Air Actuated Valves

Air Flow Control Valves

Angle Seat Valves

Ball Valves

Butterfly Valves

Cathode Isolation Valves

Check Valves

Coaxial Valves

Control Valves

Cryogenic Valves

Diaphragm Valves

Flow Control Valves

Globe Valves

Hydrogen Back Pressure Regulators

Hydrogen Filter Regulators

Hydrogen Fuel Cell Pressure Regulators

Hydrogen Pressure Reducing Valves

Hydrogen Pressure Relief Valves

Hydrogen Pressure Solenoid Valves

Hydrogen Tank Valves

Needle Valves

On Tank Valves

Plunger Valves

Process Automation Solenoid Valves

Proportional Valves

Safety Valves

Shut-Off Valves

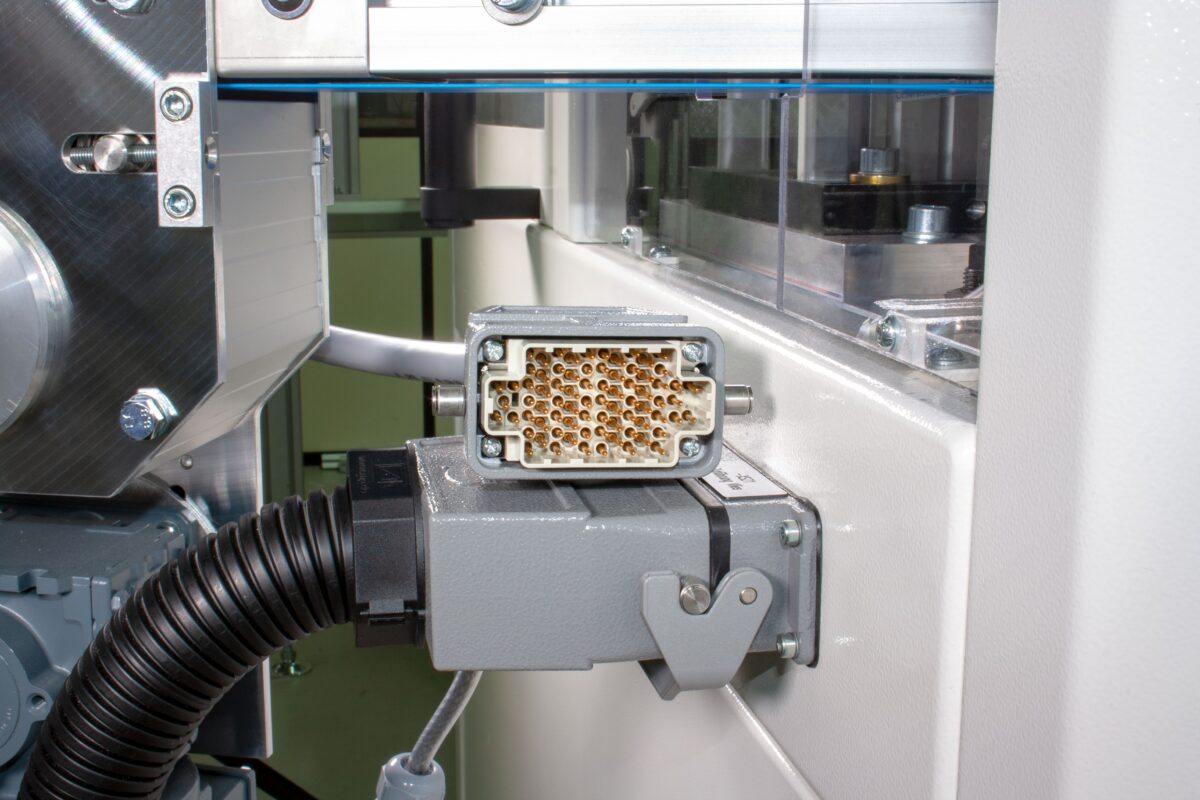

High Density Signal Connectors for Hydrogen Applications (Han® DDD)

- Up to 130% higher contact density without reduction in rated voltage

- Process optimization: One termination technology for electrical and PE contacts

- Reduction of assembly times: No additional accessories and tools for PE-connection necessary

- Additional space savings: Connector size can be reduced

- High density signal connectors available from size 6 to 16B

- Customization possible for each customer requirement

High density signal connectors for hydrogen applications (Han® DDD)

- The need for space-saving solutions is a fundamental theme which prompted HARTING’s development of the Han D® Series, which stands for high contact density and small dimensions.

- The Han® DDD has twice the number of contacts than the previous standard Han® DD – yet retains the same dimensions and electrical characteristics.

- The electrical power is equivalent to that of its sister product, the Han DD® (max. 250 V / 10 A).

- Han® DDD inserts can also help optimize wiring processes and the use of interfaces in conventional control cabinets.

- The new triple “D” inserts are standing for maximum contact density – up to 130% plus, compared to previous standards – without reducing the rated voltage.

Connectors guide with all variants

- Introduction

- The Han® DDD connectors are available in large number of variants. For details see Han® DDD guide – click here.

- Available from size 6 to 16B

- The “Triple D” can transmit signals or power with max. 107 contacts

- The connector series Han DDD®, Han DD® and Han D® equipped with all contacts may be used for voltages up to 250 V, pollution degree 3.

- A modified contact loading arrangement permits use up to 500 V also in the same pollution degree.

- According to DIN EN 61984 connectors should not be coupled or decoupled under electrical load.

- Features

- Shorter installation time

- Up to 130% higher contact density without reduction in rated voltage (compared to well known Han® DD inserts)

- Cost reduction: Increased number of contacts per interface

- Process optimization: One termination technology for electrical and PE contacts

- Reduction of assembly times: No additional accessories and tools for PE-connection necessary

- Additional space savings: Connector size can be reduced

- Available from size 6 to 16B

- Materials

- Insert: Polycarbonate (PC)

- Contacts: Gold and silver contacts available

- Specifications

- Approvals: IEC 61984, UL 1977

- Rated current: 10A

- Rated voltage: 250V

- Conductor cross section 0.14 to 2.5mm²

- Limiting temperature: -40°C to +125°C

- Flammability acc. to UL94: V0

- Working life: >500 mating cycles

- Pollution degree: 3

Application areas

- Signal transmission for status monitoring (voltage, temperature, etc.) of electrolyzer stack modules

- Signal transmission at control units and field devices of electrolyzer and fuel cell system

Han® DDD product connected to control cabinet

Contact us

- HARTING Technology Group is a global leader in supplying connectivity solutions for industrial technology. Interested? Please contact the vendor by filling in the contact vendor form or the request for quote form.

| Brand | HARTING |

| Manufacturing Readiness (MRL) | 0 |

| Technology Readiness (TRL) | 0 |

| Compliant with | IEC 61984 |

| Max Ambient Temperature (in °C) | 125 |

| Min Ambient Temperature (in °C) | -40 |

HARTING Technology Group

High-performance connection technology forms the basis of industrial application and product technology. The HARTING range of products and solutions comprises connectors, device connection technology and network components. HARTING products connect machines and facilities via data, signal and power. These offerings enable solutions for the following markets: automation, energy, railway, machinery, robotics, mobility and smart infrastructure. HARTING employs around 6,200 people across its 44 sales companies and 14 production locations.