Hydrogen Piston Compressor MAX Compression 2.0

- Unique and globally patented Automatic Seal Exchange (ASX) seal change technology.

- Reduced operating and maintenance costs due to ASX.

- Highly-efficient compressor with up to four times the performance.

- Enhanced quite operation also at significantly higher frequencies.

- MAX Compression 2.0 revolver loader contains 20 interchangeable seals.

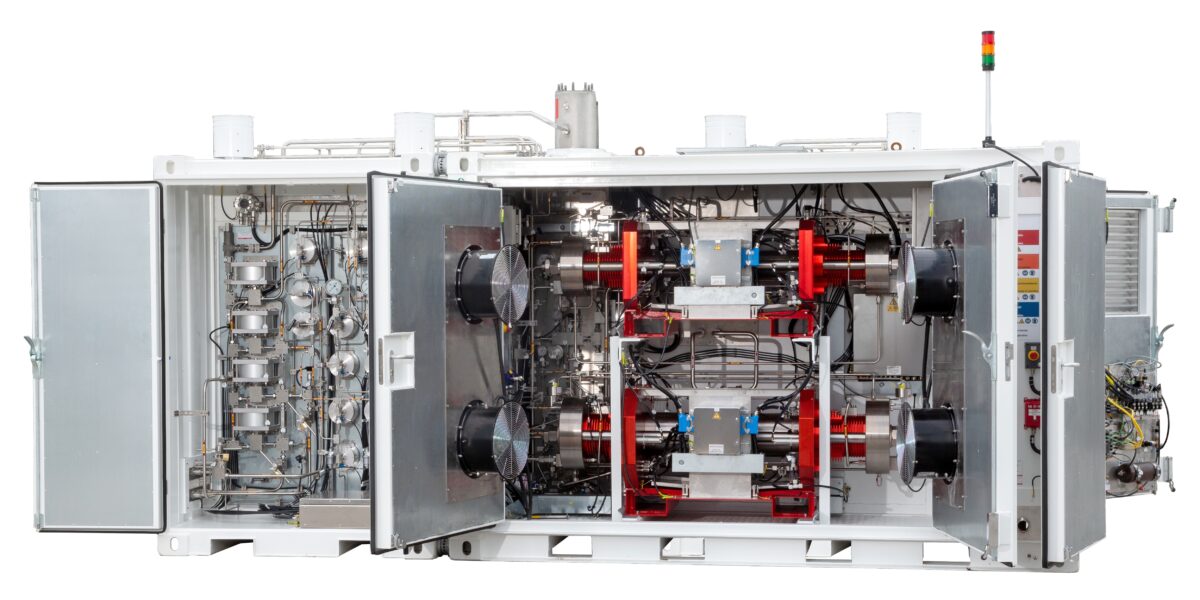

Hydrogen piston compressor MAX Compression 2.0

- The MAX Compression forms the heart of the Maximator Hydrogen refueling stations and ensures the compression of the hydrogen.

- MAX Compression 2.0 is a highly-efficient compressor which works with the same installation space and optimized energy requirements with up to four times the performance compared to other piston compressors.

- With the new MAX Compression 2.0, the hydrogen for use in fuel cells or combustion engines can be compressed directly to high pressure during refueling and without the intermediate storage that has been the norm until now.

- This is made possible by the exchangeable drive units.

- In addition to a need-based adjustment of the compression capacity, these also allow operators a cost-effective entry into hydrogen technology.

- In addition, by expanding the drive units, the performance of a hydrogen filling station can be increased fourfold, so that heavy-duty on- and offroad hydrogen filling as well as ship and train filling stations can be efficiently implemented with this technology.

- Due to the arrangement of the hydraulic pistons and the precise digital synchronization, the new solution not only works more quietly, but also with significantly higher frequencies.

- The process control also ensures that the piston movement utilizes the maximum compression space.

- MAX Compression 2.0 is also equipped with the unique and globally patented Automatic Seal Exchange (ASX) seal change technology.

- With this, the regularly required replacement of the piston seals in the refueling system, which are subject to increased wear due to contact with hydrogen, takes place automatically and within a few minutes.

- Unwanted downtimes and cost-intensive replacement processes within the hydrogen filling station are therefore reduced to an industry-wide minimum.

- The ASX function has also been further developed and optimized for the new compressor generation MAX Compression 2.0.

- The revolver loader from compressor system versions 1.0 and 1.5, with which 4 seals can be automatically exchanged within a truly short service life, was expanded on the basis of a bar magazine for up to 20 interchangeable seals.

- When performing the automatic seal exchange, several position sensors in combination with a pneumatic motor control the process combination with a pneumatic motor control the process of rotation of the turret plate that holds the seal cartridges.

- The automatic changeover times for a seal have also been reduced to 15 seconds.

- The high-pressure compressor is based on a two-stage compression system with an intercooler, which enables a safe and pollution-free compression process.

- MAX Compression Stage 1 compresses the hydrogen up to 250 bar, depending on the inlet pressure.

- MAX Compression Stage 2 compresses the hydrogen up to 910 bar.

- The Max Compression 2.0 was developed in close cooperation with Bosch Rexroth, development partner and system supplier for the energy-efficient drive of the compressor, and with Maximator Advanced Technology (MAT) from Vienna.

Key features

- Highly-efficient compressor that works with the same installation space and optimized energy requirements with up to four times the performance.

- Hydrogen compression without intermediate storage.

- Exchangeable drive units.

- Enhanced quite operation.

- Can operate with significantly higher frequencies.

- Unique and globally patented Automatic Seal Exchange (ASX) seal change technology.

- With the Automatic Seal Exchange, the seal in the refueling system is changed fully automatically and within a few minutes.

- This reduces undesired downtimes of the hydrogen filling station to an industry-wide minimum.

- Also, ensures a high level of operational availability and cuts service costs enormously.

- MAX Compression 2.0 revolver loader contains 20 interchangeable seals.

- Automatic changeover times for a seal reduced to 15 seconds.

- Max Compression 2.0 was developed in close cooperation with Bosch Rexroth and with Maximator Advanced Technology (MAT).

Application areas

- Hydrogen refuelling stations

Contact us

- Maximator Hydrogen offers highly reliable and modern hydrogen filling stations from a single source. Interested? Please fill out the contact vendor form to contact the vendor.

| Brand | Maximator Hydrogen |

| Compressor Type | Reciprocating |

Maximator Hydrogen GmbH from Nordhausen is a leading supplier and developer of comprehensive system solutions for the entire value chain of hydrogen technologies. With over 200 employees, the company combines unique expertise with the know-how of approximately 700 H2-relevant patents. As a fast and efficient partner for the planning, construction and operation of hydrogen infrastructures for road, rail and marine transport, Maximator Hydrogen, a company of the Schmidt Kranz Group, offers highly reliable and modern hydrogen refueling stations from a single source. With its high performance, flexibility and speed, Maximator Hydrogen is a central partner for specifically tailored hydrogen solutions for large international companies and corporations.