Anti Vibration Collet Gland Assemblies

Maximator GmbH- The 1,550 bar series medium pressure anti-vibrational collet gland assemblies are designed for simple and safe connection of hydrogen pipes up to a maximum pressure of 1,550 bar.

- All gland assemblies are fit for multiple use. Fittings are supplied complete with collars and glands.

- The operating temperature range is -50 °C to +350 °C

Anti vibration collet gland assemblies

- Maximator anti-vibration collet gland assemblies are for use in applications where there could be extreme external mechanical vibrations or shock in tubing lines.

- These collet gland assemblies are interchangeable with the standard medium pressure coned and threaded tube connections.

- In a normal coned and threaded tube connection, any external mechanical loading on the tubing lines, valves or fittings would be concentrated on the first thread of the tube. This can cause failure of the tube at this thinner cross-section.

- The anti-vibration collet gland assembly grips the tube behind the connection, supporting the tube at the full cross-section and straight area, moving the loading away from the threaded area.

- The back part of the assembly has a gland nut that, when tightened properly, compresses a split collet on the tube, providing the beneficial gripping action.

- All anti-vibration collet gland assemblies come with a Molybdenum Disulfide Coating to guard against galling of the stainless components.

Key features

- Good resistance against extreme vibrations

- Compatible with standards available

- Pressure range up to 1550 bar

- Temperature range of -50 °C to 350 °C

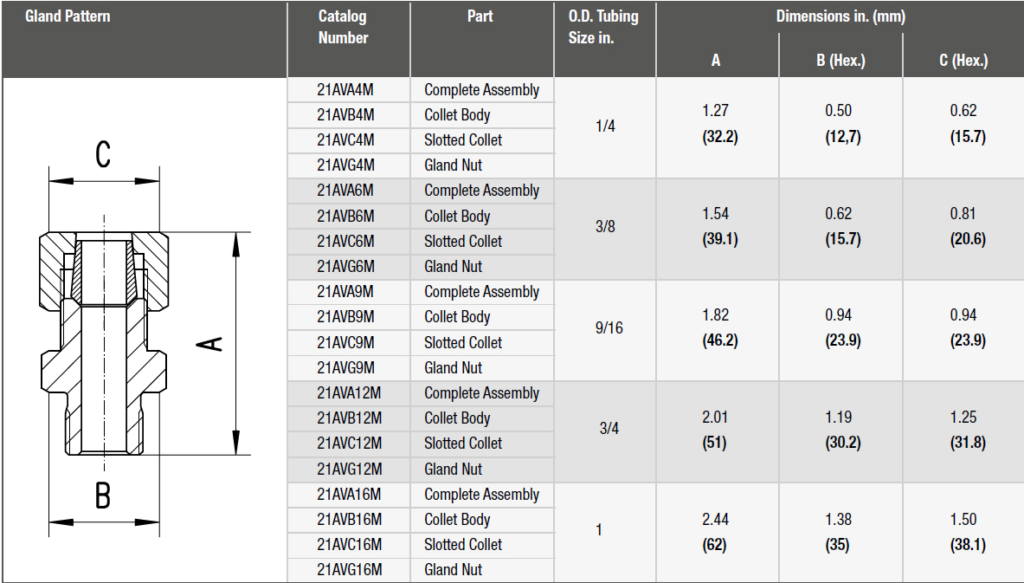

Gland pattern

Application

- General hydrogen use

- Medium pressure panels

- Medium pressure fluid handling systems

- Testing application

Contact us

- Maximator can provide technical drawings upon request. Contact us and tell us about your requirements. We will identify the products that provide the performance and safety you expect.

| Brand | Maximator |

| Max Pressure (in bar) | 1550 |

| Manufacturing Readiness (MRL) | 0 |

| Technology Readiness (TRL) | 0 |

| Max Ambient Temperature (in °C) | 350 |

As an internationally leading company specialized in high-pressure technology, Maximator develops high-performance products and solutions for a variety of uses and applications in the field of high pressure testing and production equipment, hydraulics and pneumatics. Maximator has many years of experience with components, power units and test systems especially for hydrogen applications Many components for the development of this future technology are exposed to extreme stresses. Maximator meets this challenge with innovative high pressure test technology for hydrogen components such as valves, pipes or CGH vessels. We can carry out all legally prescribed testing on pressure bearing components with our test technology: from individual acceptance to type approval testing. We also offer gas control technology for hydrogen applications - approved effective and reliable technology for automotive manufacturers and suppliers.