- What is a fuel cell silencer?

- Why are filter silencers for fuel cell blowers so important?

- How do silencers for fuel cell systems work?

- Which components in a fuel cell system emit noise?

- How far can the noise level be reduced by the use of silencers?

- Can conventional silencers be used in fuel cell and hydrogen applications or do they need to be adapted?

- Which materials are used in silencers to reduces the noise level?

- Which design measures can further reduce the noise level of fuel cell systems in addition to the use of silencers?

What is a fuel cell silencer?

The fuel cell silencer plays an important role in ensuring the overall operability of the entire fuel cell system. Also known as silencer filters for fuel cell blowers and compressors, or cathode air filter silencers, these assemblies are generally integrated into the filtration system designed to clean the intake air from harmful pollutants. Design requirements often stipulate placement very close to the intake port of blower or compressor, necessitating a mitigation of noise generated in the intake duct. Acoustic attenuation in broad-band silencer designs is achieved using sophisticated baffle arrangements posing minimal impediment to the intake airflow, and/or fibrous or porous dampening materials absorbing the sound. A modular filter concept allows for quick integration into any given fuel cell design and installation, eliminating the need for extensive and time-consuming development work for any specific application.

Why are filter silencers for fuel cell blowers so important?

Even though the chemical process of generating electricity in a fuel cell system is completely quiet, the reduction of noise of other components like blowers or vacuum pumps is becoming increasingly important today, also in the application fields of fuel cell technology. To minimize the noise level of both mobile and stationary solutions, it is often sufficient to use silencers that use insulating materials to cancel out a wide range of frequencies. In this way, fuel cell systems can be used in any environment without burdening employees and the environment with noise.

How do silencers for fuel cell systems work?

a) Reactive silencers

Reactive industrial silencers are equipped with multiple chambers and perforated tubes. This leads to a redirection of the sound waves and reflects them back to the source of the sound, which reduces the volume of the noise. This type of fuel cell silencer does not contain acoustic insulation and instead attenuates sound mainly by scattering and reflecting the sound waves. These kinds of silencers are in general use for fixed-speed machines, such as generators and blowers. They are best suited for machines that produce pure tones and sounds with low to medium frequencies.

b) Absorptive Silencers

The main difference between reactive silencers and absorptive silencers is that absorptive silencers primarily attenuate sound by absorbing the sound’s energy rather than reflecting it. The reason they can do this is due to fibrous and porous sealing materials which absorb sound waves and therefore reduce the volume of sound. As the sound waves propagate through the insulating materials, some of the sound energy is converted into heat energy, which is then released into the air. Due to its absorptive behavior this type of filter silencer for fuel cell systems requires minimal airflow to properly attenuate sound.

Which components in a fuel cell system emit noise?

- High Frequency – Regenerative blowers

- Medium/variable frequency – compressors/vacuum pumps

- Lower/variable frequency – PD blowers/vacuum pumps

There are a lot of different kinds of vacuum pumps, blowers, and compressors so the above is not an exhaustive list. These are some prominent examples.

How far can the noise level be reduced by the use of silencers?

