- What is a fuel cell humidifier?

- How does a fuel cell humidifier work?

- Do different types of fuel cell humidifiers exist? What are they?

- Classification of Fuel Cell Humidifiers:

- Do fuel cell stacks require a humidifier?

- What are the main interfaces in a fuel cell humidifier?

- What are the key performanance criteria of fuel cell humidification systems?

- How does a fuel cell humidifier affect the operation and efficiency of a fuel cell system?

- What should be the ideal humidity level of a fuel cell system?

- What happens if one does not use a fuel cell humidifier in a fuel cell system?

- What should be considered during maintenance of a fuel cell humidifier?

- How long is the lifetime of a fuel cell humidifier?

Browse fuel cell humidifiers from leading suppliers on our marketplace!

What is a fuel cell humidifier?

In the operation of a PEMFC, water management is very important since proton conductivity of the polymer electrolyte membrane, which plays a critical role in determining the cell performance, is proportional to the hydration level of the membrane. A variation of relative humidity from 85 to 35% causes a full order of magnitude reduction of the protonic conductivity of Nafion from 0.09 to 0.009 Scm. Principally, a fuel cell needs to be hydrated using a fuel cell humidifier. Excess water causes diffusion of the reactant gases towards catalytic layers. This reduces the cell performance along with losses due to concentration, polarization and mass transportation. To obtain high performance and good proton conductivity it is essential to maintain optimal water content in the membrane. This is achieved by feeding humidified reactant gases through a humidifier.

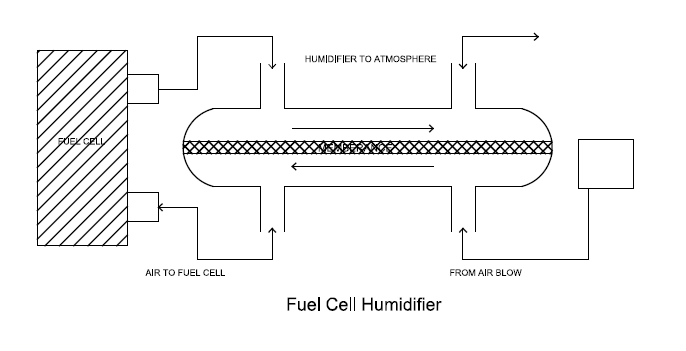

How does a fuel cell humidifier work?

A fuel cell humidifier protects the fuel cell membranes against drying out. In addition, the humidifier provides humidity by transferring water vapor from the exhaust gases to the intake gases. The gases which are sent to the fuel cell are humidified to maintain the optimal hydration level of the membrane.

Do different types of fuel cell humidifiers exist? What are they?

Different types of humidifiers exist in the market based on various applications.

Classification of Fuel Cell Humidifiers:

a) Based on humidification method

- Gas-to-gas humidification

- Water-to-gas humidification

b) Based on humidification type

- Recirculating humidifier

- Hollow fiber membrane humidifier

- Flat membrane humidifier

c) Based on humidifier design

i) Internal humidification

- Special stack design

- Direct liquid injection

- Membrane additive

- Wicks, sponges & porous plates

ii) External humidification

- Bubbler humidifier

- Enthalpy wheel humidifier

- Membrane based humidifier

Do fuel cell stacks require a humidifier?

The water produced internally by the oxidant reduction reaction is generally not enough to ensure sufficient hydration of the electrolyte membrane everywhere in the cell. The drying effect of the reactant streams removes this product water from the GDL and leaves the membrane dry, especially at the beginning of the flow field channels. To compound the problem, while it is desirable to operate the fuel cell at higher temperatures in order to minimize activation losses, the resulting drying effect however becomes more pronounced at higher temperatures due to the exponentially increasing nature of the saturation vapor pressure curve. Humidification is necessary to ensure the entire membrane area is well humidified. A more humidified membrane has a higher protonic conductivity and a longer lifetime. Fuel cells must therefore be integrated with fuel cell humidifier modules as a matter of course so as to achieve optimum performance.

Stack humidification may be achieved using different methods, and designs. The selection of the humidifier is based on the application. When considering a laboratory test system, the reactant gas is usually humidified by passing it through a water bath in a bubble humidifier that is controlled at a desired temperature. This process assumes that the dew point of the air is the same as the temperature of the bubble humidifier. This temperature can be controlled independently of the cell temperature to achieve the desired RH value of the gas. Water vapor is absorbed by the gas, and water uptake is a function of the water-gas interface area. This is a conventional humidification method and is widely used in small-scale laboratory fuel cells due to its simplicity and low cost, but it is not very practical for use in large-scale stacks.

