Multilevel Highspeed Inverter MLI 30

- Multilevel Highspeed Inverter MLI 30 has DC supply voltage up to 800 V DC

- Our inverter was developed for fuel cell air compressors and electric turbochargers

- Nominal phase current up to 30 ARMS

- Stator frequency up to 3,000 Hz

- PWM switching frequency up to 50kHz

Multilevel Highspeed Inverter MLI 30 descriptions

- Turbo speed and system costs under control. Our multi-level technology enables us to keep very high motor and generator speeds of up to 180,000 rpm safely under control.

- The control technique and high PWM frequencies reached result in considerably lower rotor losses in the electrical machine, thus leading to a significant reduction in system costs.

- Multilevel Highspeed Inverter family undergoes double inspection in the production.

Key features

- Field-proven sensorless speed and torque control

- Liquid-cooled, inlet temperature <70°C (under full load conditions)

- CAN interface

- IP67 enclosure

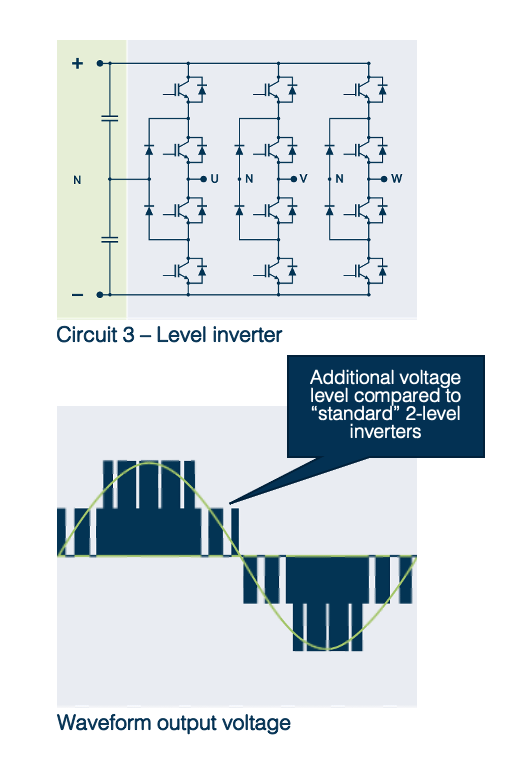

MLI Technology

- Drivetek has been applying multilevel technology to high-speed inverters (MLI) for e-motors spinning up to 180'000rpm since 2012. MLIs are used for air compressors, electric turbochargers and heat recovery applications

- MLI technology provide cost advantage using standard IGBTs

- Through the high PWM frequency and additional voltage level, lower pulsations of the magnetic field can be achieved, this leads to significantly lower rotor losses (eddy currents)

- Due to the series connection of the switches, the voltage on each switch is only half of the DC Link voltage (e.g. 900V DC Link can be realized using a 600V class IGBT)

- Multilevel technology allows significantly more complex control and error handling than 2-level architectures such: a) additional degrees of freedom, b) avoid 'dangerous' power-off states in case of errors and c) control of the 'N' point

- To date, Drivetek has delivered several thousand units for a wide range of mobile fuel cell applications worldwide.

- Drivetek has implemented all the tools to safely control multilevel inverters.

- Drivetek's proprietary QUASAR SW platform and Q-Control SW allow more than 300 parameters to be managed freely.

Application areas

- MLI is developed for fuel cell air compressors and electric turbochargers

- Cars

- Industries

- Electrical Grid connection

- Aviation

We include state of art testing in our production processes

- Incoming inspection

- Automated PCB function testing, more than 100 tests, 100% test coverage

- Thermal burn-in test

- SW Programming

- EOL test

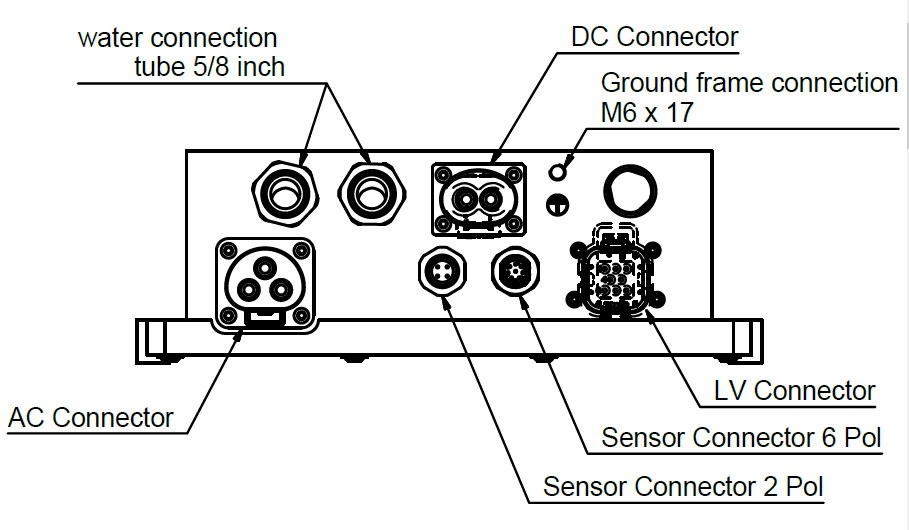

Electrical interfaces

Contact us!

By pooling our experience, knowledge and technology, we are able to meet your requirements with precision.

Your request is our challenge! In 2002 we entered the marked as a start-up. Since then, we have gradually picked up speed and today employ more than 50 technology-obsessed members of staff. They are responsible for shaping our company and making it as strong as we are: they combine passion for their work with absolute precision. They reconcile experience with a willingness to think outside the box. They are experts in their field and concentrate first and foremost on delivering the highest possible quality. Drivetek's comprehensive systems expertise in electric drive technology and power electronics is based on our specialist knowledge of electrical machines with related inverters/DC-DC converters, including the associated software, along with the courage to change perspective.