Fusion-bonded Plate Heat Exchanger AlfaNova 52-60H

- Alfa Nova 52 series is a fusion-bonded plate type heat exchanger.

- The Alfa Nova 52-60H comes with parallel flow configuration with 60 plates.

- Maximum flow rate for Alfa Nova 52 series is 233.33 liters per minute

- 100% stainless steel parts giving higher robust properties against compression and temperature

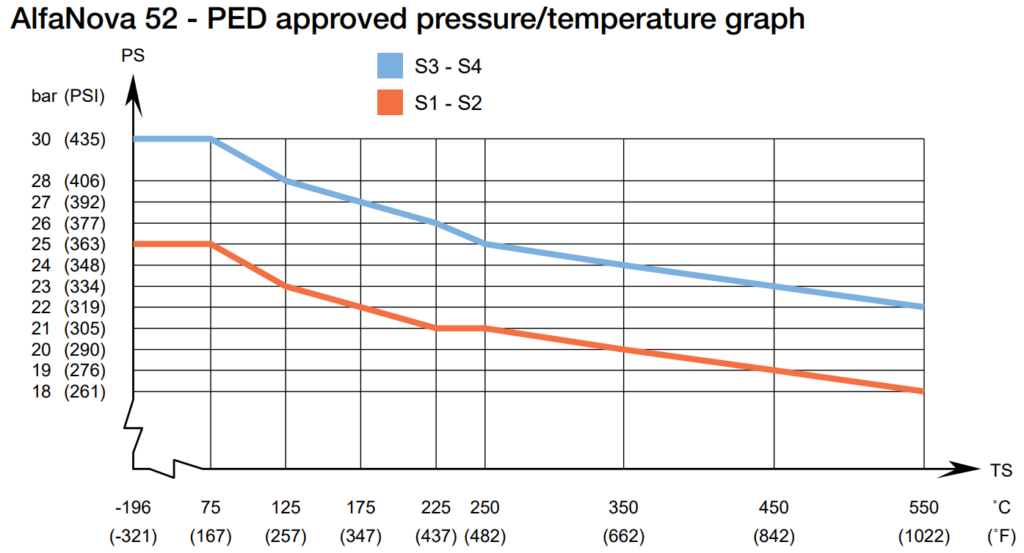

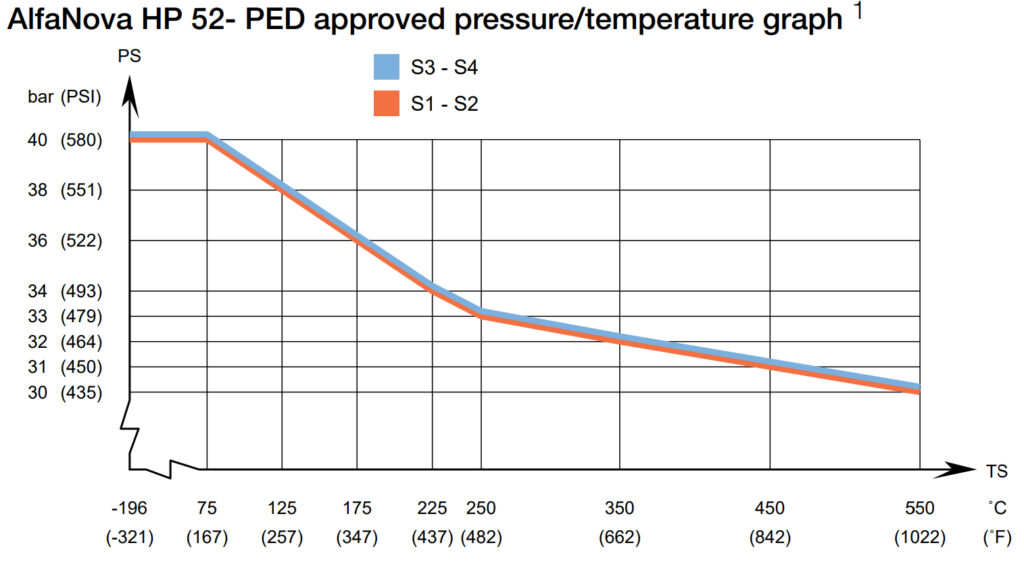

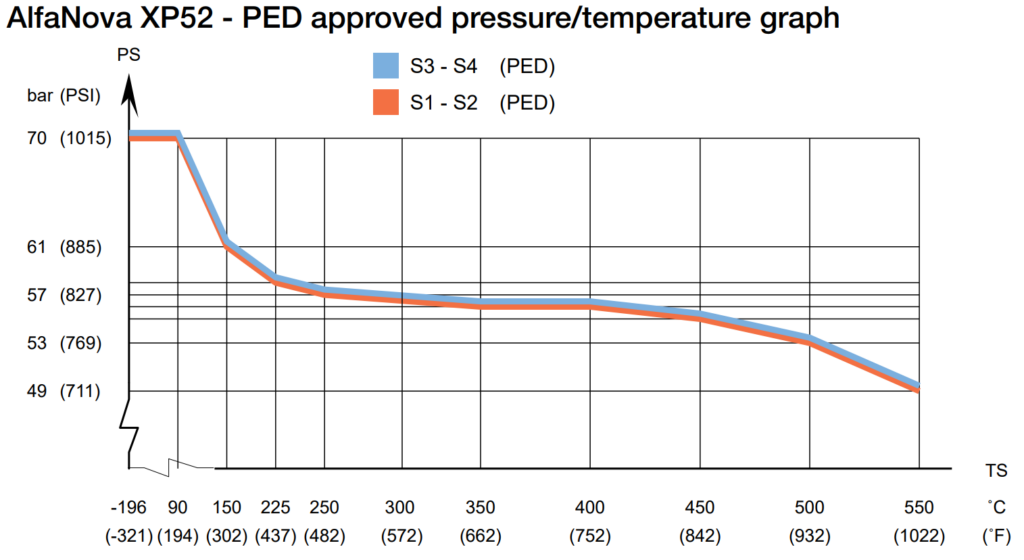

- Heat transfer up to temperature of 550°C

- Designs are calculated by Alfa Laval Mid Europe.

Fusion-bonded plate heat exchanger AlfaNova 52-60H

- Alfa Laval AlfaNova fusion-bonded plate heat exchangers are made of 100% stainless steel. They are suitable for applications which place high demand on cleanliness, applications where aggressive media like ammonia are used or where copper and nickel contamination is unaccepted.

- AlfaNova provides efficient heat transfer with a small footprint, has an extreme pressure fatigue resistance and covers high temperatures, up to 550°C/1022°F.

- The AlfaFusion filler material seals and holds the plates together at the contact points ensuring optimal heat transfer efficiency and pressure resistance. Using advanced design technologies and extensive verification guarantees the highest performance and longest possible service life.

- Based on standard components and a modular concept, each unit is custom-built to meet the specific requirements of each individual installation.

Benefits

- Compact

- Easy to install

- Self-cleaning

- Low level of service and maintenance is required

- All units are pressure and leak tested

- Gasket free

- Copper free

- High corrosion resistance

- Robust against compressive loads

- High temperature resistance

- Higher mechanical strengths

Features

- PressureSecure - unparalleled strength for demanding duties: Our innovative plate designs support the widest range of high-temperature and high-pressure applications. Units can run using thinner plates and fewer plates, which translates to less raw material, lower energy consumption, reduced refrigerant charge and a longer equipment lifecycle.

- FlexFlow - superior thermal performance: Alfa Laval’s patented asymmetrical plate design is one of many unique innovations that gives you improved thermal efficiency thanks to optimized pressure drop and increased turbulence. In addition to cutting energy consumption, that means reducing refrigerant volumes and raw materials.

- AlvaNova - 100% stainless steal: Built with 100% stainless steel, AlfaNova® is a solution that Alfa Laval offers for applications that use media not compatible with traditional heat exchanger materials. Not only is this advanced design optimized for use with natural refrigerants, it’s also completely recyclable.

