Hydrogen Compression System X-Tower

- Revolutionary compression technology

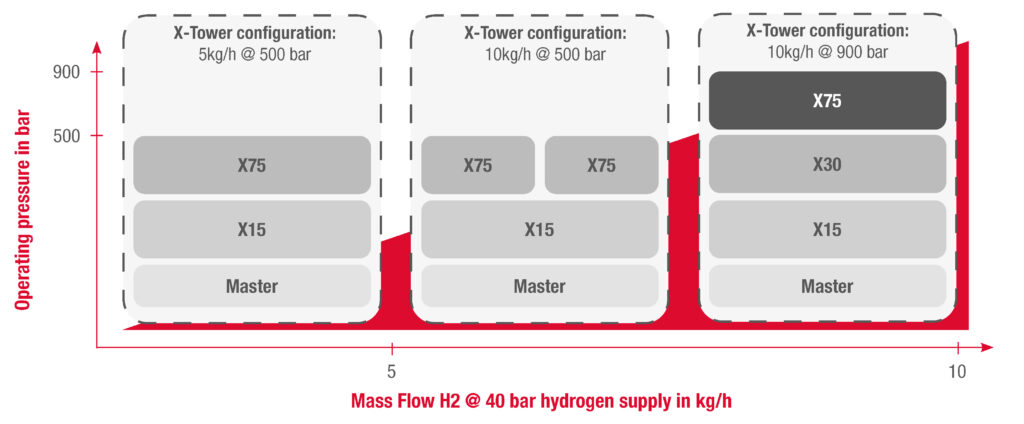

- Hydrogen mass flow up to 10 kg/h ++ 900 bar

- Hydrogen compression system is designed for maximum efficiency

- Plug&boost design for integrator

- Flexible and modular system design

Hydrogen compression system X-Tower

- The Maximator X-TOWER is a modular hydrogen compression system, specifically designed for hydrogen compression up to 300 bar with scalable volume flow. The X-TOWER is designed for integration in existing systems and is covering nearly all requirement for efficient gas compression.

- A standard configuration up to 900 bar consists of one MASTER-Module (control module) and up to three X-Modules (gas booster modules) - first stage module up to 300 bar, second stage module up to 600 bar and the final stage module up to 900 bar. This configuration will provide a gas outlet flow of 10 kg hydrogen per hour (average flow for filling application higher).

- The gas compression is realized with our new EHB-Series booster technology (Electro-Hydraulic-Booster) and provides unrevealed efficiency due to their completely redesigned electrohydraulic drive concept.

- For all applications the MASTER module is mandatory and is handling safety and functional features for maximum three X-Modules. The X-Modules can be combined and connected depending on the application.

Key features

- Flexibility: With the hydrogen compression system X-TOWER you are planning the future. Our solution can be adapted to new challenges by changing, adding or removing X-Modules. The modular design of hydrogen filling station allows countless combinations of X-Modules to cover many different applications and requirements.

- Efficiency: With the new frequency converter controlled complete closed hydraulic drive concept of our EHB-Series we are providing the most efficient way to compress gases.

- Efficient hydraulic drive with less oil volume

- Direct separation between process gas and hydraulic

- Flushing concept integrated

- Quite drive technology

- Cooling: Intelligent and efficient new cooling concept keep the gas temperature under control with minimum energy consumption.

- Safety: Purging, temperature & pressure control, gas detection, active ventilation are only some of our safety features of the new X-Tower series.

- Integration: „Plug & boost“. A web based access to the control system offers independent control with your mobile PC or smartphone. The hydrogen compression system X-Tower series is prepared for IoT integration to improve processes and provide more information about the compression process than ever before.

- Smart automated pressure generation

- More flexibility than ever before

- Innovative maintenance concept

- Safe and clean hydrogen compression

Our X-Tower system provides a modular approach

Application areas

- Hydrogen pressure generation up to 900 bar

- Laboratories

- Universities

- Research & development

- Calibration product acceptance test

- Small & medium scale refueling application

- Hydrogen gas transfer

- Hydrogen recovery

- Compression after electrolyzing

- Workshop or test field area

Contact us

- Contact us and tell us about your requirements. We will provide the product with performance and safety you expect.

| Brand | Maximator |

| Type of Cooling | Liquid Cooled |

| Max Pressure (in bar) | 900 |

| Max Mass Flow (in g/s) | 2.78 |

As an internationally leading company specialized in high-pressure technology, Maximator develops high-performance products and solutions for a variety of uses and applications in the field of high pressure testing and production equipment, hydraulics and pneumatics. Maximator has many years of experience with components, power units and test systems especially for hydrogen applications Many components for the development of this future technology are exposed to extreme stresses. Maximator meets this challenge with innovative high pressure test technology for hydrogen components such as valves, pipes or CGH vessels. We can carry out all legally prescribed testing on pressure bearing components with our test technology: from individual acceptance to type approval testing. We also offer gas control technology for hydrogen applications - approved effective and reliable technology for automotive manufacturers and suppliers.