- What are Ultracapacitors?

- What are the main components of Ultracapacitors?

- Explain the basic working principle of an ultracapacitor?

- What are the purposes of ultracapacitors for hydrogen solutions?

- How are ultracapacitors different from batteries?

- What are the key factors in selecting ultracapacitors for hydrogen solutions?

- What are the advantages of using ultracapacitors for hydrogen solutions?

- Explain the safety considerations important when integrating ultracapacitors into hydrogen systems.

- What certifications and standards are relevant for ultracapacitors in hydrogen applications?

Browse all ultracapacitors from leading suppliers on our marketplace!

What are Ultracapacitors?

Ultracapacitors (also known as supercapacitors or electrochemical capacitors) are energy storage devices that bridge the gap between traditional capacitors and batteries. They store and release energy through an electrostatic process rather than a chemical reaction, allowing them to provide high power densities and rapid charge/discharge capabilities compared to conventional batteries.

What are the main components of Ultracapacitors?

Ultracapacitors consist of several key components that work together to store and release electrical energy. The basic components of an ultracapacitor include:

- Electrodes: Ultracapacitors have two electrodes, one positive (cathode) and one negative (anode), typically made of a high-surface-area conductive material, such as activated carbon or other carbon-based materials. These electrodes provide the surfaces where electrical energy is stored through the accumulation of charges.

- Separator: The separator is a non-conductive material placed between the two electrodes to prevent direct electrical contact while allowing the movement of ions. It helps maintain the separation of charges, preventing short circuits and ensuring the proper functioning of the ultracapacitor.

- Electrolyte: The electrolyte is a conductive solution or material that facilitates the movement of ions between the two electrodes. It plays a crucial role in the electrostatic storage of energy. Different electrolytes, such as aqueous or organic, can be used in ultracapacitors.

- Current Collectors: Current collectors are conductive materials that collect the electrical current generated during the charge and discharge processes. They connect the electrodes to the external circuit and allow the flow of electrical energy between the ultracapacitor and the connected device.

- Cell Casing: The ultracapacitor components are enclosed within a protective casing to prevent contamination and damage. The casing also helps maintain the integrity of the internal components and ensures the safety of the device.

- Terminal Connections: Ultracapacitors have terminals or connectors that allow them to be connected to external circuits or devices for charging and discharging.

Explain the basic working principle of an ultracapacitor?

The fundamental working principle of an ultracapacitor is as follows:

Charging: When a voltage is applied across the electrodes (positive voltage to one electrode and negative voltage to the other), electrons are driven out of one electrode and onto the other. This accumulation of electrons on the surface of the electrodes creates a double layer of charges – one layer of positive ions at the negative electrode and a corresponding layer of negative ions at the positive electrode. This is known as the electric double layer.

Energy Storage: The energy is stored primarily in the electric double layer and is proportional to the surface area of the electrodes and the square of the voltage applied. Due to the high surface area of the porous electrode materials and the very small separation between them, ultracapacitors can store a significant amount of energy in this electric double layer.

Quick Charge and Discharge: The energy stored in an ultracapacitor can be quickly released when needed. Unlike batteries that involve chemical reactions, ultracapacitors release energy through the movement of ions within the electrolyte and the redistribution of charges across the double layer. This enables ultracapacitors to deliver high power outputs and rapid charge and discharge cycles.

Cycling: Ultracapacitors are designed to withstand a large number of charge and discharge cycles without significant degradation. This is because there are no chemical reactions taking place that degrade the electrode materials over time, as is the case in batteries.

What are the purposes of ultracapacitors for hydrogen solutions?

In the context of the hydrogen field, ultracapacitors can serve several purposes:

- Hydrogen Fuel Cell Systems: Supercapacitors can be used in conjunction with hydrogen fuel cells to enhance system performance. Fuel cells generate electricity through a chemical reaction between hydrogen and oxygen, and they have limitations in providing sudden bursts of power or handling rapid load changes. Ultracapacitors can act as a buffer, absorbing excess energy during periods of low demand and releasing it during high demand, thus ensuring stable and efficient operation of the fuel cell system.

- Energy Recovery and Regeneration: In hydrogen-based transportation systems, such as hydrogen-powered vehicles or trains, ultracapacitors can capture and store energy during regenerative braking. When the vehicle slows down or stops, the electric motor can act as a generator, converting kinetic energy back into electrical energy. This energy can be quickly stored in ultracapacitors and then re-used to provide an extra boost of power during acceleration, reducing overall energy consumption.