- ValuePlus: Total support - with value adding options to fit your needs.

Connections examples

- External thread

- Internal thread

- Soldering

- Welding

How it works

- Two media at different temperatures flow on either side of thin corrugated stainless steel plates that are stacked on top of each other. The two media flow in a countercurrent flow through alternate channels and are held within the plate pack by a fusion-bonded seal around the edge of the plates. The points at which the plates are in contact with each other are also bonded with the same technology, reinforcing the pack against the pressure of the media inside.

- The countercurrent flow makes it possible to extract heat efficiently even when there are only extremely small differences between the temperatures of the hot and cold media. This results in notable energy cost savings.

- In some systems, co-current flows are also possible.

- View the animation to learn more.

NOTE: Values above are to be used as an indication. For exact values, please use the drawing generated by the Alfa Laval configurator or contact your local Alfa Laval representative.

Application areas

- Cooling of hydrogen compressors

- Absorption systems

- Economiser

Contact us

- We have the right heat exchanger for you. Fill out the contact us form to contact us today.

Alfa Laval is an international Swedish company active in the areas of energy, marine, and food & water, offering its expertise, products, and service to a wide range of industries in some 100 countries. With our broad portfolio of thermal and separation technologies we provide solutions for enabling the transition to green hydrogen. In electrolyser production (PEM, Alkaline, or SOEC), we offer efficient plate heat exchangers for cooling electrolytes, hydrogen and oxygen. Our plate heat exchanger portfolio also includes desalination technologies that allow you to use seawater or river water in your production, which is ideal if you operate an offshore plant. And our heat transfer solutions make it possible to recover and reuse waste heat from the electrolyser to desalinate water, or for other sustainable purposes, such as district heating. We are present in both production and storage, with unique solutions for compression and cooling, as well as innovative printed circuit heat exchangers for refueling stations. Alfa Laval has spent decades developing highly efficient and robust plate heat exchanger technologies. From our fusion bonding technique that enables reliable performance at very high temperatures, to gas-to-liquid solutions that can handle extremely uneven flow requirements, we can offer unique technologies perfect for fuel cell development.