H-300U Series - Integral - Bonnet Needle Valve

- UCT bonnet needle valve H-300U series is an advanced high-pressure instrumentation needle valve for regulating services. The packing bolt design, featuring easy mounting, provides the best solution for instrumentation panels.

- Pressure rated up to 5,000psig (345 barg) with SS316 structure and up to 3,000psig (200 barg) with brass structure and available with varied connections sized from 1/8" to 3/4" (3 mm-12 mm)

- This compact valve enables a relatively high level of flow regulation and long-life service.

- The H-300U series is compatible with ISO 15848 standard. “Industrial valves measurement, test and qualification procedure for fugitive emissions”

H-300U Series - Integral - Bonnet Needle Valve

- The bonnet needle valve H-300U series is an advanced high-pressure instrumentation needle valve for regulating service. The packing bolt design, featuring easy mounting, provides the best solution for instrumentation panels.

- This compact valve enables a relatively high level of flow regulation and long-life service. Special stem surface treatment, based on low temperature carbon diffusion, enables higher surface hardness with improved wear resistance, resistance to system contaminants and low operational torque.

- Every H-300U series needle valve is cleaned in accordance with Standard Cleaning and Packaging (procedure 8184). Oxygen Clean & Lubricant-Free Cleaning and packaging, in accordance with Special Cleaning and Packaging (procedure 8185), is available as an option.

- The H-300U series needle valve design has been tested for proof and burst. Every H-300U needle valve is factory tested with nitrogen at 1000 psi (69 bar) for leakage through the packing and seat. The maximum allowable leakage across the seat is 0.1 std cc/min. No detectable leakage is allowed during shell test.

Key features

- UCT Fluid Solutions H-300U series has a straight and angle pattern

- MAWP 5000 psi (345 bar), MAWT 446F (230°C)

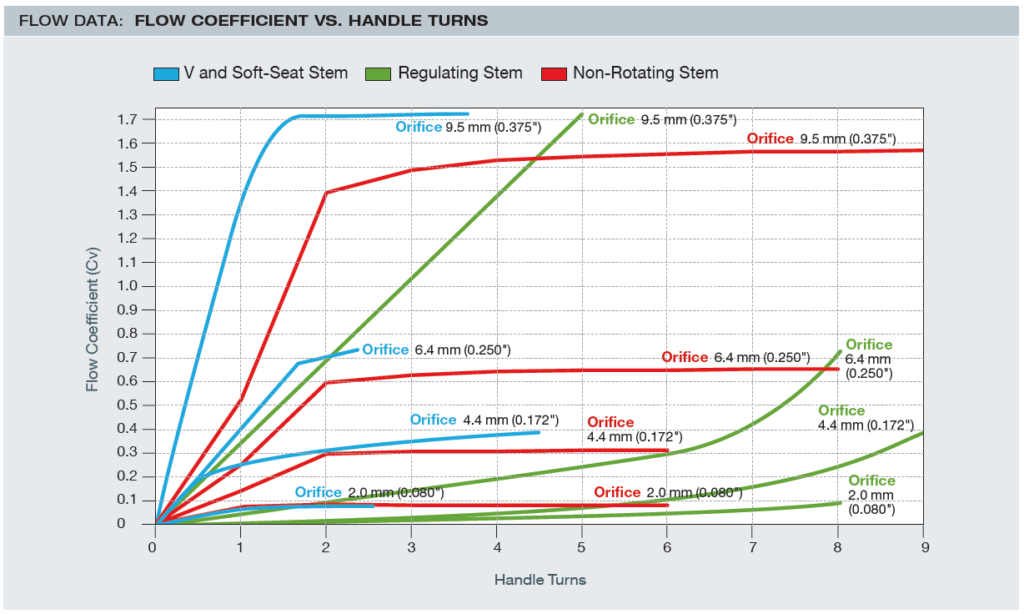

- Flow coefficient (Cv) 0.09 to 1.8

- Round plastic, round aluminum, and metal bar handles

- Packing bolt for easy panel mounting, no packing disassembly is required

- Metal bar handle is compact and designed with a shaped profile

- H-300U series is designed with a male packing nut for a longer lifetime, easy and safe paneling while keeping original valve performance.

- The H-300U series is built with 2-panel nuts for easier troubleshooting on system construction and faster installation

- H-300U series is built with Live-Loaded Chevron packing for better leak integrity and lower operating torque.

- The H-300U stem is hardened with special synthetic, anti-seize stem lubricant diffusion surface treatment for improving the corrosion resistance and eliminating galling and particle generation.

- Variety of stem types

Product chart

Application areas

- Electrolysis

- Electricity generation wind and solar

- Hydrogen storage

- Fuel cell stations

- Process system control and shut-off

- Control panels

Contact us

- Please see the technical datasheet under downloads for mounting configuration of bonnet needle valve (H-300U series). Fill out the contact vendor form to contact us today.

UCT Fluid Solutions is a leading global manufacturer and supplier of industrial high-performance high-performance flow control systems. Our broad portfolio covers the diverse needs of the various needs of the hydrogen industry in the industrial and automotive sectors automotive, with special valves, fittings, hoses, and customised solutions. Our ball valves, needle valves, and manifolds are certified according to ISO 15848-1 and ensure the lowest fugitive emissions and maximum safety when handling hydrogen. Our tube fittings are EC79-certified for use in vehicles and are tested annually by an independent laboratory. are rigorously helium tested annually by an independent laboratory to guarantee our customers that we meet the highest industry standards. By fostering innovation and creativity, UCT Fluid Solutions has developed patented products and simplified products and simplified technical solutions to meet our customers' requirements.