TOPAQ Hydrogen Parallel Charging Unit - H2Rail

Poppe + Potthoff GmbH- Hydrogen parallel charging unit to connect several tanks to distribute the hydrogen during refueling and harmonize it during unloading

- Usable for hydrogen storage systems, mobile and stationary applications

- Nominal working pressure up to 700 bar

- Certified according to EC79 (350 and 700 bar)

- Available in stainless steel and specially designed PPH2 material group

- Part of TOPAQ Hydrogen Supply System

Hydrogen parallel charging unit - H2Rail

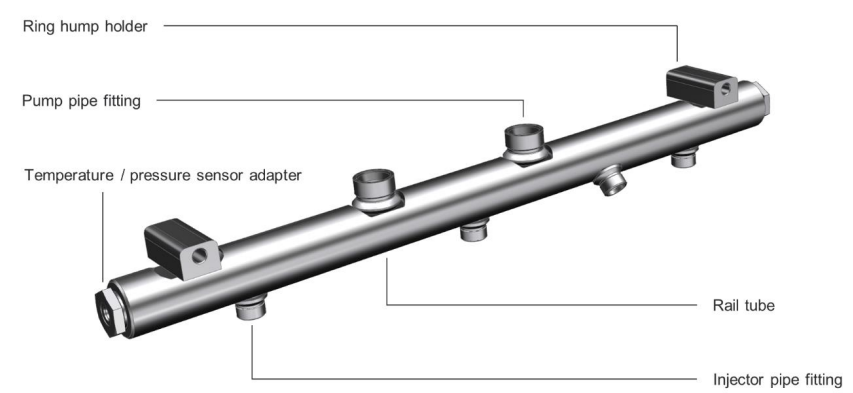

- H2 rails are used in direct injection processes to ensure the safe supply of hydrogen with an even distribution to the injectors while reducing pressure pulsations.

- In order to homogeneously distribute the hydrogen to several storage tanks during the fueling process, they can also be used as distribution rails in storage and distribution systems of vehicles and stationary applications.

- By varying the rail dimensions and numbers and positions of the pipe fittings, it is possible to meet the customer's specifications and installation space requirements in the best possible way.

Key features

- Safe and even distribution of hydrogen from receptacle to tank to injectors

- Variable number of connection ports regarding the customer’s specification

- Suitable for 6.00, 6.35- and 10-mm Pipe-OD, further dimensions possible

- Nominal working pressure up to 700 bar

- Operating temperature: -40 to +120 °C

- Well established and leak tight Metal-to-Metal-Sealing

- Material: PPH2 or Stainless Steel

- Variable rail dimensions and number and position of pipe connections to meet the customer's specifications and installation space requirements

- Due to its material qualities, PPH2 enables significant weight and cost reduction

- Optional equipped with pressure and temperature sensor, check valve and filter

- Reduced pressure pulsations

- Angle compensation of up to 10° due to P+P interface compensates for small manufacturing tolerances and removes stresses from the system for an easy and fast assembly

- Customized designs possible thanks to agile development for the respective use case

Product specifications

Applications

- Mobile applications, such as passenger cars or heavy duty

- Stationary applications

- Storage systems

Contact us

- Interested? Please contact Poppe+Potthoff by filling in the contact vendor form.

| Max Pressure (in bar) | 700 |

| Diameter (in mm) | 30 |

| Compliant with | EC79 |

| Max Ambient Temperature (in °C) | 120 |

| Min Ambient Temperature (in °C) | -40 |

Poppe + Potthoff is a partner to global OEMs and Tier 1 suppliers in technically demanding industries such as automotive, heavy duty, mechanical engineering, marine and aerospace. Founded in Werther in 1928, we have developed into an international group with over 1,600 employees. As a development partner for zero-emission drives in mobility and industry, we develop and supply modular and smart 'TOPAQ' hydrogen supply systems. We take a holistic approach to designing all key components for H2 supply from the tank to the fuel cell or hydrogen engine. In particular, this includes on-tank valves, H2 rails, TPRDs, HPRUs and pipes. In addition, we develop and manufacture innovative testing systems for the continuous quality optimisation of H2 components and for shortening development cycles.