What are the main interfaces in a fuel cell humidifier?

The fuel cell humidifier consists of various parts which causes the incoming gases to become humidified. Different parts will be used depending on the type of humidifier selected. The various parts of the conventional humidifier are an input channel for incoming hot gases and an output channel for outgoing cool gases. Based on the type of humidifier selected, a separation membrane, plate or tube is provided in the humidifier to separate the hot and cool gases.

What are the key performanance criteria of fuel cell humidification systems?

The humidifier is an important consideration in the design of a fuel cell. The humidifier needs to be able to maintain stable, accurate reactant humidity and flow levels to the fuel cell at all times. The response time, or the speed at which a desired humidity level can be reached, is also a consideration for some users. As mentioned previously, some humidification methods can more rapidly achieve or change the humidification level than other schemes. The humidifier also needs to be able to supply anode and cathode flow rates sufficient for the fuel cell.

The performance and durability of a PEMFC humidifier depends on the stability, accuracy and capacity of the humidification system of the fuel cell. The stability of a humidifier is an important factor for the required flow rate of the fuel cell that needs to be maintained. The flow rate of the gases determines the stability of the humidifier. The accuracy of the humidifier in maintaining the required humidity level of the incoming gases affects the performance of the fuel cell. The same humidity level should be maintained for every cycle so as to achieve optimum performance. The capacity of the humidifier needs to be considered to match the capacity of the fuel cell. There should be no flow restrictions from the humidifier to the fuel cell.

The other required criteria of a fuel cell humidifier are temperature & thermal mass. Temperature is the one parameter with the highest impact on the performance of the fuel cell humidifier. The higher the temperature the greater the water vapor content of the supplied gas. The total contact surface area over which the incoming hot gas into the humidifier is in contact with the outgoing cool gases is one of the key performance parameters affecting the overall efficiency of the fuel cell.

How does a fuel cell humidifier affect the operation and efficiency of a fuel cell system?

The humidifier improves the efficiency of the fuel cell and its fuel cell stack by reducing or eliminating dehydration of the electrolyte membrane. The lifetime of the membrane-based electrolyte increases due to incoming humidified gases. The fuel cell life expectancy is based on the membrane life. Therefore, the fuel cell needs to maintain the humidity of the membrane, which increases the efficiency of the fuel cell.

What should be the ideal humidity level of a fuel cell system?

The ideal humidity level should be maintained in the fuel cell for proper operation. Air humidity should be above 80% so to avoid excessive drying and it must be below 100% to avoid possible flooding at the electrodes.

What happens if one does not use a fuel cell humidifier in a fuel cell system?

Operation of a fuel cell without a fuel cell humidification system causes the electrolyte membrane to become dehydrated. This leads to punctures in the membrane which will reduce the overall efficiency of the fuel cell system. All commercial fuel cells use a humidifier to obtain optimum performance of the fuel cell. Either the fuel cell requires implementation of an internal humidification system, otherwise external humidification is used for better efficiency and life expectancy of the fuel cell.

What should be considered during maintenance of a fuel cell humidifier?

Repeated usage of the fuel cell humidifier reduces the life expectancy of the humidifier. So, maintenance of the fuel cell humidifier is very important for improving the efficiency of the humidifier which in turn increases the efficiency of the fuel cell. Proper maintenance of the humidifier requires an efficient cleaning system, so as to achieve high performance and longer life. This is used to clean the humidifier gas separation membrane from dust and obstacles. The humidifier walls should be clear of all types of small particles formed due to moisture.

How long is the lifetime of a fuel cell humidifier?

The lifetime of a PEM fuel cell humidifier is the most important parameter, which can have an impact on all the other factors. Therefore, there is growing interest in research on fuel cell humidifier performance in order to develop durable fuel cell humidification systems and integrate them into practical applications in the near future. The life of the fuel cell humidifier depends on the operating parameters and efficiency of the humidifier. The maximum lifetime of a fuel cell humidifier is 18,000 to 20,000 hrs.

It was reported that the degradation of the membrane electrode assembly (MEA) occurred under low humidity conditions or in case no humidification of reactant gases took place. In turn, no significant degradation was observed under saturation humidification of the feed stream. However, the understanding of the actual mechanism responsible for degradation of the MEA under conditions of low humidity remains ambiguous to date.

Last update: 13.01.2023