- What are the key components required to build a complete hydrogen gas compression system?

- How do modular compression units contribute to the flexibility and scalability of refueling stations and hydrogen storage?

- What factors influence the achievable pressure and flow rate in piston compressors and diaphragm compression systems?

- What role does inlet pressure play in determining final output pressure and flow performance in fuel cell and hydrogen energy systems?

- What are the advantages and limitations of using open-loop hydraulic systems for compression?

- Why is thermal management critical in efficient compressor solutions for hydrogen compressors?

- How is system automation typically achieved in hydrogen compression modules?

- How do buffer cylinders improve system stability in hydrogen compression circuits?

- What are the typical configurations of compressors used for refueling versus storage applications?

- Which regulatory directives and certifications are typically applicable to hydrogen compression systems in Europe?

What are the key components required to build a complete hydrogen gas compression system?

A complete hydrogen gas compression system is a highly engineered assembly of components, each critical to ensuring safe, efficient, and reliable operation under the demanding conditions of gaseous hydrogen service. The key components include:

- Hydrogen compressors and Drive System: At the core of the system, the hydrogen compressor increases gas pressure to meet specific downstream requirements. Various types of compressors—including piston, piston compressors, diaphragm compressors, and centrifugal compressors—can be used depending on the application. The compressor of choice is driven by a compatible system selected based on duty cycle, flow rate, and operating pressure. Some systems may also include advanced technologies such as electrochemical compressors for specialty industrial applications.

- Heat Exchangers and Cooling Systems: Hydrogen heats rapidly during compression, making efficient thermal management critical. Tube-in-tube heat exchangers and other efficient compressor solutions manage temperature rise, reduce thermal stress, and maintain system stability—especially under high pressures typical in hydrogen infrastructure.

- Pressure and Temperature Monitoring Instrumentation: Real-time measurement devices ensure operation within safe parameters. These are vital for process control, safety assurance, and diagnostics, particularly in systems where hydrogen embrittlement may be a concern.

- Venting System: A venting setup allows for the safe, controlled release of hydrogen during emergencies, maintenance, or purging. Proper management of hydrogen and other gases is essential in regulated environments.

- Safety Mechanisms: Robust features such as pressure relief valves, gas detection sensors, and emergency shutdown systems prevent over-pressurization and isolate the process during abnormal conditions. These are especially critical in high pressure and pressure hydrogen environments.

- Integrated Electrical Control System: Automation is typically managed via programmable logic controllers (PLCs) with supervisory control and data acquisition (SCADA) integration for real-time diagnostics and remote operation.

Each component must be selected and integrated with hydrogen's unique properties in mind. Proper system design helps mitigate risks such as hydrogen embrittlement while ensuring long-term durability and performance. These solutions are increasingly important in the broader hydrogen economy, where infrastructure must meet evolving demands in energy storage, pipelines, and electric vehicles powered by hydrogen fuel cell systems.

How do modular compression units contribute to the flexibility and scalability of refueling stations and hydrogen storage?