- Load Balancing: In hydrogen production and distribution systems, ultracapacitors can help balance the load and manage fluctuations in energy demand. They can provide rapid bursts of power to meet sudden increases in demand or stabilize the grid by absorbing excess energy during periods of low demand.

- Backup Power and Start-Up: Ultracapacitors can be employed as backup power sources in hydrogen infrastructure, ensuring a reliable power supply during brief outages or when starting up critical systems. They can provide instant energy to start pumps, compressors, or other essential equipment, reducing the need for large, slow-response batteries.

- Cold Start: In cold climates, hydrogen fuel cells can face challenges during startup due to sluggish chemical reactions at low temperatures. Ultracapacitors can provide the necessary power to overcome these challenges and facilitate a quicker and more reliable startup of the hydrogen fuel cell system.

Ultracapacitors offer advantages such as high-power density, long cycle life, and rapid charge/discharge capabilities, making them valuable components in the hydrogen field where dynamic energy management, efficient energy recovery, and enhanced system performance are crucial.

How are ultracapacitors different from batteries?

| Aspect | Ultracapacitors | Batteries |

| Energy storage mechanism | Stores energy through electrostatic charge separation on high-surface-area electrodes | Stores energy through chemical reactions in electrodes and electrolyte. |

| Energy density | Has less energy density compared to batteries | Have higher energy density, storing more energy per unit weight or volume. |

| Power density | Have higher power density, enabling quick energy delivery and absorption | Lower power density compared to ultracapacitors |

| Charge and Discharge Rates | Capable of rapid charge and discharge, making them suitable for high-power operations | Slower charge and discharge rates compared to ultracapacitors |

| Cycle Life | Tend to have longer cycle life with minimal degradation, especially with high-frequency cycling | Have finite cycle life with capacity and performance degradation over time |

| Charging/Discharging Time | Charge and discharge quickly, reducing downtime | Typically require more time for charging and discharging |

| Temperature Sensitivity | Less sensitive to temperature variations, capable of efficient operation across a wide range | Sensitive to temperature variations, leading to performance reduction at extreme temperatures |

| Toxic materials | Does not contain harmful chemicals or toxic metals | Contains toxic and environmentally harmful chemicals |

What are the key factors in selecting ultracapacitors for hydrogen solutions?

- Charge and Discharge Efficiency: Efficiency in energy transfer is important for system performance. Look for ultracapacitors with high charge and discharge efficiency to minimize energy losses during operation.

- Size and Form Factor: Consider the physical size and form factor of the ultracapacitors, as this will impact their integration into your hydrogen-based system. Ensure that the selected ultracapacitors can be accommodated within the available space.

- Safety Features: Look for supercapacitors that include built-in safety features such as over-voltage protection, under-voltage protection, over-current protection, and thermal protection. These features can enhance the overall safety and reliability of your system.

- Voltage Stability: Evaluate the voltage stability of the ultracapacitors, especially during rapid charge and discharge cycles. Voltage fluctuations can impact the stability of other system components.

- Environmental Conditions: Consider any specific environmental conditions that your hydrogen-based system might encounter, such as humidity, vibration, or shock. Choose ultracapacitors that are designed to withstand these conditions.

- Integration Complexity: Assess the ease of integrating the chosen ultracapacitors into your hydrogen-based system. Compatibility with existing system components and ease of electrical connections are important considerations.

- Future Scalability: Consider the potential for future system expansion or scalability. Choose ultracapacitors that can be easily integrated into a larger or more complex hydrogen-based setup if needed.

Ultimately, the selection of supercapacitors for hydrogen-based systems requires a careful analysis of your specific system requirements, performance goals, and safety considerations. Collaborate with experts such as AEP hybrid power who are experienced in both ultracapacitor technology and hydrogen applications to make informed decisions that align with the project’s objectives.

What are the advantages of using ultracapacitors for hydrogen solutions?

Using ultracapacitors in hydrogen solutions offers several advantages that can enhance the performance, efficiency, and overall effectiveness of these systems. Here are some key advantages:

- Rapid Energy Storage and Release: Ultracapacitors can store and release energy very quickly, making them well-suited for applications that require rapid bursts of power, such as hydrogen fuel cell startups, regenerative braking in hydrogen-powered vehicles, and power buffering in hydrogen production systems.

- High Power Density: Supercapacitors have a high power density, meaning they can deliver high power outputs for short durations. This is valuable in situations where a sudden surge of power is needed, such as during acceleration or when compensating for temporary energy imbalances in hydrogen-based systems.