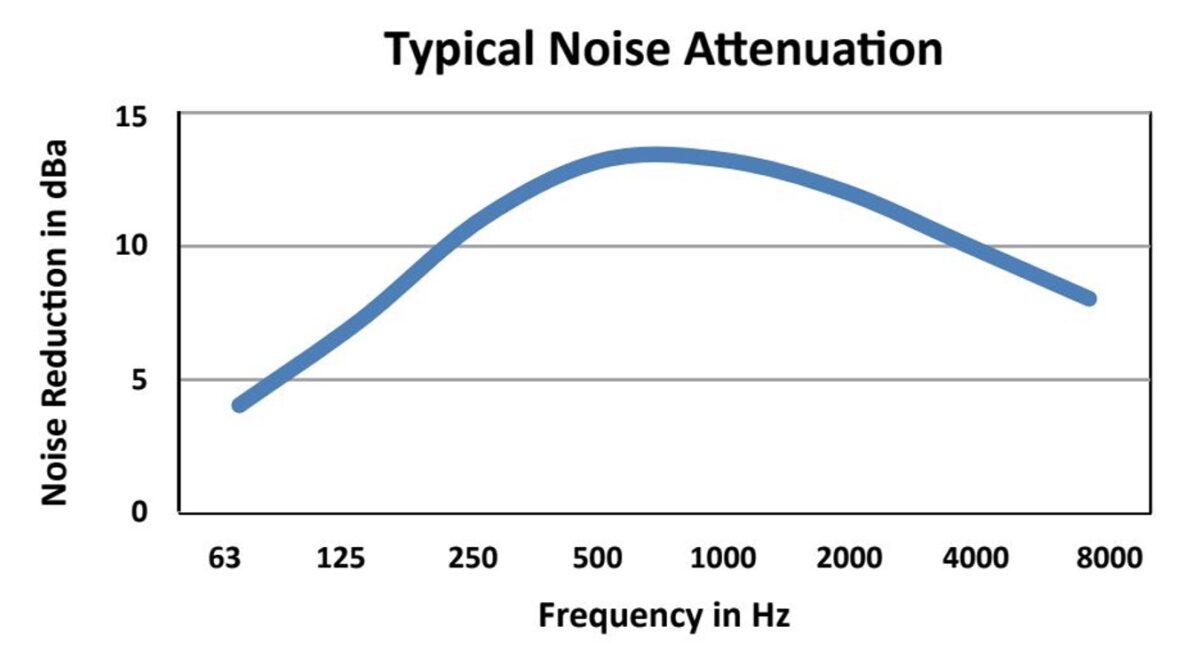

It is acceptable to not really answer this question until the type of equipment being used to create flow is analyzed and the appropriate silencer installation location and its type is confirmed. Please consider this very general 0-14 dBa curve illustrating the possibilities:

Can conventional silencers be used in fuel cell and hydrogen applications or do they need to be adapted?

This depends on the flow equipment but generally, the answer is yes. A lot of all the gas-moving equipment has already been around for decades and therefore so has the silencing technology. However, adaption done in cooperation with experienced supplier is likely to achieve superior results.

Which materials are used in silencers to reduces the noise level?

Absorptive material like fiberglass, polyester, Nomex, etc.. For the reactive fuel cell silencer, heavy steel is used. The reactive silencers are a complex design of torturous flow paths for the flow and noise. The material absorbs the sound and typically the byproduct is heat.

Which design measures can further reduce the noise level of fuel cell systems in addition to the use of silencers?

Working in combination with the filtration systems, a filter silencer for fuel cell systems also increases their efficiency and sustainability. But different solutions to minimize the noise in a fuel cell system exist. A variety of silencing solutions are available, which fit different types of components and systems and will make fuel cells run quieter.

Fuel cell manufacturers regularly encounter new design challenges when adapting their products to specific applications, installation scenarios, operating conditions, and individual client requirements. A unique and individual approach is needed to develop dedicated fuel cell silencer solutions in line with the respective filtration, flow, and noise level requirements. This can be achieved by drawing on the wealth of experience of established manufacturers and their proven fuel cell silencer designs on offer, which form the fundamental prerequisite for new designs and developments.

Content contributed by Solberg International

With more than 50 years of experience in the development and production of filtration solutions, the name SOLBERG stands for expertise in filtration like no other. By taking particles, liquids, steam, oil mist and harmful gases out of the air stream, we protect all kind of machines and at the same time the environment. We want to help our partners to innovate, to find new ways and solutions to enhance their technologies and make power generation more sustainable. For this reason, Solberg developed specific filtration solutions for fuel cells, which we think, will be an important part in the futures energy storage market. Please feel free to contact us for your individual application, that we can find the best solution for your problem together.

Last update: 15.1.2023