Operating principles of cathode fuel cell blowers in stationary fuel cell systems

- What is the main function of a cathode blower?

- Which type of cathode blower is used to supply air in stationary fuel cell applications?

- Which are the guiding design principles when integrating cathode air compressors in a fuel cell system?

- How do compression principles differ between the different types of cathode air compressor?

- Which are the typical pros and cons and typical application areas of different cathode air compressor types?

- See the educational video on cathode fuel cell blowers

Browse fuel cell air compressors from leading suppliers on our marketplace!

What is the main function of a cathode blower?

Fuel cells require oxygen on the cathode side for their electrochemical reactions. The normal gas exchange at the cathode is not sufficient for fuel cells with higher power ratings to supply them with enough oxygen.

For this reason, stack manufacturers (for commercially available PEM and SOFC) specify an air flow rate and pressure on the cathode side.

Which type of cathode blower is used to supply air in stationary fuel cell applications?

Stationary fuel cell systems usually require only a cathode blower, not an anode recirculation blower. This article focuses on the stationary applications which require a cathode air blower. There are different fuel cells on the market – commercially available are the PEM (Polymer Electrolyte Fuel Cell) and SOFC (Solid Oxide Fuel Cell) types.

Which are the guiding design principles when integrating cathode air compressors in a fuel cell system?

The pressure on the cathode side is specified by the fuel cell stack manufacturer and the system manufacturer implements this. Here, the stack manufacturer tries to enable a high efficiency for the fuel cell itself, but also aims to keep the parasitic power loss for the cathode air compressor low. This is of particular importance, because the power required for compression increases with pressure. The systems designer will consider the following key factors in the decision-making when integrating a cathode air blower:

– Efficiency

– Robustness

– compactness, integrability and connectivity (e.g. field buses)

– avoidance of multiple dc/dc converter (-> DC drive)

– cold-start-up ability, controllability

How do compression principles differ between the different types of cathode air compressor?