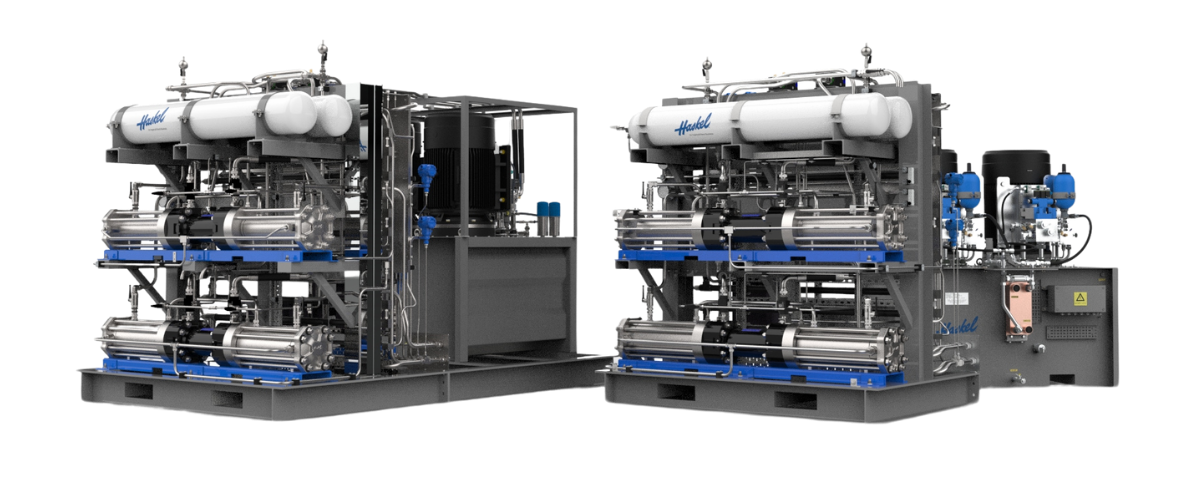

Modular hydrogen compression units offer unmatched flexibility and scalability for hydrogen infrastructure, particularly in hydrogen refueling stations and distribution systems where demand may grow incrementally.

These systems are designed around a modular framework that enables easy scaling. Key benefits include:

- Scalable Design: Additional compressor stages or hydraulic power units (HPUs) can be integrated into the existing framework, supporting increased capacity without full system replacement

- Rapid Deployment: Skid-mounted, pre-engineered modules reduce installation time and complexity, accelerating timelines and lowering commissioning costs.

- Minimized Disruption and Capital Outlay: Expansion involves minimal downtime, enabling smooth upgrades without interrupting operations.

- Redundancy and Maintainability: Dual-module configurations ensure uninterrupted operation during servicing. Modular units also ease sourcing of spare parts, streamlining ongoing support and minimizing unplanned outages.

- Compact Footprint: Self-contained modular skids simplify planning and support regulatory compliance in space-constrained settings. This is particularly valuable in automotive applications and transport hubs where hydrogen vehicles are becoming more common.

This modular approach supports hydrogen energy infrastructure growth and aligns with European reference designs advocating standardization in hydrogen refueling deployments.

What factors influence the achievable pressure and flow rate in piston compressors and diaphragm compression systems?

Performance metrics in hydrogen compression systems depend on mechanical and thermal characteristics, particularly in high-pressure hydrogen environments.

Critical Factors:

- Compressor Design: Multi-stage setups support pressures up to 950 bar.

- Piston Specifications: Larger diameters and stroke lengths allow more hydrogen throughput.

- Speed & Inlet Conditions: Speed increases flow but generates heat. Elevated natural gas or hydrogen inlet pressures can optimize performance.

- Thermal Management & System Ratings: Robust cooling and safety interlocks preserve performance and safety under stress.

Balancing these variables is key for long-term compression solutions in both storage and transport systems.

What role does inlet pressure play in determining final output pressure and flow performance in fuel cell and hydrogen energy systems?

Inlet pressure significantly influences both the performance and efficiency of hydrogen compression systems. Its effects can be observed in several key areas:

- Higher Mass Flow Rate: As inlet pressure increases, hydrogen gas becomes denser. This results in more mass being compressed per cycle, effectively increasing the flow rate without requiring a larger or faster compressor.

- Reduced Compression Ratio: A lower compression ratio translates into reduced mechanical and thermal load on the system. Compressing gas from 100 bar to 500 bar requires significantly less work than compressing it from atmospheric pressure to the same level.

- Energy Efficiency: Lower compression ratios require less energy, which reduces operational costs and contributes to a more efficient compression process.

- Stage Bypassing: In systems with multiple compression stages, higher inlet pressures may allow gas to be introduced at a later stage, bypassing earlier ones. This reduces mechanical wear and energy use.

- Improved Cooling Efficiency: Less compression work per stage reduces the amount of heat generated, easing the burden on the system’s cooling infrastructure.

Effectively managing inlet pressure can significantly improve the operational efficiency and life expectancy of the system, especially in high-demand environments such as hydrogen refueling stations or fuel cell infrastructure.

What are the advantages and limitations of using open-loop hydraulic systems for compression?

Open-loop hydraulic systems, such as those used in stationary applications, offer a balance of performance, simplicity, and cost. These systems are particularly well suited for high-duty hydrogen compression applications where continuous operation and serviceability are important.

