Gas to Liquid Plate Heat Exchanger GL150 / GLH150

- GL150 / GLH150 is a gas to liquid plate heat exchanger.

- Parallel flow direction with minimum 6 plates to maximum 140 plates.

- Maximum particle size is 1 mm

- It has stainless steel parts and copper filler giving higher robust properties against compression and temperature

- Heat transfer up to temperature of 750°C

Gas to liquid plate heat exchanger GL150 / GLH150

- The Alfa Laval GL product line is an ultra-compact, highly efficient solution that meets the unique challenges of working simultaneously with gaseous and liquid media.

- A revolutionary new design handles very high temperatures with very low pressure loss. Made with Alfa Laval's proven copper soldering technology, it also ensures the reliable performance you expect from the world market leader in thermal transfer.

- The ultra-compact Alfa Laval GL product line ensures maximum heat transfer and efficiency in asymmetric gas applications.

Design

- The brazing material seals and holds the plates together at the contact points ensuring optimal heat transfer efficiency and pressure resistance.

- Using advanced design technologies and extensive verification guarantees the highest performance and longest possible service life.

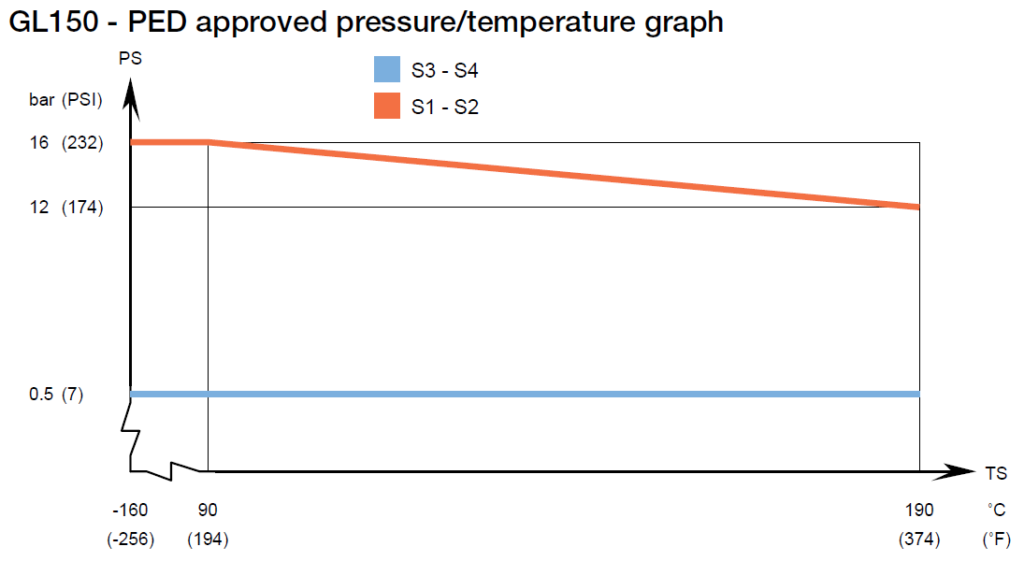

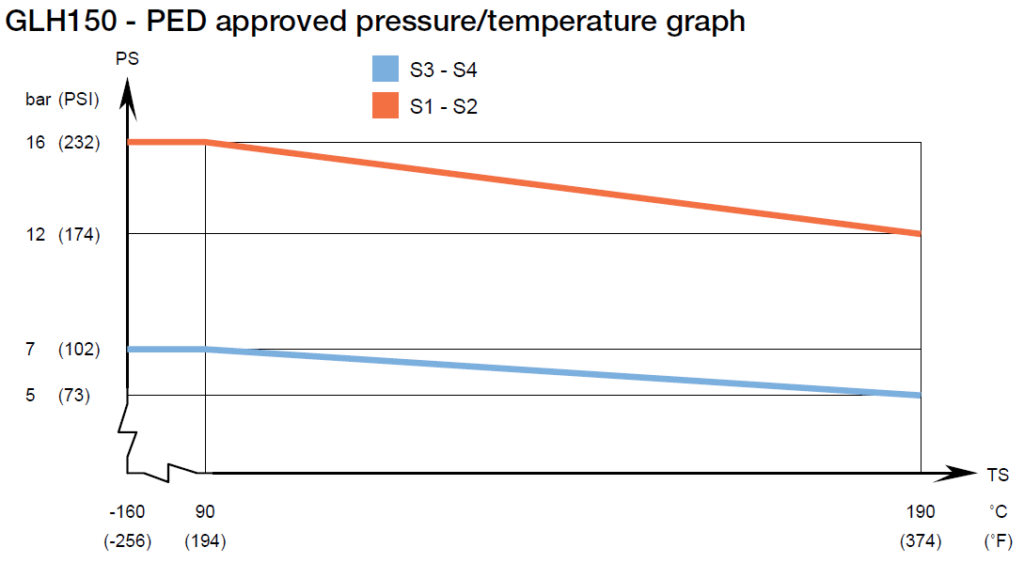

- Different pressure ratings are available for different needs. Asymmetric channels provide optimal efficiency in the most compact design. This results in very low pressure drop on the gas side.

- Alfa Laval’s unique brazed gas-to-liquid design enables much higher temperatures than traditional plate heat exchangers.

- Our standard models handles gas temperatures up to 750 ºC (1382 ºF).

Benefits

- Compact

- Easy to install

- Low level of service and maintenance required

- All units are pressure and leak tested

- Integrated gas/condensate separation

Features

- Our standard gas to liquid plate heat exchanger support gas temperatures up to 750 °C.

- Very low pressure drop in asymmetric applications thanks to patented plate design with dimple-like recesses.

- The condensate from the gas medium can easily drain off thanks to the condensate connection it contains.

How it works

- Alfa Laval's gas to liquid plate heat exchangers use thin, corrugated stainless steel plates to ensure heat transfer from one medium to another.

- Copper soldering seals the media in the plate package and results in a highly efficient heat exchanger consisting exclusively of surfaces that actively contribute to heat transfer.

- The contact points between the plates are also brazed, which improves resistance to pressure and temperature fatigue.

- The arrangement of the channels formed between the plates ensures that the media flow in countercurrent through alternating channels, further optimizing the efficiency of heat transfer.

- One channel is far larger than the other channel, so the device can handle very high flow rates.

Application areas

- Exhaust gas heat recovery

- Compressed air cooling

- Charge air cooling

- Condenser

Contact us

- We have the right heat exchanger for you. Fill out the contact us form to contact us today.

Alfa Laval is an international Swedish company active in the areas of energy, marine, and food & water, offering its expertise, products, and service to a wide range of industries in some 100 countries. With our broad portfolio of thermal and separation technologies we provide solutions for enabling the transition to green hydrogen. In electrolyser production (PEM, Alkaline, or SOEC), we offer efficient plate heat exchangers for cooling electrolytes, hydrogen and oxygen. Our plate heat exchanger portfolio also includes desalination technologies that allow you to use seawater or river water in your production, which is ideal if you operate an offshore plant. And our heat transfer solutions make it possible to recover and reuse waste heat from the electrolyser to desalinate water, or for other sustainable purposes, such as district heating. We are present in both production and storage, with unique solutions for compression and cooling, as well as innovative printed circuit heat exchangers for refueling stations. Alfa Laval has spent decades developing highly efficient and robust plate heat exchanger technologies. From our fusion bonding technique that enables reliable performance at very high temperatures, to gas-to-liquid solutions that can handle extremely uneven flow requirements, we can offer unique technologies perfect for fuel cell development.