- Long Cycle Life: Ultracapacitors can endure a large number of charge and discharge cycles without significant degradation. This long cycle life makes them durable and suitable for applications that involve frequent charge and discharge events, such as energy storage and power delivery in hydrogen solutions.

- Efficiency: Ultracapacitors have high charge and discharge efficiencies, which means minimal energy loss during the energy storage and release process. This efficiency contributes to the overall energy conservation and performance of hydrogen systems.

- Temperature Tolerance: Many supercapacitors can operate effectively over a wide temperature range, making them suitable for hydrogen solutions that may encounter varying environmental conditions.

- Regenerative Braking and Energy Recovery: In hydrogen-powered vehicles, ultracapacitors can capture and store energy during regenerative braking, which would otherwise be wasted. This stored energy can then be used to assist during acceleration or to provide additional power when needed.

- Voltage Stabilization: Ultracapacitors can help stabilize voltage fluctuations in hydrogen systems, ensuring consistent power delivery and improving the efficiency of energy conversion processes.

- Backup Power: Ultracapacitors can serve as backup power sources in case of hydrogen system failures or disruptions. They can provide critical power for a short duration, allowing for safe shutdown procedures or emergency operations.

- Scalability: Ultracapacitors can be easily integrated into various sizes of hydrogen solutions, from small-scale portable devices to large industrial setups, offering flexibility and scalability.

- Reduced Maintenance: Ultracapacitors have a relatively low maintenance requirement compared to some other energy storage solutions. This can lead to cost savings and reduced downtime for maintenance tasks.

- Compact Size: Ultracapacitors are compact and lightweight, making them suitable for applications where space is limited, or weight is a concern.

- Environmental Benefits: Ultracapacitors are environmentally friendly and produce minimal waste. They do not contain toxic materials or chemicals, making them a sustainable choice for energy storage in hydrogen systems.

While ultracapacitors offer numerous advantages, it’s important to carefully assess their suitability for specific hydrogen applications and to consider the system’s overall requirements, including power, energy, and safety considerations, before integration.

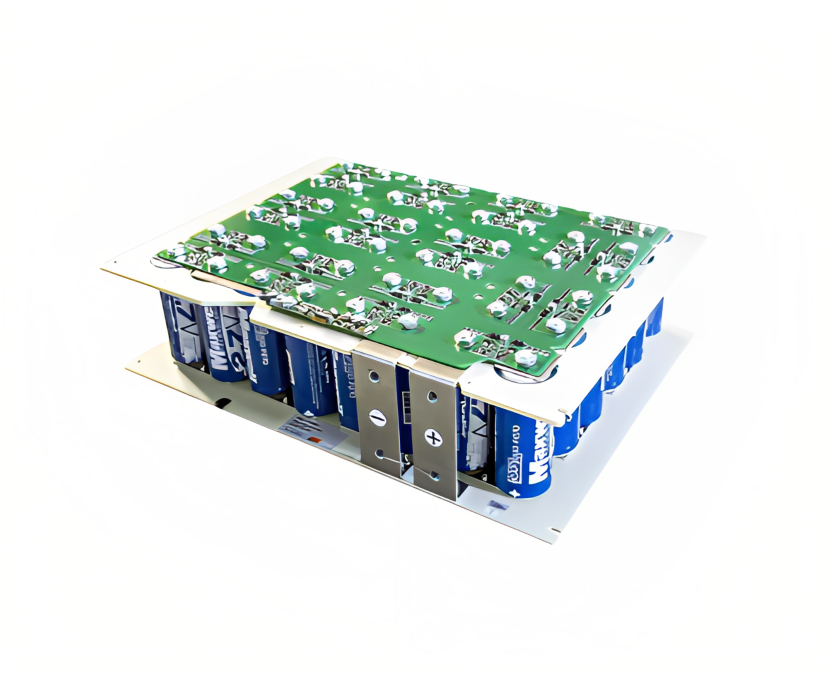

Example- Ultracapacitors for hydrogen applications

Explain the safety considerations important when integrating ultracapacitors into hydrogen systems.

Integrating ultracapacitors into hydrogen-based systems requires careful consideration of safety factors to ensure the overall reliability and security of the system. Here are some important safety considerations:

- Hydrogen Compatibility: Ensure that the materials used in the construction of the ultracapacitors are compatible with hydrogen. Hydrogen is a small molecule that can permeate certain materials, potentially leading to embrittlement or other safety issues over time.