Advantages:

- Superior Cooling: Constant oil flow through external reservoirs and chillers enables efficient heat removal, improving system stability.

- Better Contamination Control: Inline filtration keeps hydraulic oil clean, which reduces wear and extends equipment life.

- Simplified Architecture: Fewer control elements and reduced system complexity make open-loop systems easier to maintain.

- Lower Costs: Fewer components and a simplified design generally result in lower capital and maintenance costs.

Limitations:

- Reduced Responsiveness: Open-loop systems can have slower response times and less precise actuator control compared to closed-loop designs.

- Larger Footprint: They typically require more space due to external reservoirs and expanded cooling capacity.

Despite these trade-offs, open-loop systems remain a favored choice for reliable, cost-effective hydrogen compression technology in stationary or skid-mounted setups.

Why is thermal management critical in efficient compressor solutions for hydrogen compressors?

Thermal management is one of the most important aspects of hydrogen compression design. Hydrogen heats quickly when compressed, and if not properly cooled, high temperatures can compromise performance, safety, and component life.

Why It Matters:

- Temperature Rise: Compression stages—can reach internal temperatures as high as ~160°C.

- Material Degradation: Elevated temperatures can exceed the ratings of seals and gaskets, causing faster degradation and increasing maintenance requirements.

- Reduced Efficiency: As hydrogen heats, it becomes less dense. This reduces the amount of hydrogen that can be processed per cycle.

- Safety Risks: Thermal fatigue can affect mechanical integrity, increasing the risk of leaks or component failure in high-pressure systems.

Common Cooling Solutions:

- Intercoolers and Aftercoolers: Tube-in-tube heat exchangers are positioned between and after stages to cool hydrogen.

- Chilled Coolant Systems: Dedicated chillers provide coolant at 5–10 °C and flow rates around 90 LPM per hydraulic drive unit.

- Air- or Liquid-Cooled Heat Exchangers: Selected based on ambient environmental conditions.

- Integrated Automation: PLCs and HMIs monitor and adjust cooling based on stage-specific temperature data.

Thermal design often borrows from best practices in adjacent hydrogen technologies such as fuel cells and electrochemical hydrogen compressors, improving reliability and safety.

How is system automation typically achieved in hydrogen compression modules?

System automation in hydrogen compression modules is essential for ensuring safe, reliable, and efficient operation, particularly in high-pressure, continuous-use environments. Modern automation solutions leverage a combination of programmable control, sensor feedback, and intelligent interfaces to manage complex process variables in real time.

Core Components of Automation Architecture

- Programmable Logic Controllers (PLCs): These industrial controllers form the backbone of the automation system. Housed within control modules (e.g., ECMs), PLCs coordinate the operation of compressors, valves, hydraulic drives, and safety shutdown systems according to predefined logic sequences.

- Integrated Sensors: A network of sensors monitors key parameters such as pressure, temperature, flow, and seal condition. Real-time data from these sensors feeds into the PLCs, enabling continuous system evaluation and adjustment to maintain safe and optimal performance.

- Human-Machine Interface (HMI): Operators interact with the system through HMIs, where they can input target pressures, initiate startup or shutdown cycles, and monitor process conditions. The HMI also provides access to diagnostics, alarm logs, and manual override functions.

- Automated Safety and Control Logic: Control algorithms adjust compressor stage use, regulate cooling cycles, and trigger alarms or emergency shutdowns if sensor values exceed safe thresholds. This ensures that equipment stays within operating limits, even under variable conditions.

- Predictive Maintenance and Diagnostics: Advanced systems incorporate logic for monitoring wear indicators, such as bypass flow increases across seals which is often a precursor to seal degradation. This enables proactive maintenance scheduling before failure occurs, improving uptime and reducing unplanned outages.

Automation in compression systems, helps reduce reliance on operator intervention and allows for more consistent integration across distributed hydrogen infrastructure networks.

How do buffer cylinders improve system stability in hydrogen compression circuits?

Buffer cylinders play a vital role in maintaining system stability within hydrogen compression circuits by regulating gas flow and pressure fluctuations. Their use enhances operational consistency, protects mechanical components, and supports overall system reliability.

