- What is the process of photochemically etching bipolar plates?

- How does photochemical etching differ from other methods of bipolar plate manufacturing?

- Which materials can be photochemically etched for bipolar plate production?

- What equipment is commonly used for photochemical etching?

- What are the advantages of photochemical etching and the benefits of using photochemically etched bipolar plates in fuel cells?

- How is the precision of the etching process controlled?

Browse fuel cell plates from leading suppliers on our marketplace!

What is the process of photochemically etching bipolar plates?

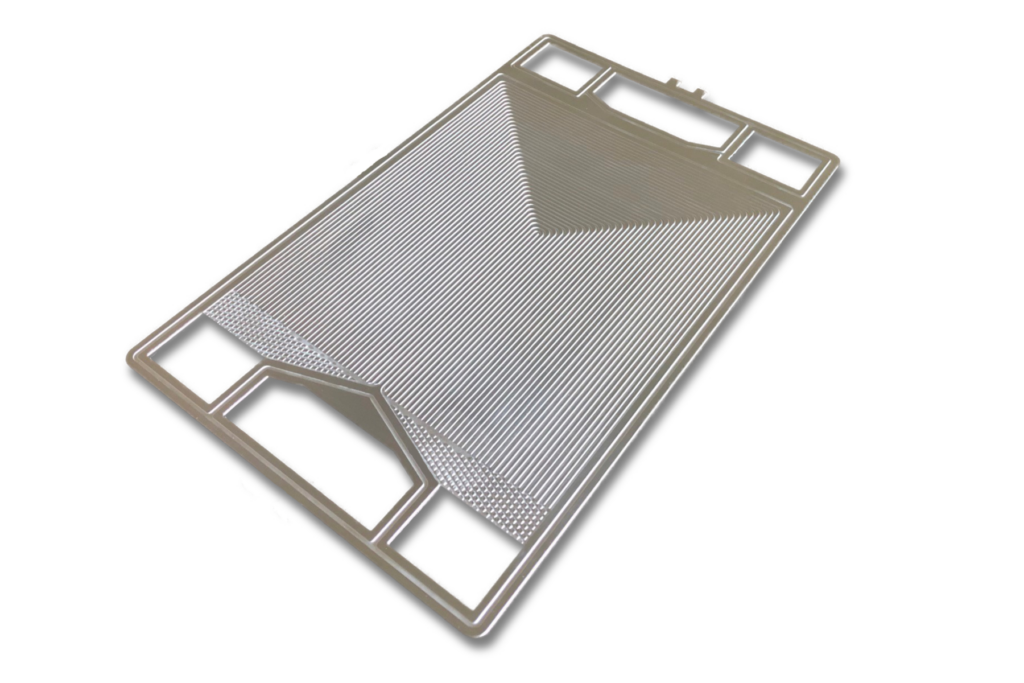

Photochemical etching is a process that uses a photosensitive coating and UV light to create a pattern on a metal sheet. The patterned coating protects the metal while a chemical solution selectively removes metal, leaving behind the desired shape. This process can be used to create channels and other features on bipolar plates for fuel cells and electrolyzers.

Bipolar plates are an essential component of a fuel cell, as they separate the individual cells and the pathway for water and gases which also serve to cool the electrolyzer. They are typically made from graphite, stainless steel or titanium. Metal plates can be expensive and difficult to manufacture using mechanical methods.

Photochemical etching can provide an alternative method for manufacturing bipolar plates that is more cost-effective and flexible. The process involves the following steps:

- Metal sheet preparation: A thin metal sheet, such as stainless steel, is cleaned and coated with a photosensitive material, such as a dry film photoresist.

- Exposure to UV light: The metal sheet is then exposed to UV light through a mask or using a digital printer to create a pattern. After exposure the unexposed resist is removed, leaving a pattern of bare metal and photoresist film.

- Chemical etching: The metal sheet is then sprayed with a chemical solution, such as an acid or alkali, that etches away the bare metal. The remaining areas of the metal sheet that were protected by the film form the desired shape and features of the bipolar plate.

- Cleaning and finishing: The bipolar plates are then cleaned and finished to remove any remaining photoresist film and to improve their surface quality.

This process can produce bipolar plates with high precision, complex geometries, and excellent reproducibility. It is also a relatively fast and cost-effective process, making it an attractive option for mass production.

How does photochemical etching differ from other methods of bipolar plate manufacturing?