- Hydrogen Leakage Detection: Implement sensors and monitoring systems to detect any hydrogen leaks. Rapid detection of leaks is crucial to prevent the buildup of potentially flammable hydrogen gas in the vicinity of the ultracapacitors.

- Electrical Isolation: Ensure proper electrical isolation of the ultracapacitors to prevent any potential electrical arcing or short circuits that could ignite hydrogen gas.

- Pressure Management: Integrate pressure relief mechanisms to prevent over-pressurization within the system. This is especially important if hydrogen gas is involved, as excessive pressure could lead to ruptures or failures.

- Thermal Management: Ultracapacitors can generate heat during charging and discharging. Effective thermal management systems are necessary to prevent overheating, which could potentially lead to fires or other safety hazards.

- Ignition Sources: Identify and mitigate potential ignition sources, such as sparks, open flames, or hot surfaces, in the vicinity of the ultracapacitors. Avoid design configurations that could create conditions conducive to ignition.

- Hydrogen Sensors and Alarms: Install hydrogen sensors and alarms to provide early warning of hydrogen leaks. These alarms can trigger appropriate actions to prevent hazardous situations.

- Isolation and Containment: Design the system to isolate ultracapacitors from potential hydrogen sources, such as hydrogen storage or fuel cells. This containment strategy prevents the spread of potential hazards.

- Testing and Certification: Ensure that the ultracapacitors used in the system meet relevant safety standards and certifications to guarantee their suitability for hydrogen-based environments.

- System Design and Layout: Plan the layout and arrangement of components to minimize potential risks and ensure safe distances between hydrogen-related elements and ultracapacitors.

- Monitoring and Maintenance: Implement regular monitoring and maintenance routines to identify and address potential safety issues before they escalate.

What certifications and standards are relevant for ultracapacitors in hydrogen applications?

Ultracapacitors used in hydrogen solutions might need to adhere to various certifications and standards to ensure their safety, performance, and compatibility with hydrogen systems.

- UL (Underwriters Laboratories) Standards: UL is a widely recognized certification organization. Depending on the specific application and safety requirements, ultracapacitors used in hydrogen solutions might need to comply with UL standards, such as UL 1973 for batteries and UL 2271 for energy storage systems.

- IEC (International Electrotechnical Commission) Standards: IEC develops and publishes international standards for electrical and electronic devices. Relevant standards might include IEC 62576 for ultracapacitors and IEC 62282 for fuel cell technologies.

- ISO (International Organization for Standardization) Standards: ISO standards cover a wide range of industries and technologies. For hydrogen solutions, standards such as ISO 19880-1:2018 for hydrogen fueling stations and ISO 22734-1:2019 for hydrogen generators using water electrolysis could be relevant.

- SAE (Society of Automotive Engineers) Standards: SAE develops standards primarily for the automotive and aerospace industries. Ultracapacitors used in hydrogen-powered vehicles might need to adhere to SAE standards related to vehicle electrification and hydrogen technologies.

- NFPA (National Fire Protection Association) Standards: NFPA provides codes and standards related to fire safety. Depending on the application, ultracapacitors in hydrogen solutions might need to comply with NFPA 2: Hydrogen Technologies Code or other relevant NFPA standards.

- CE Marking: If ultracapacitors are intended for sale in the European Union, they might need to carry the CE marking, indicating compliance with relevant European Union directives and standards.

- Industry-Specific Standards: Depending on the specific industry or application within the realm of hydrogen solutions, there could be industry-specific standards that ultracapacitors need to meet. For example, standards set by hydrogen fuel cell vehicle manufacturers or hydrogen infrastructure providers.

- Safety Standards for Hydrogen Compatibility: Ultracapacitors used in hydrogen environments need to meet safety standards to prevent potential hazards related to hydrogen leakage or ignition. These safety standards could be specific to hydrogen compatibility and might vary based on the intended use.

Content contributed by AEP Hybrid Power

AEP Hybrid Power is innovative in energy storage and power electronics. They supply unique Ultracapacitor cells, energy storage modules, chargers, converters and systems. They are also heavily involved in the design, development and system integration of custom-made solutions. AEP Hybrid Power is your total partner from the preliminary consultations, engineering, installation and commissioning of your system right through to the after-sales service and supply of spare parts. They enable our customers to focus on their core business by offering them a complete solution – from control & monitoring software and power electronics (such as converters) right through to housing, connection and mounting options. AEP Hybrid Power use their expertise to offer custom-made modules that meet even the most challenging requirements.