Functions and Benefits of Buffer Cylinders

- Flow Stabilization: Buffer cylinders absorb transient variations in hydrogen flow, both at the system inlet and between compression stages. By smoothing out these fluctuations, they ensure a more uniform gas supply to the compressor, reducing performance variability.

- Pressure Pulsation Dampening: Compression processes naturally introduce pulsations, especially in reciprocating piston systems. Strategically placed buffer cylinders act as dampeners, mitigating pressure spikes and cyclic loading, which in turn lowers mechanical stress on valves, seals, and piping.

- Temporary Gas Storage: In the event of a momentary drop in hydrogen supply or during brief mismatches in inter-stage flow rates, buffer cylinders provide short-term gas availability. This allows the compressor to continue operating smoothly, avoiding abrupt shutdowns or inefficient cycling.

- Enhanced System Reliability: By stabilizing operating conditions, buffer cylinders reduce wear on key components, extending maintenance intervals and improving long-term system uptime.

Buffer cylinders are considered standard components in large-scale and high-throughput hydrogen compression systems, particularly where consistent operation and equipment longevity are paramount.

What are the typical configurations of compressors used for refueling versus storage applications?

Compressor configurations for hydrogen applications differ based on whether the target use is vehicle refueling or long-term hydrogen storage:

- Refueling Applications: Two-stage systems are standard and are capable of compressing hydrogen to 700–950 bar. These compressors focus on fast cycle times and thermal management and are often skid-mounted for integration into hydrogen refueling stations.

- Storage Applications: Also typically two-stage, but optimized for continuous operation with discharge pressures ranging from 500–700 bar. These prioritize steady-state performance and may include larger buffer volumes.

In both cases, modularity allows for redundancy, ease of maintenance, and streamlined system integration. These designs are adaptable for emerging applications like fuel cell vehicles and liquid hydrogen distribution networks.

Which regulatory directives and certifications are typically applicable to hydrogen compression systems in Europe?

Hydrogen compression systems installed in Europe must meet rigorous regulatory requirements to ensure compliance with safety, performance, and environmental standards:Pressure Equipment Directive (PED 2014/68/EU): Governs pressure vessels and system components operating above 0.5 bar. Requires adherence to material traceability, pressure testing, and design conformity.Machinery Directive (2006/42/EC): Covers safety of mechanical components and

Hydrogen compression systems installed in Europe must meet rigorous regulatory requirements to ensure compliance with safety, performance, and environmental standards:

- Pressure Equipment Directive (PED 2014/68/EU): Governs pressure vessels and system components operating above 0.5 bar. Requires adherence to material traceability, pressure testing, and design conformity.

- Machinery Directive (2006/42/EC): Covers safety of mechanical components and ensures systems are designed with emergency stops, safe handling, and protection against moving parts.

- ATEX Directive (2014/34/EU): Relevant for systems in explosive atmospheres (Zone 2), requiring explosion-proof electrical and mechanical components.

- Electromagnetic Compatibility (EMC Directive 2014/30/EU): Ensures that electrical systems do not interfere with or are affected by other nearby equipment.

- Low Voltage Directive (LVD 2014/35/EU): Applies to electrical systems operating between 50 and 1,000 V AC or 75 and 1,500 V DC.

- Environmental and Site-Specific Regulations: May involve noise limitations, zoning laws, and environmental impact assessments depending on the installation context.

Content contributed by Haskel

For 75 years and counting, Haskel has been recognized as the world’s leading provider of high-pressure industrial gas and liquid handling equipment. Haskel hydrogen technology is safely and successfully used in a range of mission critical applications around the world every day - just as it has been for over two decades. We manufacture a full range of hydrogen handling equipment, including compressors, hydraulic and pneumatic-driven gas boosters, high-pressure valves and fittings and other system components. All of which use specific materials designed for hydrogen use based on pressure and flow requirements to address embrittlement issues metals face when exposed to a hydrogen environment. As the world’s leading provider of high-pressure hydrogen solutions, we have a team of experts who will work with you to provide the best solution for your chosen application.