Air Actuated Valves

Air Flow Control Valves

Angle Seat Valves

Ball Valves

Butterfly Valves

Cathode Isolation Valves

Check Valves

Coaxial Valves

Control Valves

Cryogenic Valves

Diaphragm Valves

Flow Control Valves

Globe Valves

Hydrogen Back Pressure Regulators

Hydrogen Filter Regulators

Hydrogen Fuel Cell Pressure Regulators

Hydrogen Pressure Reducing Valves

Hydrogen Pressure Relief Valves

Hydrogen Pressure Solenoid Valves

Hydrogen Tank Valves

Needle Valves

On Tank Valves

Plunger Valves

Process Automation Solenoid Valves

Proportional Valves

Safety Valves

Shut-Off Valves

Components

expand_more

Aftercoolers

Breakaways

Cell Voltage Monitors

Compressor Crankcase

Compressor Head

Converters

Couplings

Current Density Meters

Customised Plastic Parts

Diaphragms

Electrolyser Cells

Foils

Fuel Cell Air Compressors

Fuel Cell Humidifiers

Fuel Cell Plates

Gas Handling Units

Gaskets

Hydrogen Burners

Hydrogen Fittings

Hydrogen Flow Controllers

Hydrogen Fueling Nozzles

Hydrogen Gas Boosters

Hydrogen Heaters

Hydrogen Hoses

Hydrogen Pumps

Hydrogen Refueling Data Interfaces

Hydrogen Tank Liners

Inverters

IoT Telemetry Device

Laminates & Coating

Laser Sources

Membrane Electrode Assembly

Pipes

Potentiostat

Power Electronics

Pressure Relief Devices

Receptacles

Seals

Thermocouples

Transducers

Tube Connections

Tubes

Valve Manifold

Valves

expand_more

Vents

Air Actuated Valves

Air Flow Control Valves

Angle Seat Valves

Ball Valves

Butterfly Valves

Cathode Isolation Valves

Check Valves

Coaxial Valves

Control Valves

Cryogenic Valves

Diaphragm Valves

Flow Control Valves

Globe Valves

Hydrogen Back Pressure Regulators

Hydrogen Filter Regulators

Hydrogen Fuel Cell Pressure Regulators

Hydrogen Pressure Reducing Valves

Hydrogen Pressure Relief Valves

Hydrogen Pressure Solenoid Valves

Hydrogen Tank Valves

Needle Valves

On Tank Valves

Plunger Valves

Process Automation Solenoid Valves

Proportional Valves

Safety Valves

Shut-Off Valves

Equipment

expand_more

Systems

expand_more

Automation Systems

Deoxygenation Systems

Fuel Cell Exhaust Air Systems

Fuel Cell Systems

Hydrogen Cooling Systems

Hydrogen Dispensers

Hydrogen Power Generators

Hydrogen Production Unit

Hydrogen Refueling Modules

Hydrogen Refueling Stations

Hydrogen Refueling Trailers

Hydrogen Storage Systems

Hydrogen Treatment Systems

Nitrogen Generators

Process Monitoring Systems

Remote I/O Systems

Reversible Fuel Cell Systems

Services

expand_more

by Country

expand_more

Brands

Albania

Algeria

Andorra

Argentina

Australia

Austria

Bahrain

Belarus

Belgium

Bolivia

Bosnia & Herzegovina

Brazil

Brunei

Bulgaria

Cameroon

Canada

Chile

China

Colombia

Costa Rica

Croatia

Cyprus

Czechia

Denmark

Ecuador

Egypt

Estonia

Finland

France

Georgia

Germany

Gibraltar

Greece

Grenada

Hong Kong SAR China

Hungary

Iceland

India

Indonesia

Ireland

Israel

Italy

Japan

Jordan

Kazakhstan

Latvia

Liechtenstein

Lithuania

Luxembourg

Madagascar

Malaysia

Malta

Mexico

Moldova

Monaco

Montenegro

Morocco

Namibia

Netherlands

New Zealand

Nicaragua

Nigeria

Norway

Oman

Pakistan

Panama

Paraguay

Peru

Philippines

Poland

Portugal

Puerto Rico

Qatar

Romania

Saudi Arabia

Serbia

Singapore

Slovakia

Slovenia

South Africa

South Korea

Spain

Sri Lanka

Sweden

Switzerland

Taiwan

Thailand

Tunisia

Türkiye

Ukraine

United Arab Emirates

United Kingdom

United States

Uruguay

Venezuela

Vietnam

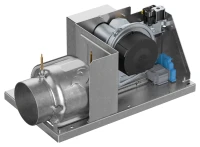

EcoLyzer A600 - Alkaline Electrolysers

- Alkaline Electrolysers for the Production of Green Hydrogen

- Cost-effective, reliable H2 generation

- No use of rare earths or precious metals

