Browse fuel cell stacks from leading suppliers on our marketplace!

What is a PEM fuel cell?

A proton exchange membrane fuel cell (PEMFC) is a type of fuel cell that uses hydrogen as fuel, and oxygen from the air as an oxidant. It converts the chemical energy of the hydrogen fuel into electricity by way of a chemical reaction, with water as the only residual byproduct. A PEM fuel cell is known for high efficiency, quick response time, and the ability to operate at relatively low temperatures.

How does a PEM fuel cell work?

The basic functioning of a hydrogen PEM fuel cell can be described in the following steps:

- Hydrogen is supplied to the anode (negative electrode) of the fuel cell.

- At the anode, the hydrogen molecule is split into its individual protons and electrons. The protons pass through the proton exchange membrane (PEM) to the cathode (positive electrode), while the electrons flow through an external circuit to create an electric current.

- At the cathode, the protons, electrons, and oxygen from the air combine to form water molecules.

- The chemical reaction at the anode and cathode generates electricity, which can be used to power electrical devices or stored in a battery.

The overall chemical reaction in a PEM fuel cell can be represented as follows:

Hydrogen + Oxygen → Water + Electricity

Hydrogen PEM fuel cell components

The main components of a PEM fuel cell include:

- Proton exchange membrane (PEM): A thin, porous polymer membrane that allows protons to pass through while blocking electrons.

- Anode and cathode: The electrodes where the chemical reactions take place.

- Electrolyte: A substance that conducts ions, such as protons or electrons, through a solution or solid.

- Gas diffusion layers (GDLs): Layers of porous material that distribute the gases (hydrogen and oxygen) to the electrodes and help remove water produced by the reaction.

- Bipolar plates: Plates that separate the individual fuel cells and provide a path for the gases and electrical current.

- Current collectors: Conductive materials that collect and distribute the electrical current from the fuel cell.

Designing a PEM fuel cell stack

A fuel cell stack is a group of fuel cells connected in series or parallel to increase the overall power output. To design a PEM fuel cell stack from individual PEM fuel cells, the following steps can be followed:

- Determine the desired power output and operating conditions of the PEMFC stack. This will help inform the number and size of the fuel cells needed, as well as the design of the other components.

- Gather the necessary materials and equipment, including fuel cells, bipolar plates, current collectors, PEM electrolyser, and any other necessary components.

- Assemble the fuel cells into a stack by alternating layers of fuel cells with bipolar plates.

- Connect the current collectors to the fuel cells, ensuring that the proper polarity is maintained.

- Connect the fuel cell stack to the necessary electrical and gas supply lines, including hydrogen and oxygen (air) feeds.

- Test and optimize the fuel cell stack to ensure it is functioning properly and achieves the desired performance criteria. This involves adjustment of the operating conditions, gas flow rates, and other factors.

It is important to carefully consider the design of the fuel cell stack in order to achieve the desired PEM fuel cell efficiency, power output, and other performance criteria. Proper design and testing can help ensure that the fuel cell stack functions effectively and reliably over its lifespan.