The photo etching process removes metal from both sides of the plates simultaneously, so complex channels of different designs can be etched at the same time. Unlike stamping, hydroforming or laser cutting, chemical etching imparts no mechanical or thermal stress on the plates, both of which can compromise stack bonding and fluid flow. Furthermore, digital pattern tooling, which is low-cost and quick to produce, can be adapted easily and inexpensively to optimize designs. There is no incremental cost with increased design complexity or features.

| Photochemical Etching | Punching/Stamping/ Hydroforming | Laser | CNC Machining | |

| Design Complexity | Fine features & complex geometries | Coarse features; limited design complexity due to tooling restrictions | Fine features & complex geometries | Fine features & complex geometries |

| Volume | High | High | Low | Low |

| Tolerances | High | Low | High | High |

| Tooling cost | Low | High | Low | Low |

| Stress | No stress | Stress at edges | Thermal stress | No stress |

| Burrs | No burrs | Partial burrs | Molten metal slag | No burrs |

| Drawbacks | Some limitations on parts greater than 1 mm thick | Long lead times & high costs for producing tooling | Can only deal with one part/feature at a time; slag on edges | Inefficient with very thin materials |

Which materials can be photochemically etched for bipolar plate production?

Typically, bipolar plates made of aluminum, stainless steel, and titanium are etched. However, here is a range of materials that can also be etched:

- Refractory metals – Molybdenum, Tungsten, Titanium, Hafnium

- Pure metals – Copper, Nickel, Palladium

- Alloys-Stainless Steels, Kovar, Phosphor bronze, Brass, Alloy 42

- Specialty Metals – CuW, BeCu, CuMo

What equipment is commonly used for photochemical etching?

The process of photochemical etching requires specialized equipment to achieve precise and accurate results. The main equipment for photochemical etching includes:

- Digital direct imager: Digital direct imaging (DDI) is a photolithography technique that involves using a digital image to create a pattern on a metal sheet or other material. In traditional photochemical etching, a photo tool is used to create a mask of the pattern on a metal sheet or other material. Using DDI, the pattern is printed directly on the sheet, without the need for a mask.

- Developing and etching tools: Developing and etching tools have tanks that contain the chemicals used in the etching process and sprayers to apply the chemicals to the metal plates. The developer is used to remove the unexposed photoresist from the metal sheet, while the etcher is used to dissolve the exposed areas of the metal sheet.

- Spray washer: To remove any remaining chemicals and debris, a spray washer is used to rinse the metal sheet after it has been etched.

- Dryer: A dryer is used to dry the metal sheet after it has been rinsed to prevent any water spots or stains from forming.

- Inspection equipment: Inspection equipment, such as digital CMMs and measuring tools, are used to inspect the quality and accuracy of the etched parts.

- CNC or laser machines: CNC or laser machines can be used to cut the etched metal sheets into the desired shape and size.

The specific equipment used in photochemical etching may vary depending on the materials, dimensions, and tolerances required for the final product.

What are the advantages of photochemical etching and the benefits of using photochemically etched bipolar plates in fuel cells?

Photochemically etched (PCE) bipolar plates have several benefits over traditional methods of fabrication for fuel cell bipolar plates, including:

- Cost-effectiveness: PCE is much faster than CNC machining and does not require the time and expense of making stamping or punching tools. The etching process uses a Direct Digital Imager (DDI) to image part designs. DDI eliminates the time and cost to produce a photographic negative or tooling, provides a high level of accuracy and precision, and digital images can be changed quickly when design modifications are needed.

- High precision: PCE offers very high precision and repeatability for channel depths and widths compared to stamping or hydroforming, critical for maintaining proper gas and coolant flow.

- Enhanced surface properties: PCE can create micro-textures on the surface of the bipolar plates that enhance their surface properties, such as wettability, adhesion, and corrosion resistance. This can improve the efficiency and durability of the fuel cell.

- Reduced weight: PCE can create thin and lightweight bipolar plates, which can improve the power density of the fuel cell and reduce its weight.

- Design flexibility: Plates can have different designs on either side. The back side does not have to be a mirror image of the front side of the plate.

How is the precision of the etching process controlled?

The precision of the photochemical etching process is controlled through a combination of factors, including the design of the mask used to define the pattern, the quality of the photoresist, the etching time and intensity, and the chemistry of the etchant.

- Mask design: The precision of the mask design and the resolution of the pattern are controlled through computer-aided design (CAD) software and the precision of the DDI tool.

- Photoresist quality: Photoresist is a light-sensitive material that is used to transfer the pattern onto the metal sheet. The quality of the photoresist can affect the resolution and precision of the pattern, and high-quality photoresists are always used to ensure a precise pattern transfer.

- Etching time and intensity: The etching time and intensity of the etching process are tightly controlled to ensure that the features are accurately created on the metal sheet. This is especially important for channel widths and depths and the shape of channel walls.

- Etchant chemistry: The chemistry of the etchant is controlled to ensure that it selectively dissolves the metal in the desired pattern while leaving the rest of the sheet intact.

Content contributed by Elcon Precision

Elcon Precision is a precision component manufacturer of many critical components. For over 60 years, we have specialized in photochemical etching, ceramic metallization, and brazed assemblies. For the hydrogen industry, we provide photochemically machined bipolar plates for electrolyzers and fuel cells. Send in your questions and drawings today! Our engineers will work with you to optimize your plate designs and costs to take you from prototype to production volumes.

Last update: 05.05.2023