- On demand: appropriate voltage supply, water treatment, gas cleaning and / or compression

- Worldwide service network (remote and on-site)

EcoLyzer A600 - Alkaline Electrolysers for the Production of Green Hydrogen

- The alkaline electrolysis process has been used for decades for cost-effective, reliable H2 generation.

- Information on the service life of the most important components is based on reliable experience.

- Our customers appreciate the high level of operational reliability, the low maintenance requirements and the low maintenance costs.

- The use of rare earths or precious metals is completely excluded with our alkaline electrolyser. In this way we are helping the environment in the long term, guaranteeing lasting security of supply at national level and ensure that the stacks can be recycled in an environmentally friendly manner at the end of their lifetime.

Key features

- Due to the scalability and the modular design of our electrolysers, systems in the range of 1-20 MW system output can be easily configured or subsequently expanded.

- On request, we can also supply the appropriate voltage supply, water treatment, gas cleaning and / or compression.

- Our service ensures that your electrolyser produces hydrogen permanently and reliably. To this end, we offer our customers a worldwide service that can be reached at any time via our remote service or that regularly carries out professional maintenance on site.

- Efficient, Durable and Sustainable: the EcoLyzer Model Series

Areas of Application

- Sustainable and CO2-neutral supply in all sectors

- Industry: In industry, hydrogen is needed in large quantities as a raw material or as a substitute for other fossil fuels.

- Mobility: Hydrogen is the fuel of the future on the road to CO2-neutral mobility.

- Energy: Hydrogen in energy supply - easy to transport and store.

- Communities: Community solutions are decentralized solutions from power generation to heat supply.

Technical Data: EcoLyzer A600

| Performance Class | 3 MW |

| Energy connection electrolysis | 2.7 MVA |

| Voltage electrolysis | 10 kV |

| Power connection for ancillaries (*) | 0.33 MVA |

| Voltage auxiliary units | 400 V |

| Hydrogen production | 600 Nm³/h |

| Dynamics in the H2 production area | 10 - 100 % |

| Hydrogen quality | 99.9% |

| Hydrogen outlet pressure | 0.4 bar |

| Process temperature KOH | 80 - 90 °C |

| Possibility of heat extraction | yes |

| Water quality | Demin. Water (< 5 μs/cm) |

| Water consumption | approx. 600 l/h |

| Process module dimensions (**) LxWxH | 12,2 x 2,45 x 2,9m |

| Ambient temperature(***) | -20°C - 40 °C |

| Lifetime stack | 80.000 h |

| Efficiency stack | 4.5 kWh/Nm³ |

(*) including cooling | (**) Outdoor module, additional options not included | (***) with optional heating system, standard +5 - 40 °C

Contact us

- Interested? Please contact Ecolyzer by filling in the contact vendor form or RFQ form.

| Brand | EcoLyzer by Ecoclean |

| Type of Electrolyser | Alkaline |

| H2 Production Rate (in Nm³/h) | 600 |

| Max Outlet Pressure (bar) | 0.4 |

| Max Ambient Temperature (in °C) | 40 |

| Min Ambient Temperature (in °C) | -20 |

Ecoclean GmbH

Ecoclean is represented worldwide and has been successfully active in the field of plant engineering for many years. Our many years of experience in the construction of special plants for the automotive industry and our experience in the field of near-series plants for the supplier industry are a perfect match for the requirements of the hydrogen market. Our strengths in the cost-effective construction of plants coupled with the know-how to build customer-specific special plants help us and our customers.

More information: www.ecoclean-group.net | www.ecolyzer.com

Latest products

keyboard_arrow_left

keyboard_arrow_right