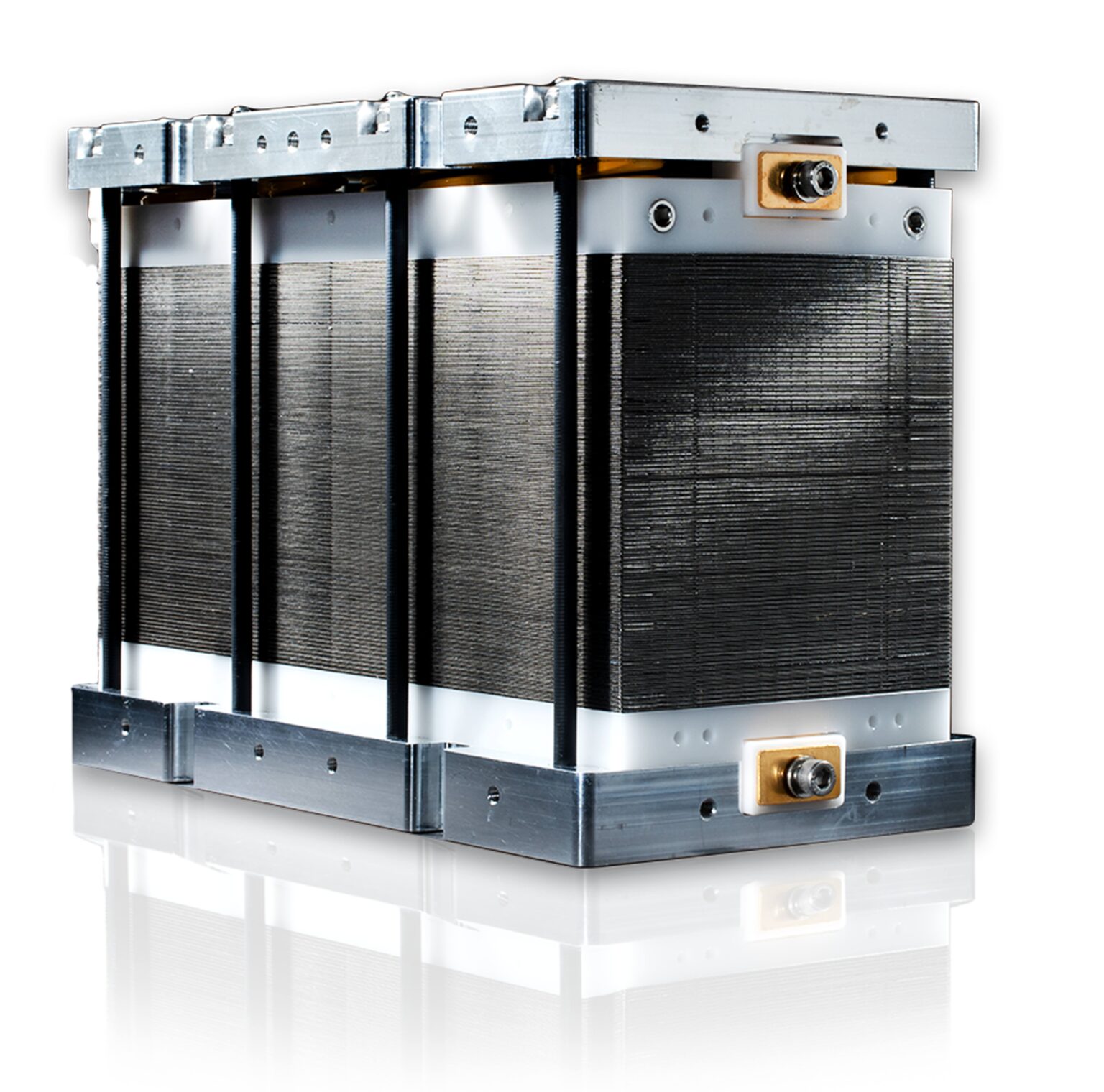

Example: PEM fuel cell stack

System design

A PEM fuel cell system consists of a fuel cell stack, as well as additional components and equipment needed to supply the fuel and oxygen, control the operating conditions, and manage the electrical output. Here is a table outlining the necessary building blocks for a PEM fuel cell system that produces electricity and a PEM electrolysis system that produces hydrogen:

| Components of a PEM fuel cell system (Electricity Production) | Components of a PEM Electrolysis System (hydrogen production) |

| Fuel cell stack | PEM electrolyser stack |

| Hydrogen gas supply | Electricity supply |

| Oxygen (air) supply | Water supply |

| Heat exchanger | Heat exchanger |

| Gas humidifier | Gas humidifier |

| Gas blender | Gas blender |

| Inverter | Electrolysis controller |

| Battery | Hydrogen storage |

High temperature PEM fuel cell

The standard PEM fuel cell design is in fact known as a “LT-PEMFC”, meaning “Low Temperature Proton Exchange Membrane Fuel Cell”. While the operation at low temperatures is desirable, this does require a high degree of purity of the hydrogen fuel of 99.9%, making an elaborate apparatus for purification of the hydrogen fuel a prerequisite to actually obtaining such desirable operating characteristics.

This has recently led to the development of HT-PEM fuel cells, namely high temperature PEM fuel cells, offering greater resilience towards hydrogen fuel impurities. The main difference to LT-PEM technology is the type of membrane used, which is made from an acid and temperature resistant polymer. Generally, polybenzimidazole (PBI) is used. This has the ability to absorb Phosphoric acid, which is used as the electrolyte. As such, HT-PEM fuel cell technology is similar to the Phosphoric Acid Fuel Cell (PAFC) design, with the main difference being the type of membrane used.

As a result, the HT-PEM fuel cell can be powered using reformate gas with a hydrogen concentration of about 50 to 75 %. Furthermore, the HT-PEM technology is not as sensitive to carbon monoxide concentrations and can operate with a CO content in the reformate gas of of up to 3 Vol %.

Use cases

PEM hydrogen fuel cells have a wide range of potential applications:

- Portable power generation: A PEM fuel cell can be used to power portable electronic devices, such as laptops and cell phones.

- Transportation: Hydrogen PEM fuel cells can be used to power vehicles, including cars, buses, trains and boats.

- Backup power: PEM fuel cells can be used as a backup power source for homes, businesses, and other types of infrastructures.

- Remote power: The PEM fuel cell design is suitable for use as a power supply in remote locations that are not connected to the grid.

PEM fuel cell performance criteria

There are four key performance criteria to consider when evaluating the performance of a PEM fuel cell i.e. power density, efficiency, response time and durability.

- Power density: The amount of power that can be generated per unit area of the fuel cell. Higher power density means that the fuel cell can produce more power in a smaller size.

- Efficiency: The percentage of the chemical energy of the fuel that is converted into electrical energy. Higher efficiency means that less energy is lost as heat or other byproducts. The PEM electrolyser efficiency is very important in this respect.

- Response time: The time it takes for the fuel cell to reach its full power output after being activated. A faster response time means that the fuel cell can respond quickly to changes in demand.

- Durability: The lifespan of the fuel cell and its ability to maintain its performance over time.

How to prevent degradation of PEM fuel cells?

There are several technical requirements that must be considered in order to prevent degradation and maintain high efficiency in a PEM Fuel Cell. These factors are mentioned below.

- Operating conditions: PEM fuel cells operate best within a specific range of temperature and humidity. It is important to maintain these conditions in order to prevent degradation and maintain efficiency.

- Gas purity: A PEM hydrogen fuel cell requires high-purity hydrogen gas in order to function effectively. Impurities in the hydrogen gas can lead to degradation and reduced efficiency.

- Water management: A PEM Fuel Cell produces water as a byproduct of the chemical reaction, and proper water management is necessary to prevent degradation and maintain efficiency. This includes ensuring that the fuel cell has sufficient access to water and removing excess water from the system.

- Membrane quality: The proton exchange membrane (PEM) is a critical component of the fuel cell, and it is important to use high-quality materials and maintain proper handling and storage in order to prevent degradation.

Last update: 15.02.2023