AC/DC or 230V AC

- Rated Power 16W

- IP-Code 65/67

Benefits

- Ease of mind in refueling

- Largest orifice size currently available on the high-pressure hydrogen solenoid valve market

- Low refueling time required

- Energy efficiency: Low pressure drop through valve

- Long service interval for lowest TCO

- Highest availability due to broad temperature range

Solenoid coil 2F86: Approvals

- EPS 18 ATEX 1098 X

- IECEx EPS 18.0055 X

- NEPSI GYJ 18.1429 X

- Ex II 2G Ex mb IIC 150°C(T3)…(T4*) Gb (* T4 : up to +65°C ambient)

Application areas

- Suited for all high-pressure hydrogen applications

- HRS: Cascade storage valve/priority panels and dispensers

- Trailer and mobile refueling

- Medium pressure fluid handling systems

- Test applications

Project cases

- Hydrogen refueling stations (HRS), HyValves are used for managing hydrogen gas flow in and between storage banks (cascade), cryo-pump, compressor and dispenser.

- The highest-capacity and fastest-flow refueling stations in the world rely on HyValve performance.

- HyValves are actively operating in refueling stations in USA, Europe, China and more countries.

- HyValves are also used as shut-off valves upstream of hydrogen pressure regulators, to enable the downstream pressure regulator to remain gas-tight.

Contact us

- Contact us and tell us about your requirements. We will identify the products that provide the performance you expect.

| Brand | Eugen Seitz |

| Max Pressure (in bar) | 500 |

| Min Pressure (in bar) | 10 |

| Max Power (in kW) | 0.016 |

| Ingress Protection Rating | IP65, IP67 |

| Manufacturing Readiness (MRL) | 0 |

| Technology Readiness (TRL) | 0 |

| Max Ambient Temperature (in °C) | 85 |

| Min Ambient Temperature (in °C) | -40 |

SeitzValve is an independent, family-owned company with more than 60 years of experience. The core business of Eugen Seitz AG is solenoid valve technology for technically demanding applications. We develop solutions for gaseous media at medium to high pressure (16 to 1,000 bar). We are fully vertically integrated: All our products are developed, produced, packaged, and shipped from our head office in Switzerland in Wetzikon near Zurich. Our competitive offering is enabled by a high degree of automation – production runs 24/7 and with minimal manual input. Our industry-leading valves for hydrogen refueling station (HRS) applications enable ease of mind in refueling. We support H35 and H70 architectures with maximum fueling performance at low power, exceptional temperatures and with a minimal footprint. All valves are supplied with operating instructions and CoC (CE/PED, IECEx, ATEX, Nepsi, CCC and more). Availability and reliability are key differentiators of all Seitz valves. Every hydrogen valve is fully tested on an automated test bench for function and leakage with hydrogen forming gas. With our deep application engineering knowledge, we can integrate our premium solenoid valves in system modules, tailored to our customers' needs. The SeitzValve team is ready for your challenges. Do not hesitate to contact us, we are happy to help you build a hydrogen economy.