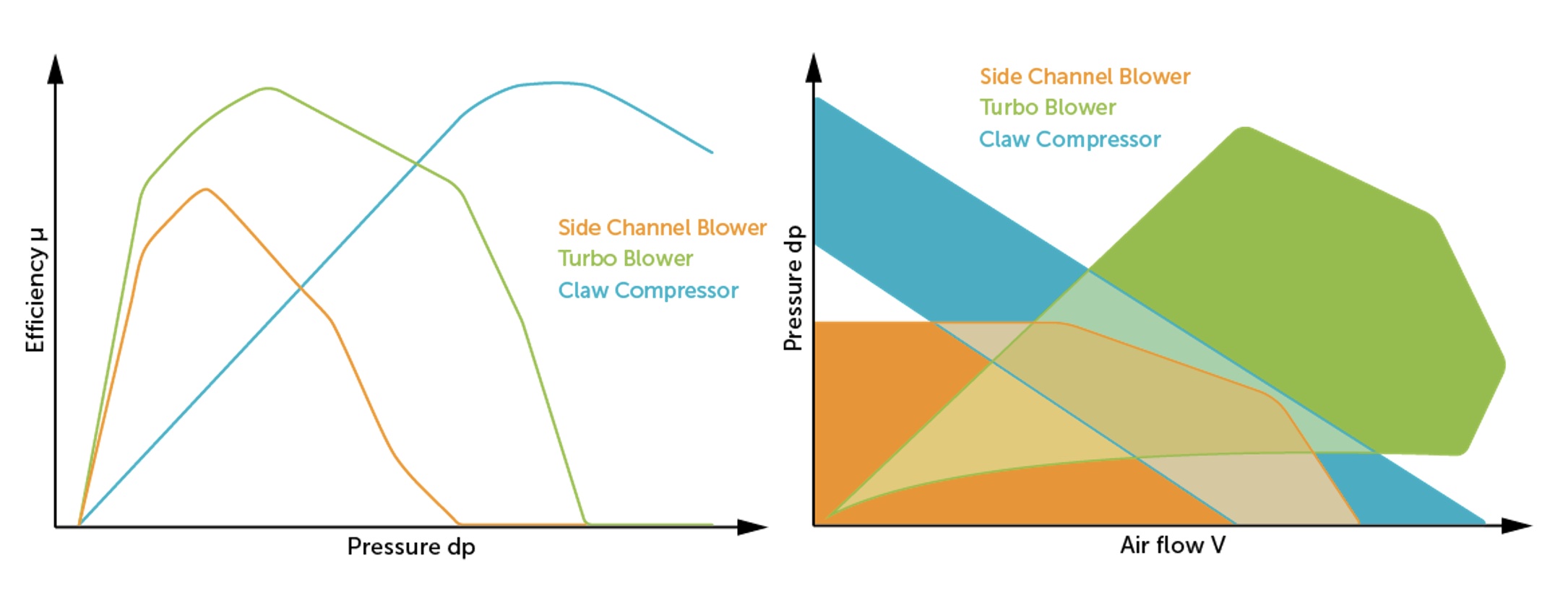

In purely schematic terms, the properties of the relevant air compressing principles (side channel blower, radial blower and claw pumps) can be illustrated as follows:

1. Side Channel Blower

The side channel compressor is a continues flow machine. Compression is created by the airflow entrained by the blades.

Due to their design, side channel air blowers are robust, inexpensive, and generate moderate pressure at moderate speeds. They are maintenance-free and oil-free.

The characteristic diagram above shows that side channel blowers are designed in principle for operation without flow, i.e. they will survive a clogged filter without any problems.

The mechanical efficiency will reach up to 45%.

2. Claw Pump

Claw pumps are positive displacement machines suitable for generating pressures +100mbar – +2bar. They are potentially oil-free and achieve high efficiency between +500mbar and +1500mbar.

The mechanical efficiency will reach up to 55%.

3. Centrifugal Blower (Radial Blower/Turbo Blower)

The centrifugal blower is a continuous-flow machine, the pressure build-up is generated by centrifugal forces of the accelerated air.

Radial blowers need higher speeds for the medium pressure build-up. As a result, a centrifugal blower with low final pressures have a simple design. Blowers with higher flow rates and higher pressures have an elaborate design.

The performance map of a radial blower is curtailed by the surge limit. If the flow rate is too low, a stall occurs with a potential hazard to the pump. Electronic or mechanical countermeasures can be taken.

Centrifugal blowers, with the appropriate design, are characterized by very high efficiencies of up to 70% mechanically.

4. Screw Pump

Theoretically usable, however the practical use with fuel cells unknown.

Which are the typical pros and cons and typical application areas of different cathode air compressor types?

|

Blower type

|

Advantages

|

Disadvantages

|

Typical application

|

|

Side channel

|

EconomicalRobustMaintenance-free

|

Limited efficiency

|

SOFC systems >3KW with moderate pressure requirements

|

|

Claw type

|

High pressures possible

|

Maintenance of gearboxCosts

|

Mobile applicationsFuel cells with high power density or designed for higher pressure

|

|

Radial blower

|

High efficiencyMaintenance freeEconomical design for low pressures sufficient

|

Elaborate design for higher pressures needed

|

|

See the educational video on cathode fuel cell blowers

Content contributed by Becker International

Gebr. Becker was founded in 1885 as „Maschinenfabrik Gebr. Becker“ in Wuppertal-Barmen. Today Becker is, in 4th generation owner-managed. A global leading manufacturer of vacuum and pneumatic equipment. Renowned throughout the world and in many industrial sectors, Becker’s vacuum pumps, compressors and pneumatic systems are available as single components and complete system solutions. Approximately 120.000 devices and systems are produced in the plants every year. The export contingent is 80 percent. With many innovative products and designs, state-of-the art manufacturing technology and future-oriented strategic investments, combined with stable family ownership, both customers and suppliers alike rely on Becker as a fair partner. Becker is supplying cathode blowers for systems with mid-sized fuel cell power.

Last update: 15.1.2023